Orion 3000 Controller

{{@672}}

This manual provides an overview the features of the Orion 3000 controller.

1. Overview

The Orion 3000 control is an industrial PC control with an integrated 21.5" touch screen and operator panel.

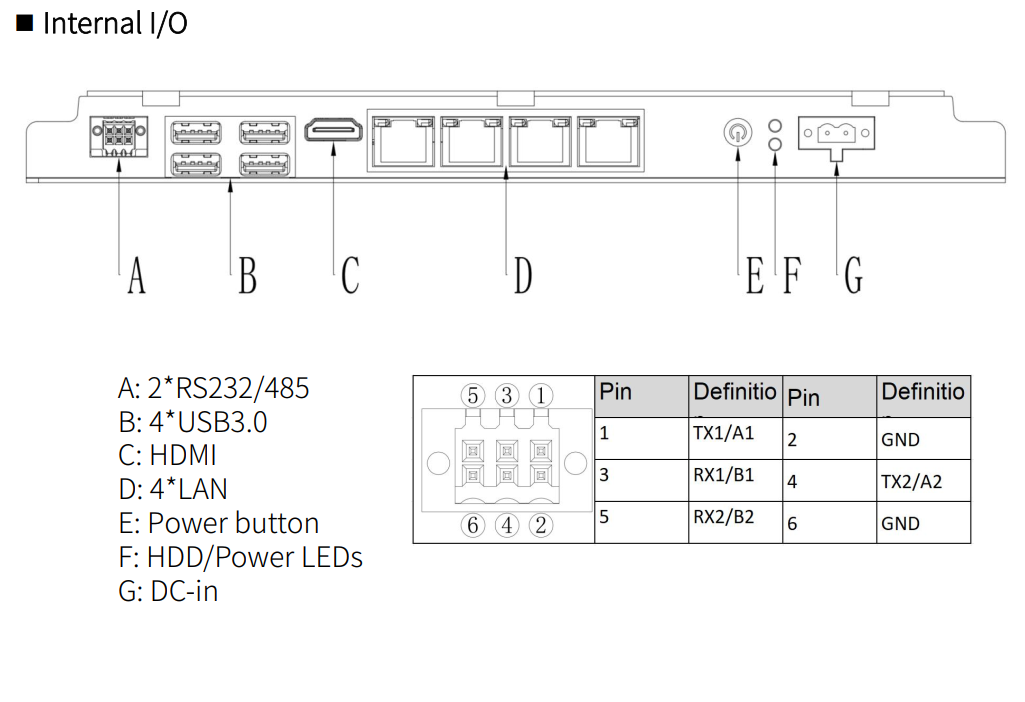

2. Connections

3. Features

- 21.5” LCD,1920*1080,resolution,Multi-touch,Capacitive Touchscreen

- Full IP65 design

- 2/4*Glan/4*USB3.0/1*HDMI/2*COM

- DC12-24V power input

- Support ARM mounting from TOP side or BOTTOM side

- Fanless and anodized aluminum

4. Specifications

| Category | Specification | ICP69215-C-H52-4Y |

| LCD | Size | 21.5" LCD |

| Resolution ratio | 1920*1080 | |

| White Luminance | 250cd/m2 | |

| MTBF (hour) | 30000 hrs | |

| Contrast Ratio | 3000:1 | |

| Viewing Angle | (L)89 / (R)89 / (T)89 / (B)89 | |

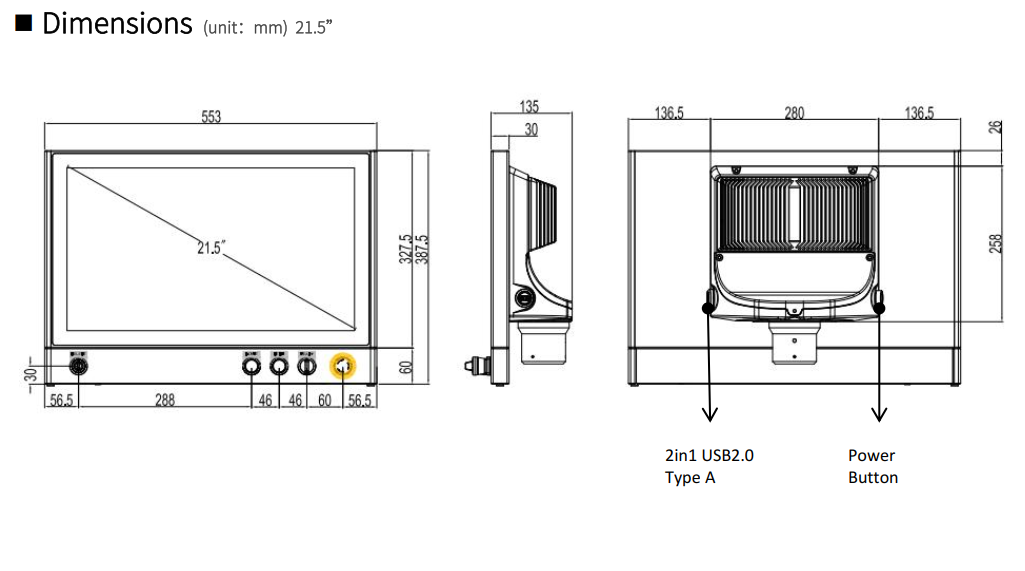

| Mechanical | Dimensions (W x H x D) | 553mm x 387.5mm x 135mm |

| Installation | Swing ARM mounting (Support NODKA 4460 square tube and Rittal CP 40) | |

| Buttons | ||

| Weight | 9.0 Kg | |

| System | CPU | Intel® Core™ 10-11th |

| Memory | 2 x 260-pin DDR4 SODIMM, |

|

| Storage | 1 x 2.5" HDD/SSD + 1 x mSATA | |

| Network (LAN) | 4 x Intel 1000Mbps Ethernet | |

| HDMI | HDMI 1.2 | |

| Serial ports | 2 x RS232/485 (optional), 2 x 3-pin Phoenix Connector | |

| USB | 4 x USB (3.0/2.0/1.0) | |

| Touch screen | Touch screen type | Capacitive Touch screen |

| Communication interface | USB | |

| Transmittance | ≥87% | |

