SOURCE Tool Setters and Offsets

Open the Calibrate Tool Setters window. Found on the Tools tab.

Creating a Manual Tool Setter

-

In the Tool Setter tab, click Add New to create a new tool setter.

-

Enter a unique name for the tool setter.

-

Select the new tool setter from the list to display its settings on the right side.

1. Setter Type

-

Under Setter Type, select Manual.

2. Tool Setter Height

-

Measure the physical height of the tool setter.

-

Enter the measured value in the Tool Setter Height field.

3. Z Position

-

For a fixed-mounted setter:

-

Use the Z Position Wizard to determine the machine coordinate for the top surface of the setter.

-

Once set correctly, this value should not be changed.

-

-

If the setter is mounted outside the soft limits, enable Disable Softlimits.

4. GoTo Position (Optional)

-

Define a GoTo Position so the spindle can safely move to the tool setter before touch-off.

-

This ensures a consistent and safe approach, reducing the risk of collisions.

Once the Z position and height are calibrated, the system will automatically use these values for all tool length offset calculations.

Randomly placed tool setter

-

Set Initial Parameters

-

Set the Z Position to 0.0.

-

Leave all GoTo fields blank.

-

This indicates that the setter position may change between uses.

-

-

Prepare the Spindle

-

Remove all tools from the spindle.

-

If the spindle uses tool holders or collets, insert an empty holder while setting the Z position.

-

-

Position the Tool Setter

-

Place the manual tool setter or gauge blocks on the table at the desired location.

-

-

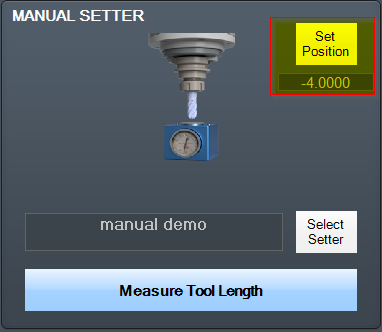

Set the Z Position

-

Carefully jog the spindle down until the tool tip touches the surface of the setter.

-

Click Set Position.

-

This records the Z position using the current spindle location and the entered Tool Setter Height value.

-

-

Measure Tools

-

Insert each tool required for the job.

-

Perform a tool measurement cycle for each tool to record its length offset.

-

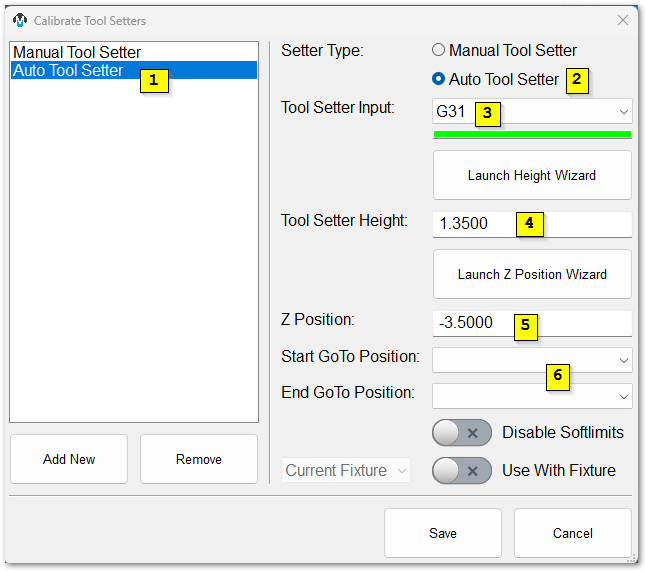

Creating an Auto Tool Setter

|

|

|

-

Click Add New to create a new tool setter.

-

Enter an appropriate name for the tool setter.

-

-

Set the Setter Type to Auto.

-

Select the Probe Input that the tool setter is wired to.

-

The indicator bar below the input selector will turn green when the tool setter is triggered.

-

Manually trigger the setter (or have a helper do so) to confirm the correct input is selected.

-

-

If the tool setter height is known, enter the value in the Tool Setter Height field.

-

If the height is unknown, click Launch Height Wizard and follow the on-screen instructions to measure it.

-

The tool setter must be wired to the control for this process.

-

-

Set the Z Position to the machine coordinate of the surface where the tool setter rests.

-

If the position is unknown, use the Z Position Wizard to determine it.

-

For a randomly placed setter, set the Z Position to 0.0. This value will be defined each time before measuring tools.

-

See also: Using a Randomly Placed Tool Setter.

-

-

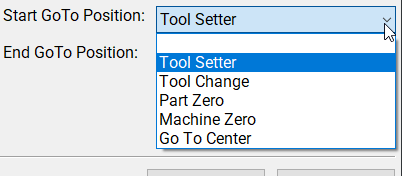

(Optional) Define GoTo Positions for the tool setter.

-

Selecting a GoTo position allows the spindle to move automatically to the setter before touching off.

-

This is recommended for permanently mounted setters.

-

If the setter is located outside the soft limits, enable Disable Softlimits.

-

-

For randomly placed setters, leave all GoTo Position fields blank.

-

Manually jog the spindle to the setter or place the setter beneath the spindle as needed.

-

The machine will not perform automatic jogging during this process.

-

Align Tool Edge to Center of Tool Setter

-

Enable the feature by setting Tool Setter Align Tool Edge To Setter to Yes.

-

Configure the Tool Setter Align Tool Edge Offset parameter.

-

Choose between Tool Radius or Tool Setter Offset as the source for the offset used to align the tool edge to the center of the setter.

-

-

Select the Offset Direction to define which way the tool moves when aligning the edge to the center of the setter.

This feature positions the edge of the tool precisely at the center of the tool setter, ensuring accurate alignment and consistent measurement results.

Configure the following Parameters:

| Parameter Name | Value | Optional Values | Default Values |

| Tool Setter Align Tool Edge To Setter | Yes | No | |

| Tool Setter Align Tool Edge Offset | Tool Setter Offset | Tool Radius, Tool Setter Offset | Tool Radius |

| Tool Setter Align (X or Y) Axis To Setter | X Positive | X Positive, X Negative, Y Positive, Y Negative | X Positive |

MachPro setting "Tool Setter Align Tool Edge Offset" must be set to "Tool Setter Offset" before the Tool Setter Offset column will be visible in the tool table. Configure -> Control -> Settings tab in the Measuring and Offsets section

Modifying GoTo Positions

If you are setting up the GoTo position for a tool setter, jog the tool to the correct position over the tool setter.

Now select the GoTo Positions tab tab.

Position Setup Instructions

-

Use the Add or Remove buttons at the bottom to manage positions.

-

When adding a new position, choose Machine Coordinates or Part Coordinates at the top.

-

To change an existing position, select it and edit as needed.

-

Each position builds a movement list in the Data Box. Use Delete to remove a movement.

- To add a custom G-code line, write it and click Add to include it in the Goto list.

⚠️ Do not use M Codes here.

This helps move the tool safely before other operations.

Add Movement Instructions

-

Click Include for each axis you want to move.

-

Click Get Current Position to copy the current coordinates, or type the coordinates manually.

-

Click Add/Update to save the movement in the Data Section.

Example: Z-Axis Movement

-

Define the Z-axis movement to run first.

-

Click Add/Update to insert this movement into the Data Box.

-

Add more actions in the next rows.

-

Optionally, add a final Z Rapid Move to bring the tool close to the setter.

I modified the Tool Setter position. Coordinate lines in the Data box will be in Machine Coordinates. This will be used as the Tool Setter position and can be called using the P2 variable.