G73 / G83 Peck Drilling Reposition Location - Mach4

Symptoms

- The Z axis does not retract far enough and chip does not sufficiently clear from the drill flutes. Increase HSP.

- Z retracts too far and the cycle time is unnecessarily long. Reduce HSP

- When feeding in, the Z axis switches from rapid rate to feed rate too soon, and increases the cycle time. Reduce FRP.

Solution

Mach4 has two machine parameters that affect the reposition behavior with regards to peck drilling. There are multiple ways to change those values.

Current Mach 4 Mach Parameters

In versions after 4.2.0.3779 (2018-05-04) these parameters have been moved to the Mach Parameters. You can set these values in the MachMotion plugin, in the G-Code, or on the dashboard after adding the appropriate widget. For older version - before 2018, see the Older Mach 4 pound variables section below.

- The values are in increments of .0001" or .001mm.

-

Default values for HSP and FRP have changed over different releases

- The default value for HSP 5114 is 250 (.0250) or 600 (.600mm) [or 1000 (.1000")]

- The default value for FRP 5115 is 100 (.0100") or 250 (.250mm)

MachMotion Plugin

To change the values in the MachMotion plugin disable the control, then pull down Configure | Plugins | MachMotion

G-Code

Add these lines to your G-Code above the G73 or G83 lines. Adjust the values for each parameter to suit your needs.

G10 L50

N5114 R250 (HSP = 0.0250")

N5115 R100 (FRP = 0.0100")

G11Dashboard Widget

You can also add these parameters to the dashboard and rename the labels. The dashboard parameter values can be changed by clicking in the value field and entering a new value.

|

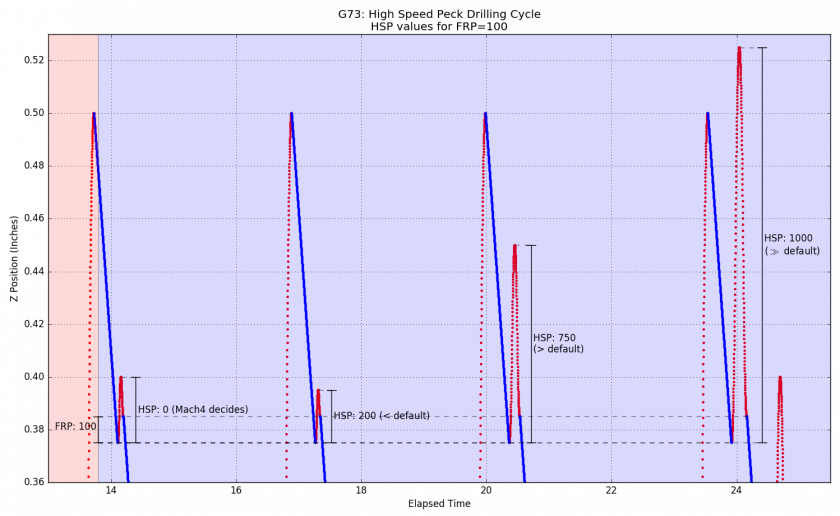

HSP and FRP meaning

SV_HSP_CLEARANCE / #5114

High Speed Peck (HSP) drilling cycle (G73) rapid retract clearance.

(integer specifying .0001" or .001mm increments, depending on machine units)

This parameter defines how far the tool retracts away from the bottom of each peck. Increase this value until the chips are consistently clearing from the flutes of the tool.

G83 always fully retracts to the retract plane; therefore HSP values do not affect G83 motion.

G code Examples

Machine units are inches

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G10 L50 (Set offsets)

N5114 R250 (HSP = 0.0250")

N5115 R100 (FRP = 0.0100")

G11 (Clear offsets)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G73 G99 X1.0 Y-1.0 Z-1.0 Q0.1 R0.25 F10 (Peck drill cycle start)

X2.0 Y-1.0 (Drill second hole)

X3.0 Y-1.0 (Drill third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%Machine units are millimeters

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G10 L50 (Set offsets)

N5114 R600 (HSP = 0.600 mm)

N5115 R200 (FRP = 0.250 mm)

G11 (Clear offsets)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G73 G99 X1.0 Y-1.0 Z-1.0 Q0.1 R0.25 F10 (Peck drill cycle start)

X2.0 Y-1.0 (Drill second hole)

X3.0 Y-1.0 (Drill third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%SV_FRP_CLEARANCE / #5115

Full Retract Peck drilling cycle (G73, G83) rapid clearance before feed starts.

(integer specifying .0001" or .001mm increments, depending on machine machine units)

While the tool is moving in to start the next peck, you can have it move at a rapid rate. The FRP value is the distance above the bottom of the previous peck at which you want this move to switch from a rapid to a feed rate move.

You can tune your cycle times by keeping your HSP values to the smallest distance necessary to clear the chip, and keeping your FRP values to the smallest value necessary for the motion to safely change to a feed rate before reaching the part.

The G83 Full Retract Peck Drilling cycle behaves the same as G73, except every rapid retract goes to the retract plane (R parameter). Only the FRP parameter affects the G83 behavior.

G code Examples

Machine units are inches

G10 L50

N5115 R100 (Set FRP to 0.01")

G11

G83 X0 Y0 Z-2 R.5 Q.5 F20G10 L50

N5114 R500 (Set HSP to 0.05")

N5115 R100 (Set FRP to 0.01")

G11

G73 X0 Y0 Z-2 R.5 Q.5 F20Machine units are millimeters

G10 L50

N5115 R250 (Set FRP to 0.025mm)

G11

G83 X0 Y0 Z-50.8 R12.7 Q12.7 F500 G10 L50

N5114 R250 (Set HSP to 0.025mm)

N5115 R100 (Set FRP to 0.010mm)

G11

G73 X0 Y0 Z-50.8 R12.7 Q12.7 F500Older Mach 4 pound variables

In versions of Mach 4 older than 4.2.0.3779 (prior to 2018-05-04) these were pound variables. The meaning of the parameters is the same as described above. The values can be changed in G-Code like this:

HSP examples for G73:

(Inch example)

#5114=250

G73 X0 Y0 Z-2 R.5 Q.5 F20(MM example)

#5115=100

G73 X0 Y0 Z-50.8 R12.7 Q12.7 F500FRP examples for G83 and G73:

(inch example)

#5115 = 100 (0.01")

G83 X0 Y0 Z-2 R.5 Q.5 F20

#5115 = 100 (0.01")

G73 X0 Y0 Z-2 R.5 Q.5 F20

(MM example)

#5115 = 250 (0.25mm)

G83 X0 Y0 Z-50.8 R12.7 Q12.7 F500

#5115 = 100 (0.01")

G73 X0 Y0 Z-50.8 R12.7 Q12.7 F500

Keywords: 14513