On-Site Yaskawa V1000 / A1000 / GA500 Modbus VFD Installation

1. Wiring

Control Cable: The VFD Control cable is the green Ethernet cable that runs from the Yaskawa VFD to the Control PC as shown in Figure 1. Or if you have an Apollo III motion controller, connect the VFD control cable into Ethernet 1 Port on the Apollo III.

(Figure 1 Ethernet Connection to Control PC)

Spindle Motor: Connect your spindle motor to the terminals labeled U/T1,V/T2, and W/T3 as shown in Figure 2. If your spindle moves the wrong direction when you turn it on, just swap any three of the (U,V,W) leads.

(Figure 2 Spindle Motor Connections)

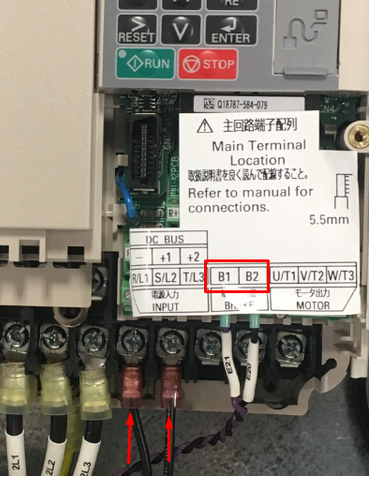

Brake Resistor: Connect your brake resistor by placing the two wires on the +2/B1 and B2 terminals as shown in Figure 3.

(Note: If needed to extend the wires use High Temp rated wire.)

Mount Resistor: Mount the resistor to the cabinet. Wire as shown in Figure 3.

(Figure 3 Yaskawa Resistor Connections)

Thermistor: If your spindle has a thermistor, please make sure to connect it. Use the following knowledge base from Yaskawa for more information: Motor Protection Using Positive Temperature Coefficient (PTC) Thermistors. You must also switch the A3 dip switch (analog 3 input) to Voltage.

2. Programming

VFD Programming

Your VFD should already be configured for use as a Modbus or EtherCAT device.

This programming will configure the VFD for the specific hardware and application of this system. To program the VFD you will need to utilize the Mach4 software. While the control is disabled follow the next steps.

Step 1: Click on Configure -> Plugins -> MachMotion (as shown in the pink box in Figure 4).

(Figure 4 Access the MachMotion Plugin)

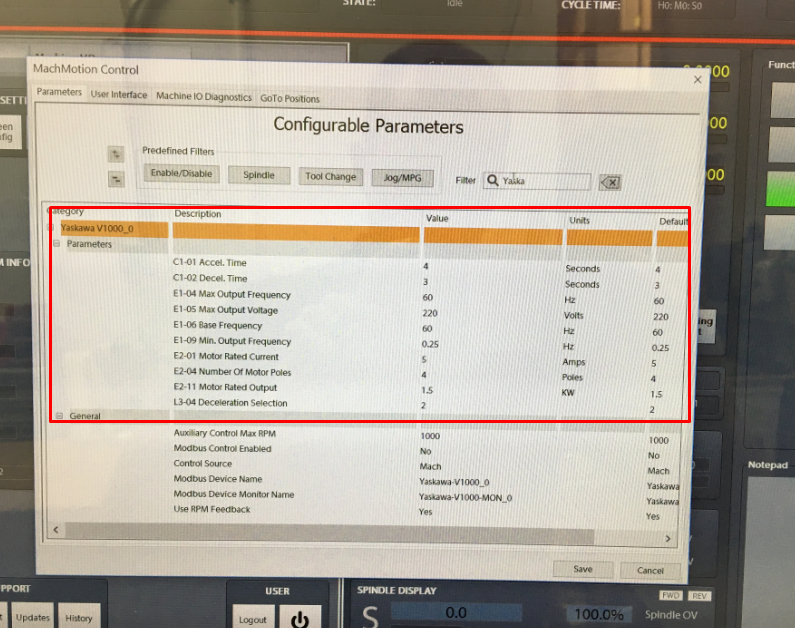

Step 2: While in the MachMotion Plugin Type "Yaskawa" in the search field as shown in Figure 5.

(Figure 5 Search Field)

Step 3: This will display the parameters for the Yaskawa VFD V1000. Note that if there are multiple VFDs, then the additional units will be labeled V1000_1, V1000_2, etc.

Note: All Mach Parameters will be labeled as "Yaskawa V1000_0" for V1000, A1000 and GA500 type VFDs.

(Figure 6 Yaskawa V1000 Default Parameters)

Step 4: Enable the VFD.

