Alexsys V4 Turn Operator Manual

Overview

ALEXSYS is a programming system for CNC machining centers. That combines features of CAD / CAM systems with typical features of conversational programming.

It is not necessary to be experienced with CAD/CAM systems to use this software.

The lathe module support all the most common turning operations.

- Face Turning

- External / Internal Turning

- External / Internal / Face Grooving

- Central Drilling

- External / Internal Threading , also tapered threads

- Cut-Off

Face Turning

Diameter Mode - Auto : Start and end diameter value are defined by stock dimension

Diameter Mode - Manual Values : Start and end diameter value are defined manually

Start Z : Reference Z , usually it's always 0

Corner Mode : Choose between chamfer or fillet

Init Chamfer : It the chamfer/fillet value.

Child operations:

1) Roughing Operation

Material to remove : Is the material width to remove , measure from Start Z to Z+ direction

Finishing allowance : Is the material width left to finishing operation by the roughing operation

2) Finishing Operation

No options for this operation.

Generic Turning

External Cycle : The tool moves from the outside the inner part of the component.

Internal cycle : The tool moves from the inner part of the component to outside.

Before proceed with internal cycle is necessary create a central hole in the component.

In important also use a tool with dimension compatible with this hole diameter.

You can find this information in tool catalog.

To add this operation, from [MENU] -> Lathe -> External or Internal Turning , depending on your needs.

Here the screen related to external / internal turning machining.

Geometry Selection

Generic turning accept as geometry both open profiles and closed profiles.

It's suggested to link just a single profile in geometry list.

Open Profile:

Closed Profile:

Turning Parameters

Turning direction - Traditional : Tool direction it's from Z+ to Z-

Turning direction - Reverse : Tool direction it's from Z- to Z+ , you need to select a compatible tool when you change this property.

Profile Start/End Extension : A tangent extension will be added to start/end of selected geometries

Apply Fillet on sharp corner : Where applicable, a fillet will be created in sharp corner.

Toolpath Limit : With this you can define the limits of working area.

Without Limit :

With Limit :

Operation 1 of 2 : Roughing

Finish Allowance X / Z : It's the material thickness left by the roughing tool for the finishing operation.

Roughing Macro : Where applicable , it will print G71 macro code in output code instead of simple movements

Finish with same tool : Finishing allowance material will be removed by the roughing tool

Operation 2 of 2 : Finishing

Reverse direction on vertical wall : When enable , the turning direction will be inverted in 90° profile element. In some context , this may reduce tool vibration.

Vertical wall threshold : Will be considered only elements with length bigger than this value.

Multiple finishing passes : It create multiple finishing passes. The distance between passes is determined by finishing allowance thickness.

example : If you have a 0.3mm of finish allowance and 3 finish passes. Toolpath will generate 3 passes with a 0.1mm distance between them.

Lathe Central Drilling

To add a drilling machining , from Menu -> Lathe -> Central Drilling

This is the machining property screen.

Here you can enable these sub-operations :

- Center Drill

- Drill

- Chamfer

- Tap

- Reamer

You can change the sub operation order manually from treeview. See related link at the bottom of this article.

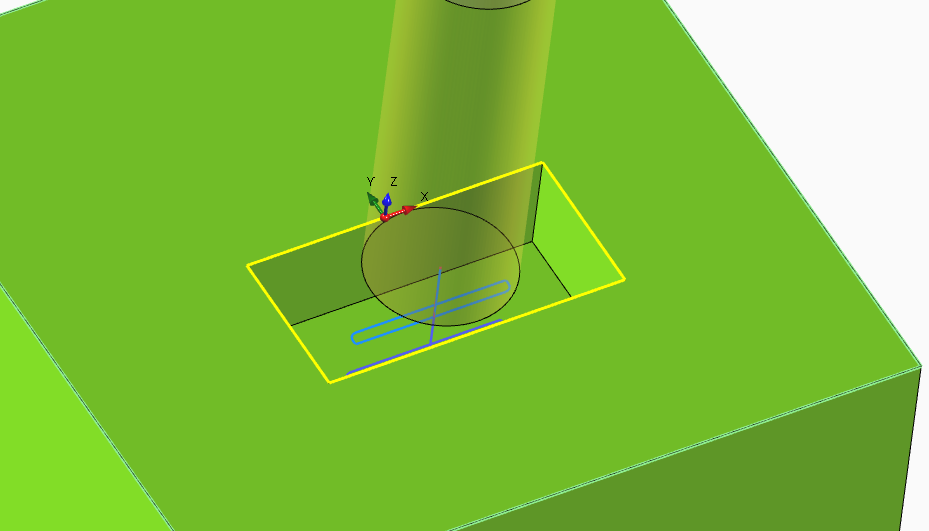

When a drilling operation is selected, is possible see also "ghost tool model" at the minimum reached z.

