2000 Series Universal Cylindrical Grinder Operating Manual

Introduction

The 2000 Series Universal Cylindrical Grinder control is a two-axis CNC system for OD/ID grinders.

The system includes standard dressing and grinding macros for common straight, tapered and profile geometries with a more simplified G code program. With its familiar windows interface, intuitive graphics, and user friendly layout, the system is easy to learn. Allowing you to have the machine operational almost immediately

The control also accepts standard Fanuc standard G-code, as well as Fanuc Macro B programming compatibility, giving operators virtually unlimited capabilities for writing their own custom programs and macros.

This manual gives the process for basic operation of the 2000 Series Cylindrical Grinder control including a summary of the different features of the pages and additional screens.

Screen Navigation

Run Page

The run page contains the necessary features for operating the machine. The left side of the screen contains buttons for loading, editing, and running programs as well as the live tool path window to see the path the machine will take when the program is run.

The center of the screen contains information about machine status. The feedrate, wheel head RPM, and workhead spindle RPM can be modified on the fly by typing a new value in the blue box.

The wheel head will be adjusted as a percentage of the RPM you set in the Grinder setup>Wheel Head Setup screen. (Wheel RPM value) See Wheel head Setup below for more information.

On the right side of the screen is a dashboard that can be configured with any number of widgets based on the operator's preferences (See the Series 2000 User Manual). Seen in the example above is the tool wear offset input window which can be used to make slight adjustments to the part diameter, the part offset table (Part Correction Offset) which, when multiple features are being ground on the part, can be used in conjunction with an "E" variable in the program to allow adjustments to each feature individually.

Conversational Page

The conversational page is used to quickly and easily create new grinding and dressing programs without manually writing gcode. A program consists of a set of cycles that are included in the job. The cycles can be added to the job in any order and rearranged or removed as needed. Adding a cycle is a matter of selecting the type of cycle, inputting the dimensional data, and pressing Add to Job. Once all cycles are correct, the Post button will load the job for running.

Grinder Setup

The grinder setup screen is used to set up the grinding wheels, dresser options, and safety clearances.

Wheel Head Setup

This page is for setting up wheel head parameters for the active wheel. These parameters affect how the cycles run and how the wheel is dressed.

Dresser Setup

This page is for setting up the dresser diamonds on the machine. There are three types of diamonds supported here:

- Profile dresser: used for dressing circumference and or one side of wheel, as well as user developed wheel profiles.

- Universal dressers: two dressers are used for dressing forms that exceed 90 degrees of travel into or around the wheel that cannot be done with a single dresser. For example, a full radius dressed into or onto the circumference of the wheel, or radii or profiles on both corners of the wheel.

- Straight dressers: used for straight dressing of all three surfaces of the wheel.

Safety Clearances

This page sets the distances between wheel, part, and diamond that are considered safe. These should be configured before running parts or dressing a wheel.

Rotary Dresser

If the machine has a rotary dresser, it's parameters are set on this page.

Measuring Devices

The Measuring Devices page is used view, setup and calibrate the measuring devices that are enabled on the machine.

Calibrate

The calibrate page is used for calibrating the grinding wheel to the part and adjusting the part size. The axes are brought into position, touching the part, and taught that position. The part is then measured at that position, and the position is updated to adjust for any discrepancy.

Fixtures

The fixtures screen is used for setting fixture, machine, and or work offsets.

Service

The service screen gives access to machine settings and diagnostics. It also contains a second configurable dashboard that can be setup to user preferences.

Maintenance

The service screen is used for control set up, diagnostics, and getting remote help from the support team.

Machine I/O

This page allows the operator to see the state of all configured signals and I/O that are in use on the machine.

Operations

X Axis Direction

External OD

When grinding External the Grind Wheel will normally be on the far side of centerline away from the operator. All diameters are entered in the positive space starting from a larger diameter for the start and ending with a smaller diameter.

Internal ID

When grinding Internal the Grind Wheel will normally be on the same side of centerline as the operator. All diameters are entered in the negative space starting from a smaller negative diameter for the start and ending with a larger negative diameter.

Before Running A Part

Before running parts on the control, be sure the following steps have happened after starting the control software:

- Machine is homed

- Wheel selection is correct

- Safety clearance positions have been taught

- Dresser diamond positions have been taught

- Wheel has been rough dressed

- Wheel has been calibrated to the part

- Flagging device has been calibrated to the wheel

Homing Machine

Most machines are configured with a Enable and Home dialog that will be shown on startup.

