Dold Safety Relay

MachMotion uses Dold safety relays on many electrical enclosures to provide the right level of safety needed in an emergency condition.

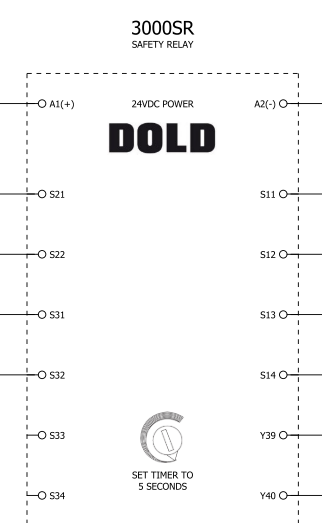

Delayed Safety Relay

A delayed safety relay is used to allow time for a spindle motor or other function to safety stop before removing the power or the Safe Torque Off turns off (STO).

BH5928-92-61-24-30

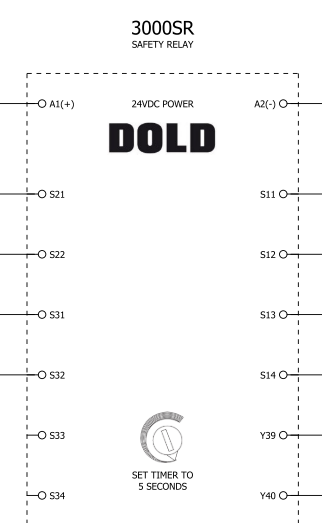

Non-Delayed Safety Relay

LG5925-48-61-24

Troubleshooting

Safety Relay Not Reset Alarm

| Cause |

Possible Solutions |

| No Power |

TroubleshootingConfirm the power LED is on (Netz LED on the top left)

|

| E-Stop Connections Open |

Check the schematic on page 30 to figure out if there is one Estop channel or two.

Dual Channel

- Confirm Watch Dog Relay is connected.

- Confirm S21 and S22 are connected at the safety relay (check for continuity with a multimeter)

- Confirm S31 and S32 are connected at the safety relay (check for continuity with a multimeter)

Sigle Channel

- Jumper S11 and S12 out at the safety relay to confirm it enables.

|

| Dual Channel E-Stop Connections Timing Different |

- Replace the estop buttons

|

| Reset Output Not Activating Correctly |

- Check the parameters in the MachMotion Plugin for Safety Relay. Is the output mapped and turning on correctly?

|

| Apollo III Hardware Enable Off |

- Confirm HEN LED is on on the Apollo III. You can force the Hicon Port 14 Pin 0 on under diagnostics and test it.

|

| Safety Relay Jumpers Incorrect |

- Check the schematic on page 30 to see if the jumpers on the S and Y signals are correct.

|

| Timeout Delay Too Short |

- Check the parameters in the MachMotion Plugin for Safety Relay timeout delay. It must be longer than the safety relay time delay value. For example, if the safety relay is set to 10 seconds, the delay in the MachMotion Plugin must be at least 12,000 ms.

|