| OS | OS | Windows |

| Power Consumption | Input Voltage |

12-24VDC ±10%; reverse connection, over-voltage, over-current protection; 1x 2-pin Phoenix DC (internal); 1x power button with light (back) |

| Idle Power Consumption | Minimum 35W | |

| Environment | Operating Temperature | 0°C ~ 50°C for SSD; 0°C ~ 45°C for HDD |

| Storage Temperature | -20°C ~ 60°C | |

| Humidity | 5~95% @ 40°C (non-condensing) | |

| Vibration | SSD applied: 1.5 Grms, IEC 60068-2-64, random, 5~500 Hz, 1 hr/axis | |

| Shock | Operating 10G peak acceleration (11ms duration), follow IEC 60068-2-27 | |

| EMC | Class B | |

| IP rating | Full IP65 |

5. Mechanical Drawings

6. Operator Panel

Emergency Stop should be used in the event of an emergency and as a safety precaution any time the machine isn't running. Emergency Stop will not lose position of machine or require rehoming.

Cycle Start can be used to start a G-Code file and is also used to start other commands such as MDI and GoTo Commands.

Feed Hold is used to pause motion during file run and will leave the spindle on. Cycle start will resume motion and continue file execution.

Reset is used to clear alarms and set the machine back to default modals. These defaults can be changed in the Initialization Codes sections of the default control configuration. Reset also does a full cycle stop and rewinds the GCode file.

USB two USB A ports

Jog - and Jog + are integrated with on-screen controls where you can select the axis to be jogged