Mach4 G-Code and M-Code Reference

Introduction

G-code is a special programming language that is interpreted by Computer Numerical Control (CNC) machines to create motion and other tasks. It is a language that can be quite complex at times and can vary from machine to machine. The basics, however, are much simpler than it first appears and for the most part follows an industry adopted standard. Mach4 has made a large leap closer to this standard.

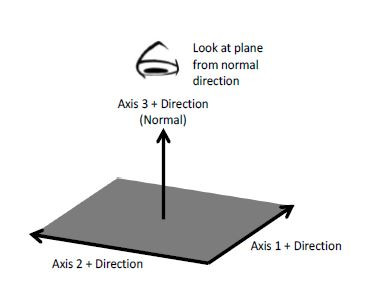

An important point to remember when reading this manual: In describing motion of a machine it will always be described as tool movement relative to the work piece. In many machines the work piece will move in more axes than the tool; however the program will always define tool movement around the work piece. Axis directions follow the right hand rule, see figure A.

Glossary

| Block | A single line of g-code |

| Canned Cycle | Complex cycle defined by a single block of code, used to simplify programming |

| Dwell | Program pause with a duration defined by “P” in seconds. If “P” contains a decimal point, the time is in seconds. |

| EOB |

End of block. Required at the end of every block of G-Code. In Mach4 this is a carriage return |

| Feedrate | Velocity, set by F, at which an axis will move |

| Group |

Collection of G-Codes that control the same function or mode, i.e. G90 and G91 positioning modes |

| Modal | Active until a code from the same group is called |

| Normal | A line perpendicular to a plane, pointing in the positive direction. |

| Origin | Point in a coordinate system where X, Y and Z are zero |

| RPM | Revolutions per minute |

| UPM | Units per minute (inches, millimeters, degrees, etc.) |

| Word | A single word of g-code is a letter followed by a number. G01, X1.0, etc. are words |

| G | Preparatory function, G followed by a numerical code, specifies machining modes and functions |

| M | Miscellaneous function, M followed by a numerical code, defines program flow and can control auxiliary functions such as coolant. Can also perform machine specific functions and macros user or builder. |

| X, Y, Z, A, B, C | Movement command followed by a numerical value, define the end point of a motion command |

| S | Spindle speed, followed by numerical value of desired RPM or surface speed |

| T | Tool call, followed by next tool number to be used |

| H | Tool height offset to be used, generally matches the tool number |

| D | Tool diameter offset to be used, generally matches the tool number |

| N | Sequence numbers. Used for program organization and go to commands |

Format

In writing g-code programs there are some rules to be aware of as well as some general formatting guidelines that should be followed or at least considered.

The first part of any program should be a safe start up block. This line of code is used to make sure that some modes are disabled and others are set to their most common setting. An example safe start block would look like this:

G00 G90 G17 G54 G40 G49 G80This block of code tells the machine that we want to be in rapid mode and using absolute position in the XY plane of fixture offset 54 (the first fixture offset). At the same time we want to cancel any tool diameter and length offsets and make sure any active canned cycles are cancelled.

G00 (Rapid mode)

G90 (Absolute position mode)

G17 (XY plane select)

G54 (Fixture offset 1)

G40 (Cutter compensation cancel)

G49 (Length offset cancel)

G80 (Canned cycle cancel)It is recommended that this safe start block be used at the start of the program and also before or immediately following every tool change. It is common to restart a program from a tool change, having the safe start line there can greatly reduce the chance of a machine not acting as expected, the results of which can be aggravating at best and a crash at worst. The safe start block shown here is just an example. Every machine and every programmer are a little different and each will have their own start up block.

Jumping to the end of the program there is not a lot required. Typically there will be a couple blocks of code to return the Z axis to the home position and maybe move the work piece closer to the operator for easier loading and unloading of parts. Shutting off the spindle and coolant or any other accessories is also a good idea here. The final block in a program is a program end code, most commonly M30 but there are other options. Make sure this final block is followed by an end of block. It is easy to forget this last EOB in a program for Mach because it is just a carriage return and not always readily apparent. One way to make sure that there is always an EOB on your program end block is to follow it with %. Like this:

(program body)

M30 (program end and rewind)

%

This percent sign is a familiar symbol to CNC programmers in industry; however any symbol or character can be used as it will not be read by the control because of the program end before it. If there is no EOB following the percent sign it will not show up in the program when loaded into Mach.

In between the start and end is the body of the program. There are a few rules here. Each block of code will contain a combination of words. Multiple g-codes can be specified in a single block, however if more than one from the same modal group is specified the last one in the block will be valid, with the exception of group 00. Modal g-cdes stay active until another from the same group is called. For example; G01 is modal so it is not necessary to put it in consecutive blocks. Once active every successive positioning block will be in the G01 mode unless another code from group one is called (G00, G02, G03, etc.). All g-codes not in group 0 behave this way.

Only one m-code can be specified in a single block. Same holds true for all other words.

Generally leading zeroes are not required in g-code. For example G01 and G1 are the same. The same holds true for m-codes, position commands, feedrates, etc. When specifying values for position, feedrate, variables, etc., it is good practice to always use a decimal point and trailing zero, instead of X1 use X1.0. Although the decimal point is not required (in Mach X1 = X1.0) it is HIGHLY recommended.

G-Code List

| Code | Group | Description | Modal |

| G00 | 1 | Rapid Move | Yes |

| G01 | 1 | Linear Feed Move | Yes |

| G02 | 1 | Clockwise Arc Feed Move | Yes |

| G03 | 1 | Counter Clockwise Arc Feed Move | Yes |

| G04 | 0 | Dwell | No |

| G09 | 0 | Exact Stop | No |

| G10 | 0 | Fixture and Tool Offset Setting | No |

| G12 | 1 | Clockwise Circle | Yes |

| G13 | 1 | Counter Clockwise Circle | Yes |

| G15 | 17 | Polar Coordinate Cancel | Yes |

| G16 | 17 | Polar Coordinate | Yes |

| G17 | 2 | XY Plane Select | Yes |

| G18 | 2 | ZX Plane Select | Yes |

| G19 | 2 | YZ Plane Select | Yes |

| G20 | 6 | Inch | Yes |

| G21 | 6 | Millimeter | Yes |

| G28 | 0 | Zero Return | No |

| G30 | 0 | 2nd, 3rd, 4th Zero Return | No |

| G31 | 1 | Probe Function | No |

| G32 | 1 | Threading* | No |

| G40 | 7 | Cutter Compensation Cancel | Yes |

| G40.1 | 18 | Arc Type Cutter Compensation | Yes |

| G40.2 | 18 | Line Offset Type Cutter Compensation | Yes |

| G41 | 7 | Cutter Compensation Left | Yes |

| G42 | 7 | Cutter Compensation Right | Yes |

| G43 | 8 | Tool Length Offset + Enable | Yes |

| G44 | 8 | Tool Length Offset - Enable | Yes |

| G49 | 8 | Tool Length Offset Cancel | Yes |

| G50 | 11 | Cancel Scaling | Yes |

| G51 | 11 | Scale Axes | Yes |

| G52 | 0 | Local Coordinate System Shift | Yes |

| G53 | 0 | Machine Coordinate System | No |

| G54 | 14 | Fixture Offset 1 | Yes |

| G54.1 | 14 | Additional Fixture Offsets | Yes |

| G55 | 14 | Fixture Offset 2 | Yes |

| G56 | 14 | Fixture Offset 3 | Yes |

| G57 | 14 | Fixture Offset 4 | Yes |

| G58 | 14 | Fixture Offset 5 | Yes |

| G59 | 14 | Fixture Offset 6 | Yes |

| G60 | 0 | Unidirectional Approach | No |

| G61 | 15 | Exact Stop Mode | Yes |

| G64 | 15 | Cutting Mode (Constant Velocity) | Yes |

| G65 | 0 | Macro Call | No |

| G66 | 12 | Modal Macro Call | Yes |

| G67 | 12 | Modal Macro Call Cancel | Yes |

| G68 | 16 | Coordinate System Rotation | Yes |

| G69 | 16 | Coordinate System Rotation Cancel | Yes |

| G73 | 9 | High Speed Peck Drilling | Yes |

| G74 | 9 | LH Tapping* | Yes |

| G76 | 9 | Fine Boring* | Yes |

| G80 | 9 | Canned Cycle Cancel | Yes |

| G81 | 9 | Hole Drilling | Yes |

| G82 | 9 | Spot Face | Yes |

| G83 | 9 | Deep Hole Peck Drilling | Yes |

| G84 | 9 | RH Tapping | Yes |

| G84.2 | 9 | RH Rigid Tapping* | Yes |

| G84.3 | 9 | LH Rigid Tapping* | Yes |

| G85 | 9 | Boring, Retract at Feed, Spindle On | Yes |

| G86 | 9 | Boring, Retract at Rapid, Spindle Off | Yes |

| G87 | 9 | Back Boring* | Yes |

| G88 | 9 | Boring, Manual Retract | Yes |

| G89 | 9 | Boring, Dwell, Retract at Feed, Spindle On | Yes |

| G90 | 3 | Absolute Position Mode | Yes |

| G90.1 | 4 | Arc Center Absolute Mode | Yes |

| G91 | 3 | Incremental Position Mode | Yes |

| G91.1 | 4 | Arc Center Incremental Mode | Yes |

| G92 | 0 | Local Coordinate System Setting | Yes |

| G92.1 | 0 | Local Coordinate System Cancel | Yes |

| G93 | 5 | Inverse Time Feed | Yes |

| G94 | 5 | Feed per Minute | Yes |

| G95 | 5 | Feed per Revolution* | Yes |

| G96 | 13 | Constant Surface Speed* | Yes |

| G97 | 13 | Constant Speed | Yes |

| G98 | 10 | Initial Point Return | Yes |

| G99 | 10 | R Point Return | Yes |

* Implementation based on machine and control configuration

For clarity rotational moves have been omitted from this manual. All motion commands can also contain A, B, and/or C axis motion.