Press the Cycle Start button on the dialog or the Cycle Start button on the operator panel. The machine will enable the servos and home to the switches.

If for some reason this dialog is not shown you can manual enable the machine by pressing Reset and then navigate to the Service page.

Home each axis individually or press Home All to home all axes.

Wheel Selection

The Tool Display is always visible and should be used to confirm which wheel offsets and data are active.

All wheel data and dresser data is stored in the tool table. This allows the control to store multiple wheels each with different wheel specs and dresser positions. Wheels are called with the Tool Change call similar to a Turn controls, the first two digits are the wheel number (pocket number) and the second two digits are the tool offsets.

- T0101 will activate wheel #1 and tool offset #1

- T0202 will activate wheel #2 and tool offset #2

There are a few special tool offsets used for Flagging and the diamonds when dressing. The "xx" represents the wheel number.

- Txx91 will activate the offsets for Diamond #1

- Txx92 will activate the offsets for Diamond #2

- Txx93 will activate the offsets for Diamond #3

- Txx95 will activate the offsets for the Active Flagging Device

Use MDI and Cycle Start to select wheel #1 "T0101".

Or on the Calibrate page there are buttons to select a wheel.

Safety Clearances

Safety Positions

Safety Positions are the positions from Machine Zero that the wheel will follow when retracting from the part and moving to the dresser. See Positioning to Dress for more info on the path between part and dresser.

When the machine wheel retracts from the part to the dresser it will follow the following path:

- X will move to the Xsw position

- Z will move to the Zs position

- X will move to the Xsd position

Using the operator panel Jog the machine to different positions and set the position with the yellow TEACH buttons.

When using an OD grind wheel Xsw and Xsd should be set to the same position.

Safety Wheel Clearances

Safety Wheel Clearances define the clearance amount around the wheel when the wheel approaches the dresser diamonds. They can also be used to make the diamond dress passed the edge of the wheel to ensure a clean dress.

Delta X is in diameter mode, so 0.050" would only leave a 0.025" gap between the wheel and the diamond.

Wheel Return Clearances

Wheel Return Clearances define the amount the wheel will back off the part when returning from a dress cycle. This is to make sure the wheel doesn't come in too hard on the part after dressing mid cycle.

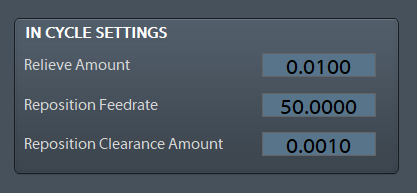

In Cycle Settings

- Relieve Amount is the distance the wheel will move away from the last grind in the Relieve G289 Cycle.

- Reposition Feedrate is used in cycles that need to reposition the wheel mid cycle.

- Reposition Clearance Amount is used in the Multiple Plunge Grind cycle when returning the wheel to the start position.

Dresser Setup

- Select the type of dresser that matches the machine. The most standard dresser is #1.

- If dressing a form or taper on a new wheel, enter the desired offsets in the "New Wheel Teach Offsets" box to shift the dress start positions.

- Using the Jog buttons or MPG, Jog the wheel so the circumference of the wheel is just touching the diamond in the X axis direction.

- Press the yellow TEACH button for X.

- Jog the wheel so the Face is just touching the diamond in the Z axis direction.

- Press the yellow TEACH button for Z.

If the dresser type is #2 or #3 then repeat steps 4-6 for each diamond.

- Select the “Tip Radius box, enter the radius size of the dresser point.

Rough Dress

After the dresser is setup a rough dress program needs to be run to true up the wheel before calibrating the wheel to the part. Use the Conversational to create a dress program that will profile and true the wheel. Re-run this program until the diamond touches all the way across the wheel.

See Dress Cycles to learn more about creating a dress program.

Calibrating the Wheel to the Part

Initial calibration of the wheel to the part must always be done if the dresser positions are modified!

X Calibration

- Mount a scrap part into the machine and turn on the Wheel Head and Work Head.

- Using the Jog buttons or MPG, Jog the wheel so the circumference of the wheel is just touching the part and then continue jogging until the wheel has trued up the part and is making contact all the way around.

- Press the yellow Teach X button and then jog off and away from the part to a safe distance.

- Stop the Work Head and Wheel Head.

- Using a precision measuring device, measure the diameter of the newly ground surface.

- Enter the diameter into the Measured X box and press enter.

- Press the orange Update button.

Z Calibration (With One Wheel)

- Mount a scrap part into the machine and turn on the Wheel Head and Work Head.