This is useful to check the tool path correctness at glance.

Safe Z : It's the Z Level of approach . The tool arrives at this level in rapid.

Start Z : This is the effective start working level. Usually it's 0

[Drill Operation] Add Drill Tip Length : It calculate the drill tool tip length and add it to inserted depth.

The drill tip length is calculated by tool diameter and tool angle. You can edit this properties from tool edit screen. See related link below.

[Chamfer] Define Chamfer Diameter : In chamfer operation is possible define the plain tool depth to execute or desired chamfer outer diameter.

If you select to define the outer chamfer diameter, the effective tool depth will calculated automatically based on selected chamfer tool geometry.

Lathe Threading

To add an threading machining operation , from MENU -> LATHE -> select EXTERNAL or INTERNAL Threading.

In the screen below you can see requested parameter.

You can pick thread default data by selecting a thread category and then selecting desired thread row from the drop down property.

After selecting desired thread, all related field are filled with default data from thread table.

To open thread table window , you can click on button indicated in following image, or from MENU->EDIT-> THREAD TABLE

Lathe cut-off operation

When is necessary cut away turned part from bar, you need the Cut operation .

Pick Point : Let you select outer diameter and Length with mouse cursor.

Outer Diameter : It's the start diameter of cut cycle

End Diameter : It's the end diameter of cut cycle. This diameter is compensated with tool nose radius in gcode.

Length: It's the desired length of part.

Chamfer : You can create a chamfer or fillet in cut corner.

Chip Breaking Movement : When enabled, it create a chip breaking movement instead of a plain work movement to cut the part. This help to create smaller chip.

Appendix

Import 2D CAD File

Import DXF/DWG

- You can't import 3D shape

- It's better clean the cad file , leaving only the needed geometry before importing the file.

With Alexsys you can import 2D geometries from DXF / DWG files.

-

First select the plane you want to import the geometries you can select the XY or the XZ planes.

The XZ is the lathe plane.

-

From menu [FILE] -> [OPEN FILE]

Choose the file you want to import.

How to generate G-Code

To Generate G-Code , press this button from main Menu or press F8 from keyboard.

-

This window dialog is the next step , here you can define gcode output filepath.

Press G-Code or keyboard [ENTER] to generate GCode.

After generation the generated machine code will be opened into select text editor.

If may receive this error message :

This means that some operations toolpath are not valid.

Look at tree view you have some operation with error icon.

Hover with mouse cursor the error icon to read message error.You need to solve all the issue before call g-code generation.

Hover with mouse cursor the error icon to read message error.You need to solve all the issue before call g-code generation.

Cad Editor

Alexsys is not indented to be a full CAD system, but with the available tools is possible draw basic profiles or do some little edits to imported geometries.

Toolpath Simulation

Is possible get the simulation of generated toolpath with the command "Simulation"

Here the simulation side screen.

With simulation control you can single-step forward or backward.

Pause and continue simulation

With this control you can increment simulation speed. Drag the cursor with mouse

This slider stand for the current operation timeline, you can drag the cursor forward or backward.

Tool Mode : is possible show the tool with transparency or hide it completely

Continue with next operation : If checked, at the end of an operation simulation, the next operation is played. Otherwise the animation is stopped. Use the 2 button to go to next or previous operation manually.

Show complete toolpath : If checked, all the movements of current operation are shown .By default , just a the last part of the toolpath is visualized . The length of this visualized toolpath is determined by the property "Toolpath length".

Stock Simulation : If checked, the material removal simulation is shown. This option might impact on performance.

Stop on Collision : When a rapid collision is detected, the animation is paused on collision event. This option , is enabled only when the stock simulation is active.

Information : Current tool position and cut data parameter are visible in the lower part of the screen.

To get better performance on a PC with limited hardware you can :

- Disable [Stock Simulation] . Only movements are showed

- Enable [Skip Intermediate Position] . Only movements endpoints are visualized

It's not detected any collision between tool and fixture or tailstock.

Also very high feed work movements into stock are not detected.

Only rapid movements into stock are detected as collision.Basic Concepts

Here a brief explanation to understand the workflow to convert toolpath into gcode.

NC Program stages

You can consider the nc-program as a sequence of stages , each stage has it's own template :

- G-Code Header

- For each operation

- Tool Change

- Tool Approach

- List of movements that make up the toolpath, or in some cases macros (drilling, tapping, etc ..)

- Tool disengagement

- Operation Finalization

- G-Code Footer

For each of these phases it's called a template and a tags dictionary, from the union of these two elements you get the output g-code.

Templates

Here an example of a template , which is nothing more of plain text .

Inside this text , you can see some word between curly brackets. These are the TAGS.