G00: Rapid Move

Rapid moves are used to move from point to point in free space, not cutting material. These moves do not require a feed rate input as they take place at max velocity of the machine. In absolute position mode (G90) X, Y and Z define the end point of the move in the user coordinate system. In incremental position mode (G91) X, Y and Z define the distance and direction to move from the current position.

Format: G00 X_ Y_ Z_

Example: Program a rapid move to X1.0 Y3.0

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y3.0 (Rapid to XY position)

M30 (Program end and rewind)

%

G01: Linear Feed Move

Linear feed moves are point to point moves in a straight line at a feedrate specified by F. The moves are interpolated so all axes in motion reach the end point at the same time. In absolute position mode (G90) X, Y and Z define the end point of the move in the user coordinate system. In incremental position mode (G91) X, Y and Z define the distance and direction to move from the current position.

Format: G01 X_ Y_ Z_ F_

Example: Program a feed move from X1, Y3, to X10, Y-1 at a feedrate of 15 UPM.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G94 (Feed per minute mode)

G00 X1.0 Y3.0 (Rapid to XY position)

G01 X10.0 Y-1.0 F15 (Move to XY position at feedrate)

M30 (Program end and rewind)

%

G02/G03: Arc Feed Move

Used to cut an arc at a federate specified by F. An arc is defined by its start and end points, its radius or center point, a direction, and a plane. Direction is determined by G02, clockwise, and G03, counterclockwise, when viewed from the plane’s positive direction (If XY plane is selected look down so that the X axis positive direction is pointing to the right, and the Y axis positive direction is pointing forward). See figure 2-1 for a graphic representation of the motion of a G02. The start point is the current position of the machine. Specify the end point with X, Y, and Z. The values input for the end point will depend on the current G90/G91 (abs/inc) setting of the machine. Only the two points in the current plane are required for an arc. Adding in the third point will create a helical interpolation.

Next is to specify the radius or the center point of the arc, only one or the other, not both.

-

To specify the radius, use R and input the actual radius of the desired arc, see Format 2. When an arc is created knowing only start and end points and a radius there are two possible solutions, an arc with a sweep less than 180° and one with sweep greater than 180°. The sign of the radius value, positive or negative, determines which arc will be cut, see figure 2-2. A positive value for R cuts an arc with sweep less than 180°. A negative value for R cuts an arc with sweep greater than 180°.

-

A more accurate and reliable way to define an arc is by specifying the center point, this is done with arguments I, J, and K, see Format 1. The center point must be defined in the current plane. I, J, and K correspond to X, Y, Z respectively; the current plane selection will determine which two are used. XY plane (G17) would use I and J for example. Mach has two settings for how I, J, and K should be specified, absolute and incremental. This setting can be changed by G-Code, G90.1 and G91.1, or in the general tab in the Mach configuration. This setting is independent of the G90/G91 setting. If arc center mode is set to incremental then I, J, K are the distance and direction from the start point to the center point of the arc. If arc center mode is set to absolute then I, J, K are the absolute position of the arc center point in the current user coordinate system.

Examples:

- Format 1:

- (G17) G02/03 X_ Y_ I_ J_ F_

- (G18) G02/03 X_ Z_ I_ K_ F_

- (G19) G02/03 Y_ Z_ J_ K_ F_

- Format 2:

- (G17) G02/03 X_ Y_ R_ F_

- (G18) G02/03 X_ Z_ R_ F_

- (G19) G02/03 X_ Z_ R_ F_

Example: Program an arc centered at 1.0, 0.0 in the XY plane with radius 2. Start point at 3.0,0.0 and sweep 90 degrees counter clockwise. Feedrate 10 UPM. (Arc center mode set to incremental)

Format 1:

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X3.0 Y0.0 (Rapid to XY start position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z rapid plane)

G94 (Feed per minute mode)

G01 Z0.0 F10 (Z plunge at feedrate)

G03 X1.0 Y2.0 I-2.0 J0.0 F10 (Arc move)

G00 Z0.5 (Rapid retract Z)

G00 G53 Z0.0 (Return Z to home)

M30 (Program end and rewind)

%

Format 2:

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X3.0 Y0.0 (Rapid to XY start position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z rapid plane)

G94 (Feed per minute mode)

G01 Z0.0 F10 (Z plunge at feedrate)

G03 X1.0 Y2.0 R2.0 F10 (Arc move)

G00 Z0.5 (Rapid retract Z)

G00 G53 Z0.0 (Return Z to home)

M30 (Program end and rewind)

%

Helical Interpolation

A helical interpolation is defined very similar to an arc. The only difference is the addition of the third coordinate of the end point. This third coordinate will define the height of the helix. See the following format for what this looks like in the XY plane:

- Format 1:

- G02/03 X_ Y_ Z_ I_ J_ F_

- Format 2:

- G02/03 X_ Y_ Z_ R_ F_

Example: Program a helix with radius 1.0 and center point 0.0, 0.0 in the XY plane, start point (0.0, .5), height 1.0 with initial Z at 0.0, feedrate 10 UPM. Arc sweep should be 270° clockwise. See figure 2-2 for the tool path.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X3.0 Y0.5 (Rapid to XY start position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z rapid plane)

G94 (Feed per minute mode)

G01 Z0.0 F10 (Z plunge at feedrate)

G02 X-0.5 Y0.0 Z-1.0 I0.0 J-0.5 F10 (Arc move)

G00 Z0.5 (Rapid retract Z)

G00 G53 Z0.0 (Return Z to home)

M30 (Program end and rewind)

%

G04: Dwell

A dwell is simply a pause in the program. The duration of the dwell is specified by P in milliseconds with no decimal point. If a decimal point is used, then P specifies seconds. Additionally, pound variables can be used to specify time (always milliseconds). No machine movement will take place during a dwell. No auxiliary codes will be turned off, i.e. if the spindle is on it will stay on, coolant will stay on, etc.

Format: G04 P_

The dwell time must always be greater than 1ms.

Example: Program a 5 second dwell after positioning to X1.0, Y1.0 (using no decimal point to specify milliseconds).

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y1.0 (Rapid to XY position)

G04 P5000 (Dwell for 5 seconds)

M30 (Program end and rewind)

%

Example: Program a 5 second dwell after positioning to X1.0, Y1.0 (using decimal point to specify seconds).

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y1.0 (Rapid to XY position)

G04 P5. (Dwell for 5 seconds)

M30 (Program end and rewind)

%

Example: Program a 5 second dwell after positioning to X1.0, Y1.0 (using a pound variable to specify milliseconds).

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y1.0 (Rapid to XY position)

#100 = 5000 (Store a millisecond value in a pound variable)

G04 P[#100] (Dwell for 5 seconds)

M30 (Program end and rewind)

%

G09: Exact Stop

G09 is a non-modal exact stop. Machine accelerations cause corners to be slightly rounded; when a true sharp corner is required G09 should be used. Although similar to G61 in function, G09 is not modal while G61 is. When G09 is included in a movement block, axis motion is decelerated to the end point of motion and the position is checked to be exactly as specified. This position check at the end of the move ensures that the machine actually reaches the desired position before moving onto the next block.

Format: G01 G09 X_ Y_ F_

Example: Program a 2.0 inch square centered at X0.0, Y0.0 with true sharp corners at X1.0, Y1.0 and X- 1.0, Y-1.0, feedrate 15.0 UPM

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G94 (Feed per minute mode)

G00 X-1.0 Y1.0 (Rapid to XY position)

G01 G09 X1.0 F15 (Move to position at feedrate, with exact stop at end)

G01 Y-1.0 (Move to position at feedrate)

G01 G09 X-1.0 (Move to position at feedrate, with exact stop at end)

G01 Y1.0 (Move to position at feedrate)

M30 (Program end and rewind)

%

Figure 9-1 shows what this square would look like, slightly exaggerated.

G10: Fixture and Tool Offset Setting

It is possible to set fixture and tool offsets in the program. This can be very useful for programming multiple fixtures that have known zero points, multi pallet machines, applying automatic compensation of tool wear, and many other situations that require changing offset values. G10 is also one of the least understood G-Codes and is therefore underutilized. Changing offset values in a program requires a bit of cautiousness, a mistake can easily result in ruined parts and damaged tools. When used properly however, G10 can add flexibility and safety to a program and machine, especially with automation and lights out capacity or inexperienced operators.

