SOURCE Tool Setters and Offsets

Open the Calibrate Tool Setters window. Found on the Tools tab.

Creating a Manual Tool Setter

Mapping the input to a software signal

Pull down Configure -> Control and select the Input Signals tab.

Some signals are pre-configured when MachPro is installed.

Tool Setter Limit (Over Travel) maybe be mapped to Input #6

Tool Setter Input may be mapped to Probe1.

-

In the Tool Setter tab, click Add New to create a new tool setter.

-

Enter a unique name for the tool setter.

-

Select the new tool setter from the list to display its settings on the right side.

1. Setter Type

-

Under Setter Type, select Manual.

2. Tool Setter Height

-

Measure the physical height of the tool setter.

-

Enter the measured value in the Tool Setter Height field.

3. Z Position

-

For a fixed-mounted setter:

-

Use the Z Position Wizard to determine the machine coordinate for the top surface of the setter.

-

Once set correctly, this value should not be changed.

-

-

If the setter is mounted outside the soft limits, enable Disable Softlimits.

- Once the Z position and height are calibrated, the system will automatically use these values for all tool length offset calculations.

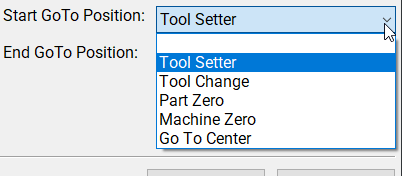

4. GoTo Position (Optional)

-

Define a GoTo Position so the spindle can safely move to the tool setter before touch-off.

-

This ensures a consistent and safe approach, reducing the risk of collisions.

Randomly placed tool setter

-

Set Initial Parameters

-

Set the Z Position to 0.0.

-

Leave all GoTo fields blank.

-

This indicates that the setter position may change between uses.

-

-

Prepare the Spindle

-

Remove all tools from the spindle.

-

If the spindle uses tool holders or collets, insert an empty holder while setting the Z position.

-

-

Position the Tool Setter

-

Place the manual tool setter or gauge blocks on the table at the desired location.

-

-

Set the Z Position

-

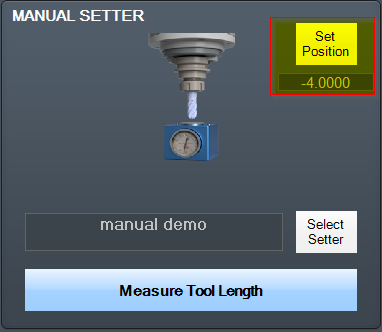

Carefully jog the spindle down until the tool tip touches the surface of the setter.

-

Click Set Position.

-

This records the Z position using the current spindle location and the entered Tool Setter Height value.

-

-

Measure Tools

-

Insert each tool required for the job.

-

Perform a tool measurement cycle for each tool to record its length offset.

-

Creating an Auto Tool Setter

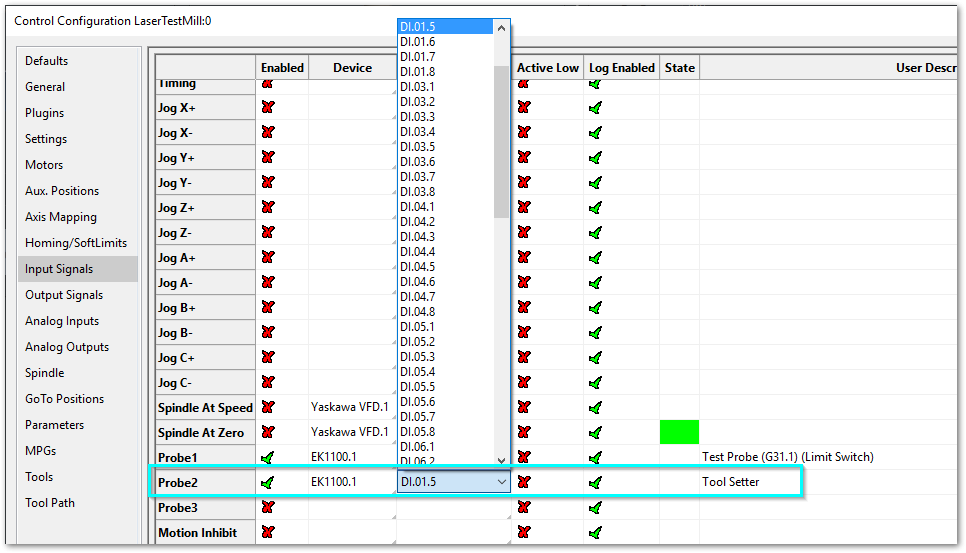

Pull down Configure -> Control and select the Input Signals tab

There may be partially configured signals for the tool setter:

- Tool Setter Limit (Over Travel)

- Tool Setter Input

Tool Setter Input Mapping

The signal for the tool setter input needs to be one of four signals.

- Probe (G31)

- Probe1 (G31.1)

- Probe2 (G31.2)

- Probe3 (G31.3)

Select an available input probe signal and map it to your motion control device - using the inputs you previously wired. In the example below, Probe2 (G31.2) is mapped to EK1100.1 DI0.1.5

When you installed MachPro with your motion controller, the motion controller plugin added all of your I/O ports to the device and inputs options for signal mapping.

In this example, the I/O device is a Beckhoff EK1100. The inputs are all DI (Digital Inputs) and the slices and ports are numbered. The plugin will create a similar numbering system for your motion controller's inputs.

Note the State column. This will tell you the current status of each mapped input, and can be used to verify your inputs.