- Near the bottom of the page is the Tool Offsets group. Type "0.0" into the "Z Offset" and into the "Z Wear Offsets" boxes.

- Using the Jog buttons or MPG, Jog the wheel so the face of the wheel is just touching the shoulder of the part and then continue jogging until the wheel has trued up the shoulder and is making contact all the way around.

- Press the grey Zero Z button near the Z Position DRO.

Z Calibration (With Multiple Wheels)

Follow the "Z Calibration (With One Wheel)" steps on the master wheel.

- Mount a scrap part into the machine and turn on the Wheel Head and Work Head.

- Using the Jog buttons or MPG, Jog the wheel so the face of the wheel is just touching the shoulder of the part and then continue jogging until the wheel has trued up the shoulder and is making contact all the way around.

- Press the yellow Teach Z button and then jog off and away from the part to a safe distance.

- Stop the Work Head and Wheel Head.

- Using a precision measuring device measure the position of the shoulder of the newly ground surface.

- Enter the diameter into the Measured Z box and press enter.

- Press the orange Update button.

Use the X Correction and Z Correction fields to adjust the part positions by distance values and pressing Update

Calibrating the Flag to the Wheel

Calibration of the Flag must be done if the dresser positions are modified!

Calibrating the Flag will setup the Z offsets between the wheel Face #1 and the Flag probe. Calibration needs to be done anytime a wheel dresser is re-setup. You must calibrate the Flag to the same shoulder that was used to calibrate the Z side of the wheel the previous step. (Calibrating the Wheel to the Part)

Calibration Wizard

Follow the instructions on the calibration pages to calibrate the Flag to the wheel

Loading a Job to Run

Creating a New Conversational Job

Loading a Conversational Job for Edit

Flagging Device Initial Setup

- Jog the X and Z axis to a safe position for the flag to use as the Swivel Position and press the two yellow TEACH buttons.

- Enter the appropriate feedrate to be used on the initial search for the shoulder into the DRO labeled Fast Feedrate.

- Enter the appropriate feedrate to be used on the final search for the shoulder into the DRO labeled Slow Feedrate.

- Enter the appropriate distance for the probe to back away from the shoulder on the second touch into the DRO labeled Back-Off Distance.

- The Probe offsets Z+/- are used to shift the probe position +/- based on the probe move direction.

Grinding Cycles

Dressing Cycles

Angled Wheel Dressing

The control has two options for compensating the X and Z tool offsets while dressing a wheel that is mounted at an angle. Option 1 - Dress and compensate equal amounts on X and Z axes.

Option 2 - The Z Dress amount and compensation is calculated using the wheel Working Angle from the Wheel Head Setup page.

To use Option 1 copy the following GCode into MDI and run it.

G10 L50 (Start the parameter setting sequence)

N1915 R0 (Set parameter 1915 = 0)

G11 (End G10 sequence)To use Option 2 copy the following GCode into MDI and run it.

G10 L50 (Start the parameter setting sequence)

N1915 R1 (Set parameter 1915 = 1)

G11 (End G10 sequence)Positioning to Dress

When a dressing cycle is called the machine will always follow the following path from the part to the dresser, in order to avoid collisions with the part and the diamond.

G251: Dress Taper Face 1, Left

The G251 cycle dresses a taper on the left face. It can increment in on just the X axis, just the Z axis, or on both axes.

The size of the phase height, relief height, and relief angle are all set on the Wheel Head Setup page.

Parameters:

-

- D: The infeed increment to remove from the wheel on each pass.

- E: The number of passes to make across the wheel.

- F: The feedrate to use while dressing wheel.

- I: The height of the taper to put on the wheel (X direction).

- J: The angle of the taper to put on the wheel.

- K: The length of the taper to put on the wheel (Z direction).

- [M]: Passing in a 1 to the M parameter will force dressing. If the parameter is not given and the number of parts per dressing has not been met, then dressing will be skipped.

- [R]: Passing in a 1 to the R parameter will skip setting tool offsets and wheel sizes.

- [T]: The Z infeed increment to remove from the wheel on each pass.

- [Q]: Selects the compensation direction used during the dressing cycles. By default, the compensation is only in the X direction, changing the diameter of the wheel. If a 1 is passed to the Q parameter, then compensation will be in the Z direction, narrowing the wheel. If a 2 is passed to the Q parameter, then compensation will be in the X and Z directions, changing the diameter and narrowing the wheel.