Starting with fixture offset setting the G10 block will look like the following: Format: G10 L2 PXYZABC

L selects the function of the G10 block, different values will have different functions. L2 is the designation for fixture offset setting. The value of P specifies which offset is being set. For the basic 6 fixture offsets P values are as follows:

| Fixture Offset | P |

| G54 | 1 |

| G55 | 2 |

| G56 | 3 |

| G57 | 4 |

| G58 | 5 |

| G59 | 6 |

The data for the fixture offset is set by X, Y, Z, A, B, C.

| X | X Axis Offset |

| Y | Y Axis Offset |

| Z | Z Axis Offset |

| A | A Axis Offset |

| B | B Axis Offset |

| C | C Axis Offset |

All values do not need to be specified, only the ones to be set. If, for example, a Z is not programmed it simply will not be changed in the fixture offset.

In G90, absolute, mode the values in the G10 line will be directly input into the fixture offset. When in G91, incremental, mode the values will be added to the desired fixture offset. This is a major difference in functionality and care should be taken to make sure the right mode is active for the desired effect.

Example: Set G56 fixture offset to X-8.0, Y-3.0, Z-5.0, A45.0 in a program.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G10 L2 P3 X-8.0 Y-3.0 Z-5.0 A45.0 (Set G56 fixture offset values)

M30 (Program end and rewind)

%

Additional fixture offsets, G54.1 Pxx, can also be set using G10. Setting of these offsets is the same, except it is done using L20. The legacy additional fixture offsets (see fixture offset section of this manual for more details) can still be set with G10. The following table shows the additional fixture offset P number and its corresponding G10 P number as well as the legacy offsets. Note that G54.1 P1 is the same offset as G59 P7, so G10 L20 P1 and G10 L2 P7 both set the same offset values.

| G54.1 P_ | G10 L20 P_ |

Legacy G59 P_ |

Legacy G10 L2 P_ |

| 1 | 1 | 7 | 7 |

| 2 | 2 | 8 | 8 |

| 3 | 3 | 9 | 9 |

| - | - | - | - |

| - | - | - | - |

| - | - | - | - |

| 248 | 248 | 254 | 254 |

Example: Set G54.1 P5 fixture offset to X3.0, Y3.4, Z-10.0 in a program.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G10 L20 P5 X3.0 Y3.4 Z-10.0 (Set G54.1 P5 fixture offset values)

M30 (Program end and rewind)

%

Work shift and head shift can also be set with G10. Work shift is set using G10 L2 P0. Head shift is set using G10 L20 P0. Notice the L20 for head shift. All other values are set in the same format as the other fixture offsets.

Tool offset setting requires just as much care as setting of fixture offsets. G90 and G91 affect the setting of offset values in the same way. G90 causes the current value to be over written with the value in the G10 block, while G91 adds the value from the G10 block to the current value.

Format: G10 L1 P_ Z_ W_ D_ R_ X_ U_ Y_ V_ Q_

Again, not all values are required, if omitted that value simply will not be set. L1 specifies tool offset setting, P is again the offset number to be set (offset #1 = P1, offset #2 = P2, etc.). The remaining arguments specify the type and value of offset to be set.

| Z |

Height offset |

| W | Height wear offset |

| D | Diameter offset |

| R | Diameter wear offset |

| X* | X offset |

| U* | X wear offset |

| Y* | Y offset |

| V* | Y wear offset |

| Q | Tool pocket |

*Future feature; not yet implemented

Example: Set height of tool offset #5 to 1.5. Add .05 to offset #2 diameter wear.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G10 L1 P5 Z1.5 (Set tool offset #5 height to 1.5)

G91 (Incremental mode)

G10 L1 P2 R0.05 (Add 0.05 to tool offset #2 diameter wear)

M30 (Program end and rewind)

%

G12/G13: Circle Interpolation

These codes are used to cut a circle using the current position as the center point. Words, I and J, define the radius of the circle and the lead-in direction. G12 will cut a circle in the clockwise direction and G13 will cut in the counterclockwise direction. It is also possible to cut a larger circular pocket by specifying Q for the start radius and P for the step over amount. This can be useful for cutting a circular pocket or an ID groove.

- Format 1: G12/13 I_ J_ F_

- Format 2: G12/13 I_ J_ P_ Q_

See figure 12-1 for a graphic of the motion. The current position will be the center of the circle.

Figure 12-1: Tool motion during circle interpolation

Example: Cut a 1.0 inch radius circle centered at X1.5 Y0.25. Lead-in along the X axis.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.5 Y0.25 Z0.25 (Rapid to start position)

G01 Z-0.1 F30 (Plunge Z into part)

G13 I1.0 F30 (Cut circle)

G00 G53 Z0.0 (Z axis to machine zero)

M30 (Program end and rewind)

%

Example: Cut the same circle but lead-in at 45°.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.5 Y0.25 Z0.25 (Rapid to start position)

G01 Z-0.1 F30 (Plunge Z into part)

G13 I0.7071 J0.7071 F30 (Cut circle)

(X = 1 * COS[45°] = 0.7071)

(Y = 1 * SIN[45°] = 0.7071)

G00 G53 Z0.0 (Z axis to machine zero)

M30 (Program end and rewind)

%

G15/G16: Polar Coordinates

To enable polar coordinate positioning command G16 in a program. The setting is modal and will remain active until G15, polar coordinate cancel, is commanded or the system is reset. In the polar coordinate mode movement end points are specified as a radius and angle, the origin of which is determined by the absolute/incremental position mode setting (see G90/G91). In absolute position mode the origin for positioning is the zero point of the user coordinate system. In incremental position mode the origin is the current position.

Format: G16

The current plane setting determines which word is radius and which is angle.

| Plane | Radius Axis | Angle Axis |

| G17 | X | Y |

| G18 | Z | X |

| G19 | Y | Z |

Linear and arc moves can be programmed in the polar coordinate mode. When programming arc moves with G02 and G03 use R to specify the arc radius.

Example: See figure 15-1 for the tool path display of the following program.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G16 (Enable polar coordinate mode)

G00 X1.0 Y45.0 (Move to radius 1 and 45° from origin)

G03 X1.0 Y135.0 R0.75 F60 (Arc move of radius 0.75, endpoint at radius 1.0 and angle 135°)

G01 X2.25 Y180.0 (Linear move to radius 2.25, angle 180°)

G03 X2.25 Y0.0 R5.0 (Arc move of radius 5.0, endpoint at radius 2.25, angle 0°)

G01 X1.0 Y45.0 (Linear move to radius 1.0, angle 45°)

G15 (Disable polar coordinate mode)

G00 G53 Z0.0 (Z axis to machine zero)

M30 (Program end and rewind)

%

Figure 15-1: Tool path of polar coordinate mode example

G17/G18/G19: Plane Selection

Arcs, circles and drill cycles require the selection of a plane. The three axes X, Y and Z define three available planes XY, ZX, and YZ, see figure 17-1. The third axis defines the top of the plane, this axis is also known as the normal see figure 17-2. Selection of a plane is done by specifying one of three G-Codes: G17 for XY, G18 for ZX and G19 for YZ. These are modal G-Codes and will stay active until another plane is selected or the system is reset. The default plane selection is G17.

All arc and circular motion will take place on a single plane. Direction of motion, clockwise or counterclockwise, is as viewed from the normal direction, see figure 17-2.

Canned drill cycles also require the selection of a plane. In this case all hole positions will be located in the selected plane and the normal axis will be the drilling axis. For example in the XY plane the Z axis is the drilling axis.

Figure 17-1: Planes

Figure 17-2: Plane orientation

G20/G21: Unit Selection

Programming units are selected using G20 for inch and G21 for millimeter. Use these g-codes to specify the units in the program only; the setting will not affect position DROs, configuration settings, or offsets.

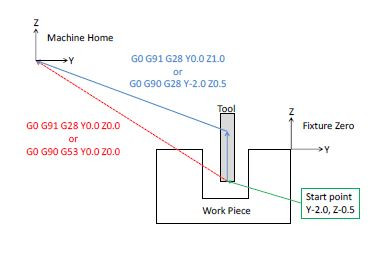

G28: Zero Return

This function is used to send one or more axes to the home position via an intermediate point. Exercise caution when using this function. If not fully understood the resulting motion may differ greatly from what is expected. When used correctly the intermediate point can be useful for avoiding obstacles in the way of a direct path to the home position, see figure 28-1.

Figure 28-1: Zero return via intermediate point

Format: G28 X_ Y_ Z_ A_ B_ C_

This is not a modal code and will only be active in the block in which it is specified. Following the G28 are the axes to be sent home. For example, to send the Z axis back to the home position program: G28 Z0. The value specified with the axis letter specifies the intermediate point.

Look at an example program:

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G00 X1.0 Y3.0 Z1.0 (Rapid to position)

G28 Z0.0 (Send Z axis home via point Z0)

M30 (Program end and rewind)

%

Reading through the program there is a safe start up block that sets the machine to absolute position mode. The next line causes the machine to move to the point X1, Y.5, Z1. in the coordinate system set by the G54 fixture offset. Now for the G28 block. This line of code, G28 Z0, gives instructions to send the Z axis to the home position via the point Z0. The motion will be as follows: First the Z axis will plunge to the point Z0 then return to home. If not intended this motion could result in a broken tool or scrapped part. To avoid this unintended motion the common programming format is as follows:

G91 G28 Z0In this case the intermediate point is an incremental move of 0 inches resulting in no motion before the Z axis returns home.