{EMPTY_LINE}

{LINE_N}

({OP_DESC})

{RADIUS_COMP_INFO}

({TOOL_LABEL})

T{TOOL_POS}M6

{NEXT_TOOL_POS}

{FEED_MODE}

S{SPEED_VALUE}{SPINDLE_ORIENTATION}

{ORIGIN}

{COOLANT_CODE}

Tags Dictionary

The tags are the variable values, here an example of a tags dictionary.

LINE_N = N5 TOOL_POS = 15 NEXT_TOOL_POS = 10 FEED_MODE = G98 SPEED_VALUE = 2387 SPEED_ORIENTATION = M3 ORIGIN = G54 COOLANT_CODE= M8

Output Final Code

From the combination of the single template and the tag dictionary, the output g-code will be created.

N5 (CONTOUR - ROUGHING) (COMP COMPUTER - RADIUS COR VALUE 10) (R390 D 20MM) T15M6 T10 G98 S2387M3 G54 M8 ...

The tag value will replace the {TAG_WORD} in the template.

Dictionary Convention

To facilitate understanding of the parameters available in the dictionary , it's been used a convention for naming tags.

Suffix _CODE :

These tags values are complete with both the char ( F, G, M) and numeric part ( 100, 0.3)

example :

{FEED_CODE} => F.3

{SPEED_CODE} => S100

Suffix _VALUE :

These tags values contain only the numeric part ( 100, 0.3) .

example:

{FEED_VALUE} => .3

{SPEED_VALUE} => 100

Thread Table

In Alexsys is available also a thread database for the most used thread tables.

This mean you don't need to search diameter or pitch values to create machining operation.

Just select the desired thread item from a list to compile all the necessary data.

To open thread table dialog , from menu click EDIT and then THREAD TABLE

Add custom data

This database can be expanded with custom data.

Open the thread table dialog.

- Select the desired thread family ( category)

- Insert the new values in the last row of the table.

To find reliable thread information , search directly from tool builder website. There you can find more information about everything . Suggested pass count,thread depth and angle , predrill and some useful tips about thread machining.

Edit Pitch

To edit pitch value , simply click on [Pitch Details]

Is possible to edit :

- External Thread Height

- External Passes Count

- Internal Thread Height

- Internal Passes Count

Edit Category

Also the thread category are editable.

Is possible to edit :

- Description

- Unique Id

- Select between TPI and Pitch values

- If is tapered or not

- Taper Angle

This information will be used in code generation.

If you want to hide the a category, check the "HIDE THIS CATEGORY FROM DROPDOWN THREAD LIST" field.

3D Stock Model

In Alexsys the 3D stock is modeled with defined machining operations.

From preference dialog you can choose how the model is created . From Menu -> Edit -> Preferences -> 3D Model Creation Mode

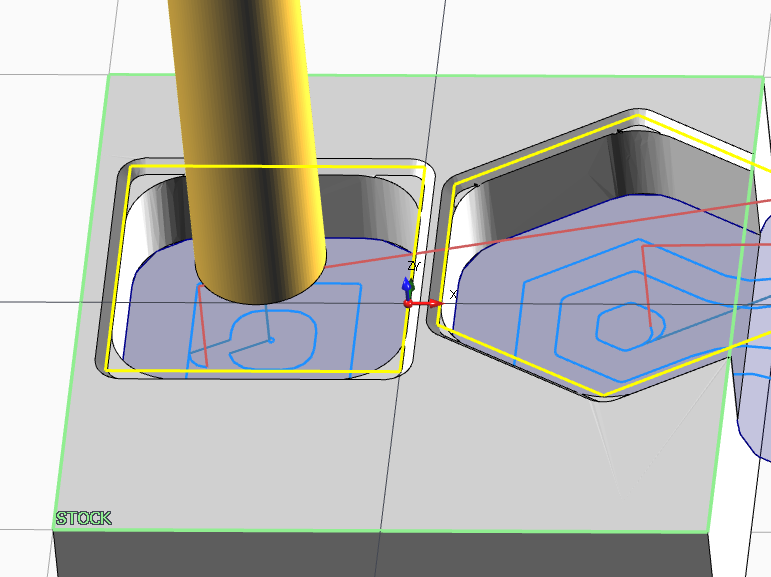

1 ) By Toolpath

The generated 3D model, is the effective result of the toolpath movements.

In this way you can see if there something wrong with generated toolpath.

For example, in the case below you can see the material left in the corner from the end mill machining. This is what you get on real machining.

[Simulation Stock Quality] is related to the stock in simulation context.

[Static Stock Quality] is related to the stock modeled in viewpoint context.