Only two of the parameters I, J, K are required.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G251 D0.0003 F10 E4 I1.0 J45.0 (Wheel Dress)

M30 (End program)

% (EOB)G252: Dress Taper Face 2, Right

The G252 cycle dresses a taper on the right face. It can increment in on just the X axis, just the Z axis, or on both axes.

The size of the phase height, relief height, and relief angle are all set on the Wheel Head Setup page.

Parameters:

-

- D: The infeed increment to remove from the wheel on each pass.

- E: The number of passes to make across the wheel.

- F: The feedrate to use while dressing wheel.

- I: The height of the taper to put on the wheel (X direction).

- J: The angle of the taper to put on the wheel.

- K: The length of the taper to put on the wheel (Z direction).

- [M]: Passing in a 1 to the M parameter will force dressing. If the parameter is not given and the number of parts per dressing has not been met, then dressing will be skipped.

- [R]: Passing in a 1 to the R parameter will skip setting tool offsets and wheel sizes.

- [T]: The Z infeed increment to remove from the wheel on each pass.

- [Q]: Selects the compensation direction used during the dressing cycles. By default, the compensation is only in the X direction, changing the diameter of the wheel. If a 1 is passed to the Q parameter, then compensation will be in the Z direction, narrowing the wheel. If a 2 is passed to the Q parameter, then compensation will be in the X and Z directions, changing the diameter and narrowing the wheel.

Only two of the parameters I, J, K are required.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G252 D0.0003 F10 E4 I1.0 J45.0 (Wheel Dress)

M30 (End program)

% (EOB)G253: Dress Circumference and Taper Face 1, Left

The G253 cycle dresses the circumference of the wheel and puts a taper on the left face. It can increment in on just the X axis, just the Z axis, or on both axes.

The size of the phase height, relief height, and relief angle are all set on the Wheel Head Setup page.

Parameters:

-

- D: The infeed increment to remove from the wheel on each pass.

- E: The number of passes to make across the wheel.

- F: The feedrate to use while dressing wheel.

- I: The height of the taper to put on the wheel (X direction).

- J: The angle of the taper to put on the wheel.

- K: The length of the taper to put on the wheel (Z direction).

- [M]: Passing in a 1 to the M parameter will force dressing. If the parameter is not given and the number of parts per dressing has not been met, then dressing will be skipped.

- [R]: Passing in a 1 to the R parameter will skip setting tool offsets and wheel sizes.

- [T]: The Z infeed increment to remove from the wheel on each pass.

- [Q]: Selects the compensation direction used during the dressing cycles. By default, the compensation is only in the X direction, changing the diameter of the wheel. If a 1 is passed to the Q parameter, then compensation will be in the Z direction, narrowing the wheel. If a 2 is passed to the Q parameter, then compensation will be in the X and Z directions, changing the diameter and narrowing the wheel.

Only two of the parameters I, J, K are required.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G253 D0.0003 F10 E4 I1.0 J45.0 (Wheel Dress)

M30 (End program)

% (EOB)G254: Dress Circumference and Taper Face 2, Right

The G254 cycle dresses the circumference of the wheel and puts a taper on the right face. It can increment in on just the X axis, just the Z axis, or on both axes.

The size of the phase height, relief height, and relief angle are all set on the Wheel Head Setup page.

Parameters:

-

- D: The infeed increment to remove from the wheel on each pass.

- E: The number of passes to make across the wheel.

- F: The feedrate to use while dressing wheel.

- I: The height of the taper to put on the wheel (X direction).

- J: The angle of the taper to put on the wheel.

- K: The length of the taper to put on the wheel (Z direction).

- [M]: Passing in a 1 to the M parameter will force dressing. If the parameter is not given and the number of parts per dressing has not been met, then dressing will be skipped.

- [R]: Passing in a 1 to the R parameter will skip setting tool offsets and wheel sizes.

- [T]: The Z infeed increment to remove from the wheel on each pass.

- [Q]: Selects the compensation direction used during the dressing cycles. By default, the compensation is only in the X direction, changing the diameter of the wheel. If a 1 is passed to the Q parameter, then compensation will be in the Z direction, narrowing the wheel. If a 2 is passed to the Q parameter, then compensation will be in the X and Z directions, changing the diameter and narrowing the wheel.

Only two of the parameters I, J, K are required.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G254 D0.0003 F10 E4 I1.0 J45.0 (Wheel Dress)

M30 (End program)

% (EOB)G255: Dress Circumference, Taper, Face 1 and Face 2

The G255 cycle dresses the circumference of the wheel and puts a taper on both faces. It can increment in on just the X axis, just the Z axis, or on both axes.