G30: 2nd, 3rd, 4th Zero Return

G30 functions the same way as G28, moving the machine to a zero return point via an intermediate point. However, instead of sending the machine to the home position, G30 movement ends at a user definable 2nd, 3rd, or 4th zero return point, specified by P2, P3, or P4 respectively. If P is omitted the 2nd zero return point is selected. This is handy for tool changers that are not located at the home position or any number of other applications.

Format: G30 P_ X_ Y_ Z_ A_ B_ C_

The 2nd zero return point is defined by # variables as follows:

| Axis | P2 #Variables | P3 #Variables | P4 #Variables |

| X | 5301 | 5311 | 5321 |

| Y | 5302 | 5312 | 5322 |

| Z | 5303 | 5313 | 5323 |

| A | 5304 | 5314 | 5324 |

| B | 5305 | 5315 | 5325 |

| C | 5306 | 5316 | 5326 |

The position values in the # variables can be set in a program or in MDI mode.

G31/G31.X: Probe function

Also known as skip function, G31 allows the use of part and tool probes. Multiple probes can be used, G31 for probe 1, G31.1 probe 2, G31.2 probe 3 and G31.3 probe 4. Motion is defined along linear axes, in a similar format to G01, with a feedrate.

Format: G31 X_ Y_ Z_ F_

The machine will move toward the specified end point, at the same time it is looking for the probe input to be activated. When the probe input is activated the current position is recorded to # variables according to the table below and motion is stopped. The recorded position can then be used to calculate tool offsets, work offsets, measure parts, etc.

| Axis | Part Position #Variables | Machine Position #Variables |

| X | 5061 | 5071 |

| Y | 5062 | 5072 |

| Z | 5063 | 5073 |

| A | 5064 | 5074 |

| B | 5065 | 5075 |

| C | 5066 | 5076 |

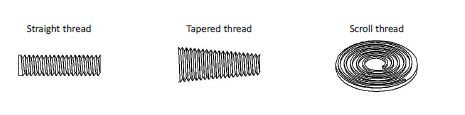

G32: Threading

It is possible to cut threads using a spindle to rotate the work piece and a non rotating threading tool. Equal lead straight, tapered and scroll threads can be cutting using this command.

Spindle speed feedback from an encoder, index pulse, tachometer or other device is required for this operation. The syncing of the feed axis to the spindle speed creates an accurate thread; however, axis acceleration can cause variations in the thread lead especially at the start and end of the thread. The compensate program a slightly longer thread to give the axis time to accelerate. The amount of extra thread length will vary based on machine specifications. Changes in spindle speed and feedrate will impact thread quality and accuracy. Using constant surface speed mode can also result in variations in thread lead when cutting tapered or scroll threads, use G97 constant RPM mode instead. During the threading move the spindle speed and feedrate overrides will be disabled and the machine will run at 100%. Feed hold will be delayed, if pressed the machine will stop at the end of the threading move.

Format: G32 X_ Y_ Z_ F_

The G32 threading cycle is a single linear move synced to the spindle speed. F specifies the lead or pitch of the thread. For example a 20 TPI thread would have a pitch of .05 inches, so program F.05. By default the movement is basic linear move with synced feedrate. Machine builders and advanced users have the added option to create custom M-Codes to specify the feed vector to create custom threads.

Example: Thread a ¼-20 rod held in the spindle, 1” length of thread.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G00 X0.3 Y0.0 Z0.1 (Rapid to position)

G97 M03 S1000 (Start spindle)

G00 X0.22 (Move to start position for rough pass)

G32 X0.22 Z-1.0 F0.05 (Cut straight thread)

G00 X0.3 (Retract X axis)

G00 Z0.1 (Return Z axis)

G00 X0.21 (Move to start position for finish pass)

G32 X0.21 Z-1.0 F0.05 (Cut straight thread)

G00 X0.3 (Retract X axis)

G00 Z0.1 (Return Z axis)

G00 G53 Z0.0 M5 (Return Z to home and stop spindle)

M30 (Program end and rewind)

%

Threads can also be cut with a taper by adding the proper end point. Example: Cut same thread as previous example with 0.03 taper.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G00 X0.3 Y0.0 Z0.1 (Rapid to position)

G97 M03 S1000 (Start spindle)

G00 X0.22 (Move to start position for rough pass)

G32 X0.25 Z-1.0 F0.05 (Cut straight thread)

G00 X0.3 (Retract X axis)

G00 Z0.1 (Return Z axis)

G00 X0.21 (Move to start position for finish pass)

G32 X0.24 Z-1.0 F0.05 (Cut straight thread)

G00 X0.3 (Retract X axis)

G00 Z0.1 (Return Z axis)

G00 G53 Z0.0 M5 (Return Z to home and stop spindle)

M30 (Program end and rewind)

%

Figure 32-1: Basic thread types

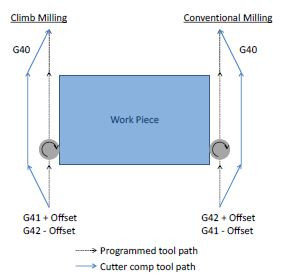

G40: Cutter Compensation Cancel

Cancels the cutter compensation mode. See also the Cutter Compensation portion of this manual.

G40.1: Arc Type Cutter Compensation

See also the Cutter Compensation portion of this manual.

-

This mode changes how the machine moves around corners when cutting.

-

When turned on, outside corners become rounded instead of sharp.

-

This rounding helps the machine move more smoothly at high speeds.

-

See figure 401-1 for an example (related to G40.1).

-

You can switch cutter compensation modes while the machine is running.

| G40.1: Arc type cutter compensation | G40.2: Line type cutter compensation |

Figure 401-1: Cutter compensation types.

Figure 401-2: G42 cutter compensation path.

G40.2: Line Offset Type Cutter Compensation

See also the Cutter Compensation portion of this manual.

This setting chooses a line offset cutter compensation mode. That means the machine tool automatically shifts the cutting path so the cutter cuts exactly where it should.

Here’s what it does:

-

External Corners: The tool moves in a square path around outside corners. (See figure 401-1, G40.2.)

-

Changing Modes: You can switch cutter compensation modes while the machine is running — you don’t have to stop the program. (See figure 401-2.)

This mode controls how the cutter path is adjusted and makes sure corners stay sharp and square.

G41/G42: Cutter Compensation Left/Right

See also the Cutter Compensation portion of this manual.

Cutter compensation lets the machine adjust the tool’s cutting path so the part is the correct size.

-

G41: Shifts the tool to the left of the programmed path.

-

G42: Shifts the tool to the right of the programmed path.

The amount of this shift comes from a tool offset chosen by D (this usually matches the tool’s radius).

-

If you include D, the machine uses that tool’s offset.

-

If you don’t include D, it uses the current tool’s radius instead.

There are two ways to call the offset value with G41 and G42.