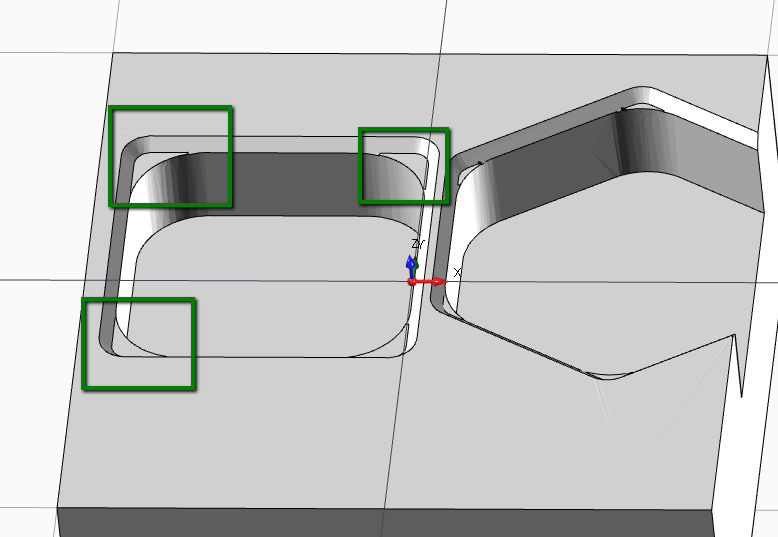

2 ) By Work Properties

This generation mode is usually faster , especially for simple 3D model, but it doesn't reflect the effective toolpath.

Some work machining like threading and engraving are not elaborated .

In the example below you can see the model is not considered the corner radius of the pocket. It's just used the profile and work parameter to model the stock.

Textbox integrated calculator

Every numeric textbox has an integrated expression solver.

This mean you can insert expression like " ( 6+6 ) * 2 ", and when you leave the textbox field, in the text box will convert it to 24 as result.

Unit Conversion

Is also possible unit conversion , from [mm] to [inch] and from [inch] o [mm] units.

Just insert [mm] or [in] suffix at te end of inserted value.

Example:

In a [mm] unit file instance, set as text " 1 in " or 1 inch in any numeric textbox .

The value will be converted in 25.4 mm .

Timeline

In the window application bottom , is visible the timeline control.

1) It's the time of current selected operations.

If you hover this label, you can see the timing grouped by setup, if you have multiple setup in your project.

2) Here it's a graphical representation of machining time of each operation.

The purpose of this graphic is too see at glance what operations are taking most of the machining time.

Every operation has a different color, if you hover it with mouse cursor you can see the related operation in the viewpoint.

Click on color bar to select related operation.

Manual Code

With [Manual Code] operation , is possible add manual text in output g-code program.

Load Template : Load existing gcode.

Description : It's the name of current template . It's used as identifier when you need to save , load or delete a template.

Insertion Mode :: Write only g-code : In output gcode related to this operation, you get the imputed text without any other command.

Insertion Mode :: Call Tool + Manual Code : In output g-code related to this operation , you get also the tool change and tool disengagement logic.

Save Template : Save the current text as template. You can find it in template list after this.

Delete Template : It will delete the related template from list.

G-Code Text : It's the manual g.code text you are going to add in output code.

Note : The "manual g.code" operation is just to add plain gcode to output text.

Simulation of this operation is not meant to be good , it will read only linear movements.

Macro , M-Codes , CRC compensation or other commands are not elaborated.

Stock Materials

In Alexsys is possible define several stock materials.

The purpose of having several stock material is to give the possibility to save different tool cut-data for the same tool.

Example :

With the same End-Mill :

-> if you are going to work mild steel , the software will select related cut data parameter for mild steel

otherwise

-> if you are going to work aluminium , the software will select related cut data parameter for aluminium

Default Material List

By default you have 3 material available:

- Mild Steel

- Stainless steel

- Aluminium

To open the material dialog, first you need to open tool table :

From Menu -> Edit -> Tools

then click [EDIT STOCK MATERIALS] from tool table.

The button is available only when you open tool window from menu.

When you open tool window in "Tool Selection Mode" this action it's not enabled

Below the MATERIAL LIST window.

Create New : Add a new material to the list. See below the properties you need to edit.

Delete : It delete permanently selected material. It not suggested delete materials after using it in some project.

Save And Close : Save user edits and close the window

Material Properties

Unique Id : This is an auto-calculated property. It's the combination of [Material Group] and [Material Grade] properties.

1) Is important have a different unique id for each material. This property is used to retrieve the cutting data parameters related to the material.

2) Don't change this id from existing material , since you are going to lose all the referenced cutting data .

Description : This is the description you are going to see in home treeview or in combobox in the tool store dialog.

Material Group : You can consider this as the material main category . The common group are P - M - K - N - S - H

Material Grade : For the same material group you can have different material grades. Insert the value in this field.

Material Group and Grades are used from tool builder to classification the various material of component part.

Here and here , some tools website with more information about this classification.

Specific Weight : Right now this property it's not used from the software. It's planned a method to give to the user the weight of the stock. So it will come in handy in the future.