For a main spindle, set the values to these values:

For large VFDs you must also select Drive Capacity to Large or the VFD will run at only 10% of the commanded speed. Set the Drive Capacity according to this table: https://support.machmotion.com/books/motors-drives-and-vfds/page/yaskawa-vfd-capacity-tables.

Older VFDs had a different parameter set and the Output Command Type was set to Frequency.

If you are getting incorrect results, try changing the Control Source Command Type from RPM to Percentage.

For any other spindle like a grind wheel, regulating wheel, or sub spindle, set:

Step 5: Set up the motor parameters

Find your motor nameplate and enter in the parameters based on the table below. The default values are in Yaskawa GA500 Iindustrial AC Microdrive Technical Reference starting with section 11.18. That is for different control methods and drive classes.

If you have a Baldor SuperE motor, use the parameters and instructions from this article.

If you cannot locate the motor’s base frequency, the name plate should tell you how many poles there are on the motor. You can also call the motor manufacturer to figure out the number of poles. Using the motor’s maximum RPM and its number of poles, you can calculate the base frequency with the formula below:

Motor Poles = 120 * Max Hz / Max RPM

RPM = 120 * Hz / Number of Poles

Base Frequency = Rated RPM * Number of Poles / 120

Max Frequency = Max RPM * Number of Poles / 120

Gear Ratio = Input RPM / Output RPM

Yaskawa Parameters entered from the MachMotion plugin

| Parameters | Description | Default | Range |

| C1-01 | Accel. Time | 4 |

0.0 to 600.0 Seconds |

| C1-02 | Decel. Time | 3 |

0.0 to 600.0 Seconds |

| E1-04 | Max. Output Freq. | 60 |

40.0 to 400.0 Hz |

| E1-05 | Max. Output Voltage | 220 |

1.0 to 510.0 Volts |

| E1-06 | Base Frequency | 60 |

1.0 to 599.0 Hz |

| E1-09 | Min. Output Freq. | 0.0 to 599.0 Hz | |

| E2-01 | Motor Rated Current | 5 |

Amps from Motor ID plate, or 10% to 200% of drive rated current |

| E2-03 | No Load Current | 40% of Motor Rated Current | |

| E2-04 | Number of Motor Poles | 4 |

2 to 20 Poles |

| E2-11 |

Motor Rated Output V1000 GA500 |

|

0.00 to 650.00 kW use kW value use HP value (kW * 1.341 = HP) |

Yaskawa parameters entered from the Yaskawa DriveWizard

| Parameters | Description | Default | Range |

| C1-09 |

Emergency Stop: time to decelerate to stop |

3 |

0.0 to 600.0 Seconds Decelerating too quickly can cause an ov [Overvoltage] fault that shuts off the drive |

| C6-02 |

Carrier Frequency Selection |

02 |

Used on High Speed Spindles to set Carrier Frequency to 5KHz. For HSD spindles use this manual to set Carrier Frequency: HSD Spindle with Yaskawa VFD Setup. |

| E1-07 |

Mid Point A Frequency |

((E1-04 – E1-09) / 2) + E1-09 (see notes in next section) |

|

| E1-08 | Mid Point A Voltage | ((E1-05 – E1-10) / 2) + E1-10 (see notes in next section) |

|

| E1-09 | Minimum Output Frequency | 0.5 |

0.0 to 599.0 Hz |

| E1-10 | Minimum Output Voltage | 0.0 - 255.0 Volts |

|

| L3-04 | Deceleration Selection | 3 |

0 = Disabled 1 = No Brake Resistor 3 = Brake resistor |

| L8-07 | LF Output Phase Loss | 0 |

Sometimes we need to set this to 0 to disable that alarm |

Calculating the mid point values for frequency and voltage

Any time you change any of the E1 or E2 parameters, you must restart Mach4 to get the new parameters to download into the VFD. It is a good idea to restart Mach4 after entering any of these parameters.

DC Injection Braking

For advanced applications, you may need to use DC Injection Braking.

| Parameters | Description | Default | Range |

| B1-03 | Stopping Method | 02 |

00 = Ramp to Stop - use this 02 = DC Injection Braking to Stop - which will make it too hot. Do not do this. |

| B2-01 | DC Injection Start Frequency | [ E1-09 ] |

Set this to the same value as E1-09 - the minimum output frequency. When commanded frequency drops below this number, it will activate the brake. E1-09 is also the point at which the braking resistor will let go. |

| B2-04 | DC Injection Time At Stop | 0.25 | This sets how long you want DC injection braking active. 0.25 may be plenty. 0.5 may be too long. |

| H1-05 | Set to 60 to have S5 activate DC Injection Breaking Mode for Orient or other related function. | 60 | N.A. |

If you get an OC or OV fault on deceleration, L2-03 parameter may be set too low for the size of the motor. Range 0.2 - 1.0 seconds.