Format 1: G00/G01 G41/G42 D_ X_ Y_ F_

Format 2: G00/G01 G41/G42 P_ X_ Y_ F_

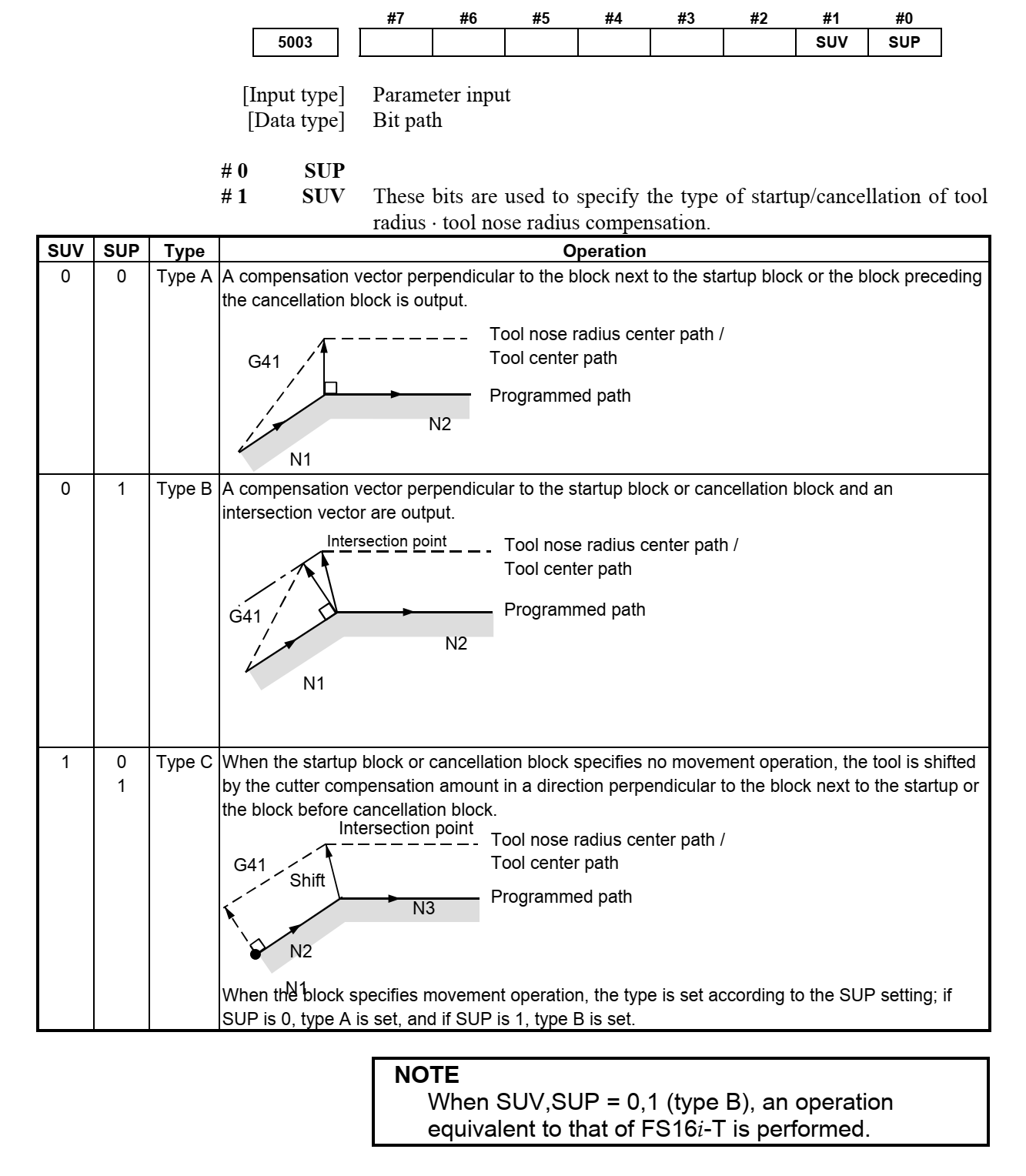

Mach 4 supports 3 types of Cutter Comp as of March 18 2025

- Type A: A compensation vector is a short move the CNC makes when starting or canceling cutter compensation.

-

This vector is always perpendicular (90°) to:

-

The block after the startup block (when turning compensation on)

-

The block before the cancellation block (when turning compensation off)

-

-

- Type B: A compensation vector is created at a 90° angle (perpendicular) to the startup or cancellation block.

-

An intersection vector is also created to connect the compensation move with the programmed tool path.

-

These vectors help the machine smoothly enter or exit cutter compensation.

-

- Type C: If a startup block (turning cutter comp on) or a cancellation block (turning it off) has no movement, the tool will still shift.

-

The tool shifts by the cutter compensation amount.

-

This shift happens in a direction perpendicular (90°) to:

-

The next block if it’s a startup block.

-

The previous block if it’s a cancellation block.

-

-

From FANUC-30i-63944EN_03-ProgManual.pdf, Appendix A Parameters, No. 4000-, page 2080 (The pdf file is attached at the top left of this document, below the export option.)

G43/G44: Tool Length Offset

Activates a tool length offset selected with H. When activated the position DROs will be updated to display the position of the program point of the tool, generally the tip. The tool offset can be applied in the positive direction with G43 or in the negative direction with G44. Generally G43 will be used to apply the tool offset. There are a number of ways of touching off a tool and determining the offset value, see tool offsets in the operation manual for more details, but they are all called and applied the same way.

Format: G43 H_ X_ Y_ Z_

If axis positions are specified in the same block as G43 the machine will move to the commanded point. If the axes are omitted there will be no motion.

G49: Tool Length Offset Cancel

Cancels the tool length offset. If no motion is commanded in the G49 block there will be no motion of the machine.

G50: Scaling Cancel

Cancels scaling.

G51: Scaling/Mirroring Function

When activated the scaling function multiplies all commanded positions by the specified scale factor. The DROs and offsets are not affected, but motion commanded from a program or the MDI screen is affected.

Format: G51 X_ Y_ Z_ A_ B_ C_

Specify the axis to be scaled and the desired scale factor. For example:

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G00 X4.0 Y0.0 Z1.0 (Rapid to position: X is at 4.0)

G51 X2.0 (Activate scaling 2x on X axis)

G00 X5.0 (Rapid to position: X is at 10.0)

G50 (Cancel scaling)

G00 X5.0 (Rapid to position: X is at 5.0)

M30 (Program end and rewind)

%

When scaling is active position moves will be calculated by multiplying the commanded position by the scale factor. In the example above the scale factor on the X axis is set to 2, then a move to X5. is commanded. The actual end position of this move will be 5 * 2 = 10. So the X axis moves to 10.

Exercise caution when using scaling, the results can be unpredictable depending on program complexity. For example if G52 X2 Y4 is programmed followed by an arc move in the XY plane, the arc will NOT be scaled 2x in the X axis and 4x in the Y axis to obtain an ellipse. The start and end positions will be as expected, but the motion from one to the other may not be. Check and double check the tool path display before running the program.

To mirror a program, enter a negative scale value. For example:

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G00 X4.0 Y0.0 Z1.0 (Rapid to position: X is at 4.0)

G51 X-1.0 (Activate scaling -1x on X axis)

G00 X5.0 (Rapid to position: X is at -5.0)

G50 (Cancel scaling)

G00 X5.0 (Rapid to position: X is at 5.0)

M30 (Program end and rewind)

%

G52: Local Coordinate System Shift

The local coordinate system setting is a programmable work shift. The setting is global; the entire system is shifted by the specified values. Every fixture offset will be affected, although the actual fixture offset values will not be changed.

Format: G52 X_ Y_ Z_ A_ B_ C_

To activate a local coordinate system with G52 use the above format. Setting of a local coordinate system is just like setting a fixture offset. In the G52 block specify the desired axes to set, and the value of the shift. For example (see figure 52-1 for the tool path):

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G00 X-4.0 Y0.0 Z1.0 (Rapid to position

M03 S2500 (Start spindle)

G12 I2.0 F30 (Cut circle with radius 2.0)

G52 X7.0 (Activate local coordinate shift with X axis offset of 7.0)

G00 X-4.0 Y0.0 Z1.0 (Rapid to same start point)

G12 I2.0 F30 (Cut identical circle)

G52 X0.0 (Cancel local coordinate shift on X axis)

M30 (Program end and rewind)

%

Figure 52-1: Example program tool path.

Once set, the setting will remain until cancelled by another G52 or the system is reset. As in the example above, a local coordinate system can be cancelled by specifying the axis with a value of zero. This effectively sets the local coordinate system shift to zero, giving it no effect.

G53: Machine Coordinate System

Although the majority of machine positioning will take place in a user created coordinate system it is sometimes beneficial to program positions in the machine coordinate system. G53 is a non modal, only active for the block in which it is specified, G-Code that allows the user to make positioning moves in the machine coordinate system. This can be useful for moving to a load/unload position at the end of a program or moving to a tool change location in a tool change macro. This is also a much safer way to move back to the machine home position, G53 X0 Y0 Z0, than using G28 as there is no intermediate position to be concerned with.

Format: G53 X Y Z A B C

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G00 X4.0 Y0.0 Z1.0 (Rapid to position in G54 coordinates)

G53 G00 Z0.0 (Rapid Z to home position)

G53 G00 X10.0 Y0.0 (Rapid to position in machine coordinates)

M30 (Program end and rewind)

%

In the example above, the last two positioning moves are made in the machine coordinate system. These two blocks could be the same for every program in this machine.

G54-G59: Fixture Offset

Used to select the active fixture offset in a program. The fixture offset will stay active until another is called or the system is reset. It is possible to use multiple fixture offsets in a single program.

G54.1: Additional Fixture Offsets

Additional fixture offsets are provided for users with many fixtures/parts/ setups. There are 248 additional offsets available.

Format: G54.1 P_

P specifies the number of the additional offset, 1 thru 248.

Previous version of Mach use G59 P7, P8 and so on. These legacy offsets can still be used in place of the G54.1. G59 P7 = G54.1 P1, G59 P8 = G54.1 P2, and so on. G54.1 is more consistent with industry machines.

Please see the fixture offset section of the Mach4 Mill Operations Guide for more detail on setting up fixture offsets.

G60: Unidirectional Approach

In cases where mechanical backlash causes positioning errors unidirectional approach can be used to increase accuracy. G60 is a non-modal code, when specified in a movement block motion will move to the end point from a parameter defined distance and direction, see figure 60-1. The distance and direction of the approach movement is specified by setting values in # variables as shown in the following table:

| Axis | #Variable |

| X | 5440 |

| Y | 5441 |

| Z | 5442 |

| A | 5443 |

| B | 5444 |

| C | 5445 |

Format: G60 G00/G01 X_ Y_ Z_

When unidirectional approach is used in a drill cycle the Z axis motion is not affected. G76 and G87 boring cycles have a tool shift that is also not affected by the G60 unidirectional approach.

Figure 60-1: Unidirectional approach.

G61: Exact Stop Mode

In exact stop mode the machine will decelerate to a complete stop at the end of each commanded move, see figure 9-1. This is a modal code, once activated it will remain on until canceled. For sharp corners and simple positioning this mode works well. However, when the code gets more complex, or in side milling with arcs, the exact stop mode will produce jerky motion and witness marks on the work piece. For most milling jobs use G64.

