Yaskawa Analog Monitor Output

Sigma 7 Pulse and Direction Drive

Wiring

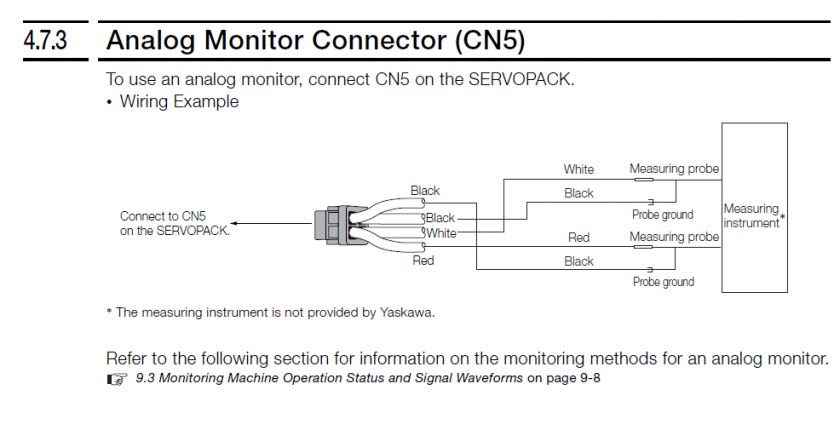

Wire the analog input to the analog monitors on CN5.

Use a cable as shown below:

Setup Options

Factor and Offset

Load Meter

Analog Monitor 1

Pn006=.XX02

Calculate the value of Pn552 based on the max rated torque you will ever see on this device:

Pn552 = 10V / (0.01 * Max Rated Torque %)

| Max Rated Torque % | Pn552 |

| 40% | 25.00 |

| 50% | 20.00 |

| 100% | 10.00 |

| 300% | 03.33 |

For example, if you want to see up to 50% of rated torque, calculate it as follows:

Pn552 = 10V / (0.01 * 50%) = 20.00 so you would set Pn552 to 20.00.

Default for reg wheel on centerless grinders pn552 =100. Reg wheel torque is so low you will not see the load change unless on a machine.

Proof:

Actual Output Voltage = Pn552*0.01 * Actual Rated Torque %

Substitute Max Output Voltage for Actual Output Voltage and Max Torque for Actual Rated Torque:

Max Output Voltage = Pn552*0.01 * Max Rated Torque %

Solve for Pn552:

Pn552 = Max Output Voltage / (0.01 * Max Rated Torque %)

Set Max Output Voltage to 10V:

Pn552 = 10V / (0.01 * Max Rated Torque %)

Mach4 Setup

If using the Siemens PLC, see this document: Siemens PLC - Wiring SM1234.

Reference Manual: See attached Sigma-7 Manual Analog-Pulse.pdf

Keywords: Load meter, spindle load