Verify that input triggers properly when the tool setter is pressed. The State block will turn green. Toggle the Active Low field so that the signal is only active when the tool setter is pressed.

Tool Setter Limit (Over Travel) Input Mapping

Select an available input signal for Over Travel, and map it to your motion control device - using the inputs you previously wired.

Verify that input triggers properly when the tool setter is pressed down all the way - to an over travel condition. Adjust the Active Low field so that the signal is only active when the tool setter is pressed to an over travel condition.

Global Monitoring System (GMS) Adjustments

Pull down Configure -> Plugins -> Global Monitoring System

Go to the GMS settings and adjust that the Tool Setter Limit monitor to match your over travel input. See the GMS bookstack for details.

|

|

|

-

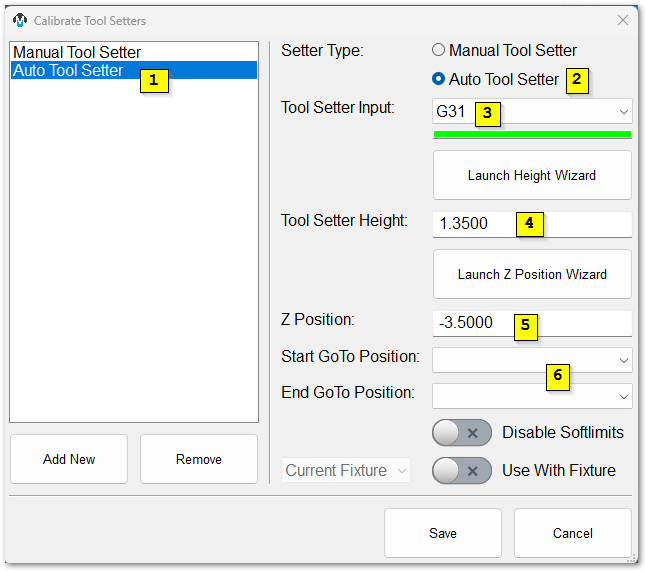

Click Add New to create a new tool setter.

-

Enter an appropriate name for the tool setter.

-

-

Set the Setter Type to Auto.

-

Select the Probe Input that the tool setter is wired to.

-

The indicator bar below the input selector will turn green when the tool setter is triggered.

-

Manually trigger the setter (or have a helper do so) to confirm the correct input is selected.

-

-

If the tool setter height is known, enter the value in the Tool Setter Height field.

-

If the height is unknown, click Launch Height Wizard and follow the on-screen instructions to measure it.

-

The tool setter must be wired to the control for this process.

-

-

Set the Z Position to the machine coordinate of the surface where the tool setter rests.

-

If the position is unknown, use the Z Position Wizard to determine it.

-

For a randomly placed setter, set the Z Position to 0.0. This value will be defined each time before measuring tools.

-

See also: Using a Randomly Placed Tool Setter.

-

-

(Optional) Define GoTo Positions for the tool setter.

-

Selecting a GoTo position allows the spindle to move automatically to the setter before touching off.

-

This is recommended for permanently mounted setters.

-

If the setter is located outside the soft limits, enable Disable Softlimits.

-

-

For randomly placed setters, leave all GoTo Position fields blank.

-

Manually jog the spindle to the setter or place the setter beneath the spindle as needed.

-

The machine will not perform automatic jogging during this process.

-

Align Tool Edge to Center of Tool Setter

This feature positions the edge of the tool precisely at the center of the tool setter, ensuring accurate alignment and consistent measurement results.

Pull down Configure -> Control and select the Settings Tab. Scroll down to the Measurements and Offsets section.

-

Set Tool Setter Align Tool Edge To Setter to Yes.

-

Configure the Tool Setter Align Tool Edge Offset parameter.

-

Choose between Tool Radius or Tool Setter Offset as the source for the offset used to align the tool edge to the center of the setter.

-

-

Select whether to Align (X or Y) Axis to Setter to define which way the tool moves when aligning the edge to the center of the setter.

- Close the Settings menu

- If you selected Tool Setter Offset, then open the Tool Table and click the Edit option

- Select the User Fields tab

- Select the Tool Setter Offset field, and use the movement buttons to place the field where you want within the User Fields

- Close the Tool Table Editor

- Select View and select User Fields

Additional Settings

The measuring and offsets settings in MachPro Control may provide helpful access to these settings. Pull down Configure -> Control and select the Settings Tab and scroll down to the Measuring and Offsets portion.

Modifying GoTo Positions

If you are setting up the GoTo position for a tool setter, jog the tool to the correct position over the tool setter.

Position Setup Instructions

-

Use the Add or Remove buttons at the bottom to manage positions.

-

When adding a new position, choose Machine Coordinates or Part Coordinates at the top.

-

To change an existing position, select it and edit as needed.

-

Each position builds a movement list in the Data Box. Use Delete to remove a movement.

- To add a custom G-code line, write it and click Add to include it in the Goto list.

⚠️ Do not use M Codes here.

This helps move the tool safely before other operations.

Add Movement Instructions

-

Click Include for each axis you want to move.

-

Click Get Current Position to copy the current coordinates, or type the coordinates manually.

-

Click Add/Update to save the movement in the Data Section.

Example: Z-Axis Movement

-

Define the Z-axis movement to run first.

-

Click Add/Update to insert this movement into the Data Box.

-

Add more actions in the next rows.

-

Optionally, add a final Z Rapid Move to bring the tool close to the setter.

I modified the Tool Setter position. Coordinate lines in the Data box will be in Machine Coordinates. This will be used as the Tool Setter position and can be called using the P2 variable.