G64: Constant Velocity Mode

In constant velocity mode, the control will try to maintain feedrate even around sharp corners. As a result sharp corners will be slightly rounded and the machine may never reach the programmed point before a direction change. The magnitude of these position errors will be determined by the acceleration capability of the machine and the programmed feedrate. In most cases the error will be too small to notice or affect part function. Cutting will be faster and smoother with better finishes and no witness marks from stopping. This will be the active mode for the majority of machining time. It is modal and will be active until exact stop mode is activated.

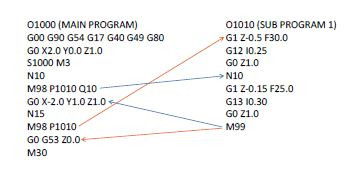

G65: Macro Call

Macros work like subprograms (see M98 on page 60) but allow values to be passed from the main program in the form of local variables. Macro programs can use these local variables passed to it to change part dimensions, select features, adjust feedrates, or anything else the user could need to change.

Format: G65 P_ A_ B_ C_ …

Warning! subroutines are sensitive to file name extensions, if you use one default to ".nc" ".txt" does not work.

The desired program number to be called is specified by P. The remaining arguments are determined by the macro program being called. The values of these arguments will be passed to local variables for use in the macro program. The available arguments and corresponding variables are shown in the table below.

| Address | Variable | Address | Variable | Address | Variable |

| A | #1 | I | #4 | T | #20 |

| B | #2 | J | #5 | U | #21 |

| C | #3 | K | #6 | V | #22 |

| D | #7 | M | #13 | W | #23 |

| E | #8 | Q | #17 | X | #24 |

| F | #9 | R | #18 | Y | #25 |

| H | #11 | S | #19 | Z | #26 |

The G65 macro call is non modal and has no option for repeating, the macro subprogram will be run only once per G65 call. For more information on macro programming and the availability and use of # variables see the Mach4 Macro Programming Guide.

G66: Modal Macro Call

Sometimes it is useful to run the same macro in different positions (similar to drilling canned cycles) or with different parameters. G66 is a modal macro call, the macro is called and values passed in the same way as G65, but G66 remains active until cancelled. The block(s) following the G66 can contain new positions and variables to run the macro again.

Format:

G66 P_ A_ B_ C_ …

A_ B_ C_ …

G67

More information on macro programming is available in the Mach4 Macro Programming Guide.

G67: Modal Macro Call Cancel

Cancels the macro modal call.

G68: Coordinate System Rotation

It is possible to rotate a program around a specified point using the coordinate system rotation command. It is specified as follows:

Format: G68 X_ Y_ R_

The command is only available in the XY (G17) plane and is modal. X and Y specify the point around which the program will be rotated, and R specifies the angle. A positive value for R will rotate the program counter clockwise when looking at the plane from the positive direction.

Once the rotation command is given, all command moves will take place in this rotated system. In effect, the X and Y axes of the machine will rotate the amount specified by R.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G00 X0.0 Y0.0 Z1.0 (Rapid to position)

G68 X0.0 Y0.0 R45.0 (Rotate 45° counter clockwise around X0, Y0)

G00 X1.0 (Rapid to position)

G69 (Cancel rotation)

M30 (Program end and rewind)

%

In the example above, the machine will move to X0, Y0 then initiate the coordinate rotation of 45°. The next move is a purely X axis move to X1. However, because the coordinate system has been rotated the current X axis is actually 45° from the machine actual X axis. When the move takes place both X and Y axes will move to the programmed point. In this case the DROs will read X.7071 and Y.7071. See figure 68-1.

Figure 68-1: Coordinate system rotation (G68 X0 Y0 R45)

The coordinates X.7071 and Y.7071 can be proven using simple geometry or trigonometry functions.

Coordinate system rotation is useful in many applications. Combined with a part probe the function can provide a lot of power and accuracy. When probing a part to find its location, it is also possible to determine if the part is clamped square to the axes or if it is oriented at some angle. If the part is skewed at an angle it can be automatically compensated for, resulting in higher quality parts.

G69: Coordinate System Rotation Cancel

Cancels a coordinate system rotation command. The machine returns back to normal function.

G73-G89: Canned Cycles

Canned cycles are special G-Codes used to simplify programming. See the Canned Cycles section of this manual for detailed information.

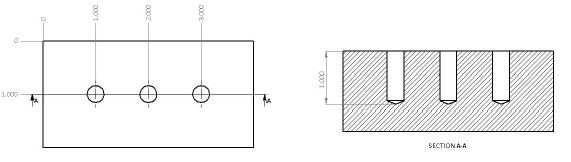

G90/G91: Absolute/Incremental Position Mode

In absolute position mode, the machine will move to the commanded position in the active user coordinate system.

Example: Write a program to move to the hole positions in figure 90-1 in absolute position mode. Assume the machine starts at position X0, Y0, end the program at X0, Y0.

Figure 90-1: Hole pattern example

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G90 (Absolute position mode)

G00 X1.0 Y-1.0 (Rapid to 1st hole)

G00 X2.0 (Rapid to 2nd hole)

G00 X3.0 (Rapid to 3rd hole)

G00 X0.0 Y0.0 (Rapid to origin point)

M30 (Program end and rewind)

%

In incremental position mode, commanded moves are interpreted as distance and direction from the current position. A command of X1 will move 1 in the positive direction, NOT necessarily to the point X1 in the user coordinate system.

Example: Write a program to move to the hole positions in figure 90-1 in incremental position mode. Assume the machine starts at position X0, Y0, end the program at X0, Y0.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G91 (Incremental position mode)

G00 X1.0 Y-1.0 (Rapid to 1st hole)

G00 X1.0 (Rapid to 2nd hole)

G00 X1.0 (Rapid to 3rd hole)

G00 X-3.0 Y1.0 (Rapid to origin point)

M30 (Program end and rewind)

%

Compare this to the program from G90. Because the starting point is X0, Y0 in both examples the move to the 1st hole is the same. However, if the machine started at X1, Y1 the absolute position program would still be correct, the incremental program would be shifted by the start location. For this reason it is important to ensure the proper mode is enabled for the program in use. A good safe start line will always contain a G90 or G91. These G-Codes are modal and will stay active until the other is specified.

G90.1/G91.1: Absolute/Incremental Arc Center Mode

This setting affects arcs when programmed in the I, J, K format. In absolute arc center mode the I, J, K values designate the position of the arc center in the user coordinate system. In incremental arc center mode the I, J, K values designate the distance and direction to the arc center from the start point. See figure 2-1 for a graphical description.

Figure 2-1: Path of tool point in circular and helical interpolation (G02).

Example: Program an arc centered at 1.0, 0.0 in the XY plane with radius 2. Start point at 3.0,0.0 and sweep 90 degrees counter clockwise. Program two times, once in incremental arc center mode and once in absolute arc center mode.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G91.1 (Incremental arc center mode)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X3.0 Y0.0 (Rapid XY to position)

G43 H1 Z0.5 (Activate tool offset #1 and move to Z rapid plane)

G01 Z0.0 F10 (Z plunge at feedrate)

G03 X1.0 Y2.0 I-2.0 J0.0 F10 (Arc move)

G00 Z0.5 (Retract Z to rapid plane)

G53 G00 Z0.0 (Return Z to home)

M30 (Program end and rewind)

%

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G90.1 (Absolute arc center mode)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X3.0 Y0.0 (Rapid XY to position)

G43 H1 Z0.5 (Activate tool offset #1 and move to Z rapid plane)

G01 Z0.0 F10 (Z plunge at feedrate)

G03 X1.0 Y2.0 I1.0 J0.0 F10 (Arc move)

G00 Z0.5 (Retract Z to rapid plane)

G53 G00 Z0.0 (Return Z to home)

M30 (Program end and rewind)

%

Notice the difference in the I values of the example programs. Both programs will produce the same arc.

G92: Local Coordinate System Setting

The coordinate system can be set by issuing G92 in the program. This function differs from G52 (Local Coordinate System Shift) in the way that it is specified. While G52 is specified with shift values, G92 is specified with the desired axis position. The affect is global and should be used with caution.

Format: G92 X_ Y_ Z_ A_ B_ C_

Using the above format specify a value for the desired axis. When G92 is specified the position DRO’s are updated to the values specified. The local coordinate system setting will be cancelled when a G92.1 is specified or the system is reset.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

G00 X4.0 Y0.0 Z1.0 (Rapid move; current position X4, Y0, Z1)

G92 X1.0 Y2.0 Z3.0 (Set local coordinate system; current position X1, Y2, Z3)

G92.1 (Cancel local coordinate system; current position X4, Y0, Z1)

M30 (Program end and rewind)

%

G92 was used for fixture offset setting before fixture offsets were available. It is recommended that the fixture offsets be used instead of using G92. The offset amount of the G92 setting is not immediately known by the user, because of this the results can be unpredictable when fixture offsets and G92 are combined.

G93: Inverse Time Feed

Inverse time feed is most commonly used for machine movement containing at least one rotary axis, however that is not the only application. Instead of specifying a velocity a time to complete the movement is specified. The following formula is used to determine F:

When inverse time feed is active an F word is required in every block of code containing a feed move.

G94: Feed Per Minute

Most common feedrate setting, where the operator specifies the desired feedrate in units/minute. In this mode the feedrate is modal and not required in all feed move blocks.