Yaskawa GA500 Versatile Compact AC Drive Technical Reference SIEPC71061752

Fast Stop

To get the full performance life out of the electrolytic capacitors and circuit relays, refrain from switching the drive power supply off and on more than once every 30 minutes. Frequent use can damage the drive. Use the drive to stop and start the motor. A Fast Stop can be used for an application that requires frequent shutdowns without having to cycle incoming power. Fast Stop operation uses a deceleration time set on parameters C1-09. The drive cannot be restarted after initiating a Fast Stop operation until deceleration is complete. Complete deceleration and cycle the Run command to clear the Fast Stop input.

Note: Fast Stop function may not be fast enough for an Emergency Stop with a high inertia load.

| Parameters | Description | Default | Range |

| C1-09 | Emergency Stop Deceleration | 3 Seconds | 0.0 to 600.0 Seconds Time to full stop. Same as C1-02 or less? |

| H1-07 |

Fast Stop (N/C). By default Yaskawa sets S7 to Fast Jog which will allow the VFD to run when you command it but only at a locked speed and only in one directly (one direction as far as we know). |

17 |

Fast Stop – set H1-07 to 17, and set C1-09 to the time for it to come to a complete stop. If it decelerates too quickly, the drive will fault with an OV over voltage alarm. |

Spindle Calibration

All the instructions for spindle calibration can be found in VFD - Spindle Calibration

Troubleshooting

SCF Alarm

Note: If you get an SCF alarm on deceleration:

- DC injection breaking is enabled and the carrier frequency needs to be adjusted. Set C6-02 to 2 (for high frequency jobs change C6-04 to 2 and C6-03 to 5khz). Changing the carrier frequency allows for a more sinusoidal wave on the output and it does not interfere with the safety circuit.

- Although the Yaskawa manual says it's only caused be a safety relay input issue (and likely a bad drive), we have found that making changes noted above will often resolve the alarm.

Random Estop Alarm During Spindle Run

If the Keyance safety relay trips out, check the following:

- Check the spindle ground.

- Set C6-02 to 2 (for high frequency jobs change C6-04 to 2 and C6-03 to 5khz). Changing the carrier frequency allows for a more sinusoidal wave on the output and it does not interfere with the safety circuit.

Deceleration

If you have issues getting the spindle to stop completely try setting B2-04 to 2.00sec

RPM Incorrect

If the VFD is setup correctly but the VFD does not go the correct RPM, check the S7 input. For a delayed safety relay S7 must be set to Fast Stop (N/C) or H1-07: 17. By default Yaskawa sets S7 to Fast Jog which will allow the VFD to run when you command it but only at a locked speed and only in one directly (one direction as far as we know). For more information, see Yaskawa V1000 / A1000 / GA500 / GA800 TCP Modbus Communication Setup.

Webpage

For TCP modbus VFDs, you can go to the webpage to view the status of the VFD. Normally the IP address is 192.168.208.90.

VFD Monitor Panel

You can use this panel to test VFD operation.

Alarms

If you were to get an alarm on the VFD you will receive a message on the computer screen from the Global Message System. In the description of the alarm it will describe the necessary steps to try to resolve the alarm.

Setup Verification

To test any modbus VFD, review the following items to confirm it is setup correctly:

Does the VFD run the spindle? The VFD RUN light should be on solid when it is up to speed. If it isn't, the VFD is not programmed correctly.

Does the RPM change when you change the spindle speed on the control?

Does the VFD go both directions?

If you disconnect the VFD control cable does the control time out with a VFD Disconnected Error?

Is the RPM feedback correct?

Does up to speed and at speed work correctly inside the control?

Appendix

Default IO Mapping

Modbus

Inputs

Outputs - none required.

Spindle Load

Apollo III

Make sure the VFD is powered all the time. Otherwise the VFD will not connect correctly.

Wire the Estop circuit as shown below:

Warranty Information

MachMotion warranty policy is subject to change. Updated information is available at our website:

https://machmotion.com/warranty

The MachMotion Team

http://www.machmotion.com

14518 County Road 7240, Newburg, MO 65550

(573) 368-7399 • Fax (573) 341-2672