G95: Feed Per Revolution

In mills, the feed per revolution setting is most commonly used for tapping cycles. In this mode the feed rate is specified in units/revolution of the spindle. In the case of tapping the feedrate can be set as the pitch of the tap. For every revolution of the spindle the machine will move the specified units. Feed per rev mode requires RPM feedback from the spindle.

G96: Constant Surface Speed

Spindle speed can be specified two ways. One is constant surface speed. In this mode, the control will try to keep the surface speed constant based on cutting diameter. Surface speed is specified in surface units per minute. In the inch mode this is surface feet per minute, in millimeter mode it is surface meters per minute.

G97: Constant RPM

In this mode the spindle speed is specified in revolutions per minute. This is the most common setting for milling machines.

G98: Initial Point Return

Specifies that a canned cycle end at the initial Z level. The machine will also return to the initial point before a rapid move to the next position. Initial point return is useful for avoiding steps in parts or fixture clamps without adding a significant amount of cycle time. See figure 98-1.

Figure 98-1: Initial and R point return setting.

G99: R Point Return

Specifies that a canned cycle end at the programmed R level, see figure 98-1. When drilling holes in a flat plate, G99 can be used to reduce excessive machine movement decreasing cycle time.

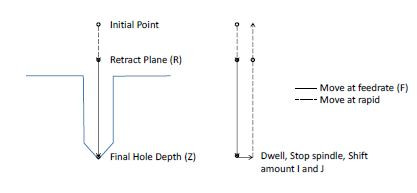

Canned Cycles

Canned cycles are used to reduce program complexity. For example peck drilling a 1 inch hole with .1 inch peck depth would use 30 lines of regular code, but with a canned cycle this same hole can be competed in just 2 lines of code. More importantly if multiple holes are required only 1 extra line of code per hole is needed. There are a variety of canned cycles for different hole types including drilling, boring, and tapping.

Hole machining cycles all behave similarly and mostly contain the same parameters. The meaning of each parameter can change depending on two settings. The first is the absolute or incremental mode setting (G90/G91) as defined earlier in this manual. The second is the return point selection G98 initial point return or G99 R point return.

Plane selection (G17/G18/G19) can also have an effect on hole machining cycles. Positioning will take place in the active plane, and the drilling operation will be on the normal axis. For example in G17 (XY Plane) hole position will be on the XY plane and the drilling axis will be Z. In G18 (ZX Plane) positioning will be on the ZX plane and the drilling axis will be Y. For the purposes of this manual all examples and definitions will be in the XY plane (G17).

The basic format of a canned cycle is as follows:

G98/99 X_ Y_ Z_ Q_ R_ P_ L_ F_

X_ Y_

G80

The X and Y coordinates on each following line before the G80 will repeat the same canned cycle at the new position. Those positions can be incremental or absolute. Note that not all arguments will appear in all cycles, and there are a couple special cases that will be discussed.

| C | Number of the desired canned cycle (i.e. 81, 83, 74, etc) |

| X | In G90: X position of the center point of the first hole with respect to the current work zero point |

| In G91: Distance and direction along X axis to center point of first hole from the current position | |

| Y | In G90: Y position of the center point of the first hole with respect to the current work zero point |

| In G91: Distance and direction along Y axis to center point of first hole from the current position | |

| Z | In G90: Z position of bottom of hole with respect to the current work zero point |

| In G91: Distance and direction along Z axis, from point R, to bottom of hole | |

| Q | Peck increment if deep hole drilling, always positive |

| R | Retract plane, retract position between pecks, in G99 mode this is the rapid plane |

| P | Dwell, in milliseconds, at bottom of hole |

| L | Number of repetitions |

| F | Feedrate |

Figure 2: Example hole pattern

G73: High Speed Peck

In materials that produce long stringy chips a high speed peck cycle can be used to break them up. Unlike the G83 cycle that retracts completely out of the hole after each peck, the G73 cycle only retracts .100 inch. See figure 73-1. This short retract helps to reduce cycle times when a complete retract is unnecessary.

Format: G73 X_ Y_ Z_ Q_ R_ L_ F_

- X, Y: Position of hole in XY plane

- Z: End point of hole

- Q: Peck amount

- R: Retract plane

- L: Number of repetitions

- F: Feedrate

Figure 73-1: Motion of tool point for G73 cycle. End Z position will be determined by G98/99 setting.

Example: Create the program for the holes shown in figure 2 using a .025 peck depth.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G73 G99 X1.0 Y-1.0 Z-1.0 Q0.1 R0.25 F10 (Peck drill cycle start)

X2.0 Y-1.0 (Drill second hole)

X3.0 Y-1.0 (Drill third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%

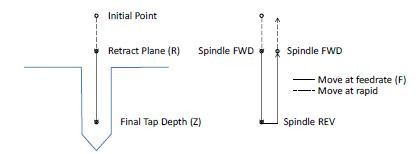

G74: Left Hand Tapping

Left hand tapping is the same as right hand tapping (G84) except that it will cut left hand threads. The spindle must be started in the reverse direction before calling the G74 cycle.

G76: Fine Boring

The fine boring cycle allows the user to stop the spindle and move the tool away from the wall before retracting. This allows for a rapid retract without leaving a scratch on the wall.

Format 1: G76 X_ Y_ Z_ R_ I_ J_ P_ L_ F_

Format 2: G76 X_ Y_ Z_ R_ Q_ P_ L_ F_

- X, Y: Position of hole in XY plane

- Z: End point of hole

- R: Retract plane

- I: X shift distance and direction

- J: Y shift distance and direction

- Q: Shift distance (Always positive. Direction and axis are defined by bits 5 and 4 in parameter 5101)

- P: Dwell in milliseconds

- L: Number of repetitions

- F: Feedrate

Note that the I, and J amounts will apply to the axes in your active plane. X and Y for G17, X and Z for G18, Y and Z for G19,

Figure 76-1: Motion of tool point for G76 cycle. End Z position will be determined by G98/99 setting.

After feeding to the bottom of the hole, the machine with pause for the specified dwell time, then the spindle will stop in the orient position before making the shift move defined by I and J. In machines with a spindle orient function called by M19 this will all be automatic. However, many machines are not capable of orienting the spindle so the orientation must be done manually.

This will allow the operator to manually orient the spindle before the shift move is made. Here is an example of the spindleorient.mcs macro for the manual orient:

Example: Create the program to fine bore the holes shown in figure 2.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G76 G99 X1.0 Y-1.0 Z-1.0 R0.25 I-0.025 J0 F10 (Fine bore cycle, shift X-0.025 at bottom)

X2.0 Y-1.0 (Drill second hole)

X3.0 Y-1.0 (Drill third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%

G80: Canned Cycle Cancel

To end a canned cycle a G80 must be called. G80 should be specified on its own line to avoid any unintended movements.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G81 G99 X1.0 Y-1.0 Z-1.0 R0.25 F10 (Drill cycle start)

X2.0 Y-1.0 (Drill second hole)

X3.0 Y-1.0 (Drill third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%

G81: Drilling

This is a straight drilling cycle. The tool simply moves to position, feeds to the bottom of the hole then rapid retracts to either the R point or the initial point. See figure 81-1 for a graphic of the tool motion. The format is as follows:

Format: G81 X_ Y_ Z_ R_ L_ F_

- X, Y: Position of hole in XY plane

- Z: End point of hole

- R: Retract plane

- L: Number of repetitions

- F: Feedrate

Figure 81-1: Motion of tool point for G81 cycle. End Z position will be determined by G98/99 setting.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G81 G99 X1.0 Y-1.0 Z-1.0 R0.25 F10 (Drill cycle start)

X2.0 Y-1.0 (Drill second hole)

X3.0 Y-1.0 (Drill third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%

G82: Spot Face

Spot face adds the ability to dwell at the bottom of the hole for a specified amount of time. The actual tool motion is the same as a G81 cycle, however with the dwell it is possible to attain better accuracy and finish at the bottom of the hole. This is useful for chamfering, counter boring, and spot facing. The format is as follows:

Format: G82 X_ Y_ Z_ R_ P_ L_ F_

- X, Y: Position of hole in XY plane

- Z: End point of hole

- R: Retract plane

- P: Dwell

- L: Number of repetitions

- F: Feedrate

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G82 G99 X1.0 Y-1.0 Z-0.2 P0.2 R0.25 F10 (Spot drill cycle start)

X2.0 Y-1.0 (Drill second hole)

X3.0 Y-1.0 (Drill third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%

G83: Peck Drilling

Peck drilling is a cycle used for drilling deep holes. The cycle allows for breaking and clearing of chips and better application of coolant by fully retracting the tool from the hole between pecks. This retract move and plunge to previous depth are rapid moves, each peck is a feed move at the specified feed rate. See figure 83-1 for a graphic of the tool motion. The format is as follows:

Format: G83 X_ Y_ Z_ Q_ R_ L_ F_

- X, Y: Position of hole in XY plane

- Z: End point of hole

- Q: Peck amount

- R: Retract plane

- L: Number of repetitions

- F: Feedrate

Figure 83-1: Motion of tool point for G83 cycle. End Z position will be determined by G98/99 setting.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G83 G99 X1.0 Y-1.0 Z-1.0 Q0.1 R0.25 F10 (Peck drill cycle start)

X2.0 Y-1.0 (Drill second hole)

X3.0 Y-1.0 (Drill third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%

G84: Right Hand Tapping

The tapping cycle is used to create threaded holes using a tap. Tapping requires that the spindle rpm and Z axis feedrate be matched, related by the pitch of the thread being cut. There are two ways to achieve this synchronization of spindle speed and Z axis feedrate. From the programming side it is easier to program the feedrate in units per revolution (G95). In the feed per rev mode the commanded feedrate will be simply the pitch of the thread. Metric threads are classified with the thread pitch, i.e. M8x1.25mm thread has a 1.25mm pitch. Unified threads are classified by threads per inch which requires a bit of calculation to get the pitch, don’t worry it’s easy. Simply divide 1 inch by the TPI. For a ¼-20 fastener we would calculate 1/20 = .05, this is the pitch. The catch is, to use feed per rev requires some form of rpm feedback from the machine, not every machine will have this. For the machines without feedback the tapping cycle can be programmed in feed per min mode (G94). This method requires a little more math to obtain the correct feedrate based on spindle rpm and pitch of the thread. The equation looks like this: RPM*Pitch=IPM. To tap that ¼-20 hole at 1500 RPM we first need to calculate the pitch, remember 1/TPI = Pitch, so 1/20=.05. Now we calculate the feed per min as 1500 * .05=75 IPM. It is important to note that if the spindle speed is changed, the feed per minute must also be changed to match. Now that the math is done, check out the format of the code:

Format: G84 X_ Y_ Z_ R_ L_ F_

- X, Y: Position of hole in XY plane

- Z: End point of hole

- R: Retract plane

- L: Number of repetitions

- F: Feedrate

The motion of the tapping cycle is straight forward, but does require some additional description. See Figure 84-1 for a graphic of the tool motion. The movement is very similar to a straight drill cycle, action of the spindle being the major difference. The spindle must be started in the forward direction prior to calling the G84 cycle. The machine will then move to the hole position then the Z axis will move down to the R plane. The Z will feed down to the specified depth then the spindle and Z axis will stop then reverse direction to retract out of the hole. Due to slight variations of spindle speed, feedrate and accelerations in some machines it is recommended that a special tapping head be used. A tapping head allows the tap to float a little bit, compensating for those variations, especially at the bottom of the hole.

Changes to feedrate or spindle speed mid cycle can be damaging to the tool and work piece, for this reason the feedrate and spindle speed overrides are disabled. The machine will run at 100% override for the duration of the cycle. Feed hold is also disabled during the cycle. If feed hold is pressed motion will stop at the end of the tapping cycle.

Figure 84-1: Motion of tool point for G84 cycle. End Z position will be determined by G98/99 setting.

You can change the wait time before the Z retracts by changing a Control Parameter 1805 to 1. This will wait till the spindle is up to speed before allowing the Z to reverse. If 1805 is set to 0, it will immediately start retracting the Z when it reaches the bottom of the hole.

Example:

Create the program to tap the holes shown in figure 2 to a depth of .500 with a 3/8-16 tap using feed/min.

1/16=.0625

1000*.0625=62.5

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S1000 (Start spindle)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G84 G99 X1.0 Y-1.0 Z-0.5 R0.25 F62.5 (Tapping cycle start)

X2.0 Y-1.0 (Tap second hole)

X3.0 Y-1.0 (Tap third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%

G84.2/G84.3: Right and Left Hand Rigid Tapping

Rigid tapping can be performed on capable machines. As the name implies the tap is held rigidly in the spindle, no tension/compression style tapping holder is required. Holding the tap in this manner requires the machine to have precise control of spindle speed, axis feed, and precise feedback of spindle RPM. The tapping axis will be electronically geared to the spindle RPM. Use G84.2 for right hand tapping and G84.3 for left hand tapping. See figure 84-1 for a graphic of the motion.

Format: G84.2/84.3 X_ Y_ Z_ R_ P_ L_ F_ J_

- X, Y: Position of hole in XY plane

- Z: End point of hole

- R: Retract plane

- P: Dwell in milliseconds

- L: Number of repetitions

- F: Feedrate

- J: Spindle speed for retract

As will other tapping cycles the feedrate and spindle speed overrides are disabled and set to 100% for the duration of the cycle. Feed hold is also no effective until the end of the tapping cycle.

Example:

Create the program to tap the holes shown in figure 2 to a depth of .500 with a 3/8-16 tap using feed/min. Tap at 1000 RPM, retract at 2000 RPM

1/16=.0625

1000*.0625=62.5

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S1000 (Start spindle)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G84.2 G99 X1.0 Y-1.0 Z-0.5 R0.25 F62.5 J2000 (Tapping cycle start)

X2.0 Y-1.0 (Tap second hole)

X3.0 Y-1.0 (Tap third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%

G85: Boring, Feedrate Retract

G85 is a straight boring cycle, most commonly used for boring or reaming. The retract is at the programmed feedrate with the spindle on.

Format: G85 X_ Y_ Z_ R_ L_ F_

- X, Y: Position of hole in XY plane

- Z: End point of hole

- R: Retract plane

- L: Number of repetitions

- F: Feedrate

Figure 85-1: Motion of tool point for G85 cycle. End Z position will be determined by G98/99 setting.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G85 G99 X1.0 Y-1.0 Z-1.0 R0.25 F10 (Peck drill cycle start)

X2.0 Y-1.0 (Drill second hole)

X3.0 Y-1.0 (Drill third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%

G86: Boring, Rapid Retract

G86 is a straight boring cycle. Before retracting from the hole the spindle is stopped. The retract is then performed at the rapid rate. This will leave a scratch or multiple scratches where the cutting edges are in contact with the wall.

Format: G86 X_ Y_ Z_ R_ P_ L_ F_

- X, Y: Position of hole in XY plane

- Z: End point of hole

- R: Retract plane

- P: Dwell in milliseconds

- L: Number of repetitions

- F: Feedrate

Figure 86-1: Motion of tool point for G86 cycle. End Z position will be determined by G98/99 setting.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G86 G99 X1.0 Y-1.0 Z-1.0 R0.25 F10 (Boring cycle start)

X2.0 Y-1.0 (Bore second hole)

X3.0 Y-1.0 (Bore third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%

G87: Back Boring

G87 is a back boring cycle. This is a useful cycle for spot facing, counter boring or chamfering the back side of a part. At the start of the cycle the spindle will be stopped at the orient position and the tool offset from the hole center by the distance and direction defined by I and J. For machines that do not have the ability to orient the spindle, see the M19 macro example in the G76 cycle description. The tool can then be positioned to the R point below the work piece. Once at the R point the tool will be positioned at the hole center and the spindle started to perform the back boring operation. When the specified Z point is reached the machine will orient the spindle, offset by amount I, J and retract back to the initial point. In this cycle the R point will always be below the work piece, not a good point the end the cycle. For that reason this canned cycled will always return to the initial point, it is not possible to specify a G99 R point return.

Format 1: G87 X_ Y_ Z_ R_ I_ J_ P_ L_ F_

Format 2: G87 X_ Y_ Z_ R_ Q_ P_ L_ F_

- X, Y: Position of hole in XY plane

- Z: End point of hole

- R: Retract plane

- I: X shift distance and direction

- J: Y shift distance and direction

- Q: Shift distance (Always positive. Direction and axis are defined by bits 5 and 4 in parameter 5101)

- P: Dwell in milliseconds

- L: Number of repetitions

- F: Feedrate

Figure 87-1: Motion of tool point for G87 cycle. End Z position will be determined by G98/99 setting.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G87 G99 X1.0 Y-1.0 Z-0.85 R-1.05 I-0.1 F10 (Back boring cycle start, shift -0.1 in X axis)

X2.0 Y-1.0 (Bore second hole)

X3.0 Y-1.0 (Bore third hole)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%

G88: Boring, Manual Retract

This boring cycle features a manual retract. At the bottom of the hole the specified dwell is performed, then the spindle is stopped and the program paused. The operator can then manually retract the tool from the hole. After retracting the tool cycle start is pressed to continue program operation.

Format: G88 X_ Y_ Z_ R_ P_ L_ F_

- X, Y: Position of hole in XY plane

- Z: End point of hole

- R: Retract plane

- P: Dwell in milliseconds

- L: Number of repetitions

- F: Feedrate

Figure 88-1: Motion of tool point for G85 cycle.

G00 G90 G54 G17 G40 G49 G80 (Safe start line)

M06 T01 (Tool change)

M03 S2500 (Start spindle)

G00 X1.0 Y-1.0 (Rapid to XY position)

G43 H1 Z0.5 (Activate tool offset 1 and move to Z initial point)

G88 G99 X1.0 Y-1.0 Z-1.0 R0.25 F10 (Boring cycle start, pause for manual retract)

X2.0 Y-1.0 (Bore second hole, pause for manual retract)

X3.0 Y-1.0 (Bore third hole, pause for manual retract)

G80 (Canned cycle cancel)

G53 G00 Z0 (Return Z to home)

M30 (Program end and rewind)

%

G89: Boring, Dwell & Feedrate Retract

Same function as G85 with the addition of a dwell at the bottom of the hole.

Format: G89 X_ Y_ Z_ R_ P_ L_ F_

- X, Y: Position of hole in XY plane

- Z: End point of hole

- R: Retract plane