The size of the phase height, relief height, and relief angle are all set on the Wheel Head Setup page.

Parameters:

-

- D: The infeed increment to remove from the wheel on each pass.

- E: The number of passes to make across the wheel.

- F: The feedrate to use while dressing wheel.

- I: The height of the taper to put on the wheel (X direction).

- J: The angle of the taper to put on the wheel.

- K: The length of the taper to put on the wheel (Z direction).

- [M]: Passing in a 1 to the M parameter will force dressing. If the parameter is not given and the number of parts per dressing has not been met, then dressing will be skipped.

- [R]: Passing in a 1 to the R parameter will skip setting tool offsets and wheel sizes.

- [T]: The Z infeed increment to remove from the wheel on each pass.

- [Q]: Selects the compensation direction used during the dressing cycles. By default, the compensation is only in the X direction, changing the diameter of the wheel. If a 1 is passed to the Q parameter, then compensation will be in the Z direction, narrowing the wheel. If a 2 is passed to the Q parameter, then compensation will be in the X and Z directions, changing the diameter and narrowing the wheel.

Only two of the parameters I, J, K are required.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G255 D0.0003 F10 E4 I1.0 J45.0 (Wheel Dress)

M30 (End program)

% (EOB)G260: Dress Circumference

The G260 cycle dresses along the circumference of the wheel, feeding in on the X axis towards the center of the wheel.

Parameters:

-

- D: The infeed increment to remove from the wheel on each pass.

- E: The number of passes to make across the wheel.

- F: The feedrate to use while dressing wheel.

- [M]: Passing in a 1 to the M parameter will force dressing. If the parameter is not given and the number of parts per dressing has not been met, then dressing will be skipped.

- [R]: Passing in a 3 to the R parameter will both skip setting tool offsets and wheel sizes, AND not return the wheel to the part after the dress cycle.

-

- Passing in a 1 to the R parameter will skip setting tool offsets and wheel sizes.

- Passing in a 2 to the R parameter will not return the wheel to the part after the dress cycle.

-

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G260 D0.0003 F10 E4 (Wheel Dress)

M30 (End program)

% (EOB)G261: Dress Face 1, Left

The G261 cycle dresses along the left face of the wheel, feeding in on the Z axis towards the center of the wheel.

The size of the phase height, relief height, and relief angle are all set on the Wheel Head Setup page.

Parameters:

- D: The infeed increment to remove from the wheel on each pass.

- E: The number of passes to make across the wheel.

- F: The feedrate to use while dressing wheel.

- [M]: Passing in a 1 to the M parameter will force dressing. If the parameter is not given and the number of parts per dressing has not been met, then dressing will be skipped.

- [R]: Passing in a 3 to the R parameter will both skip setting tool offsets and wheel sizes, AND not return the wheel to the part after the dress cycle.

-

- Passing in a 1 to the R parameter will skip setting tool offsets and wheel sizes.

- Passing in a 2 to the R parameter will not return the wheel to the part after the dress cycle.

-

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G261 D0.0003 F10 E4 (Wheel Dress)

M30 (End program)

% (EOB)G262: Dress Face 2, Right

The G262 cycle dresses along the right face of the wheel, feeding in on the Z axis towards the center of the wheel.

The size of the phase height, relief height, and relief angle are all set on the Wheel Head Setup page.

Parameters:

- D: The infeed increment to remove from the wheel on each pass.

- E: The number of passes to make across the wheel.

- F: The feedrate to use while dressing wheel.

- [M]: Passing in a 1 to the M parameter will force dressing. If the parameter is not given and the number of parts per dressing has not been met, then dressing will be skipped.

- [R]: Passing in a 3 to the R parameter will both skip setting tool offsets and wheel sizes, AND not return the wheel to the part after the dress cycle.

-

- Passing in a 1 to the R parameter will skip setting tool offsets and wheel sizes.

- Passing in a 2 to the R parameter will not return the wheel to the part after the dress cycle.

-

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G262 D0.0003 F10 E4 (Wheel Dress)

M30 (End program)

% (EOB)G263: Dress Circumference and Face 1, Left

The G263 dressing cycle dresses along the circumference of the wheel and the left face. It can increment in on just the X axis, just the Z axis, or on both axes.

The size of the corner radius, phase height, relief height, and relief angle are all set on the Wheel Head Setup page.

Parameters:

-

- D: The infeed increment to remove from the wheel on each pass.

- F: The feedrate to use while dressing wheel.

- E: The number of passes to make across the wheel.

- [M]: Passing in a 1 to the M parameter will force dressing. If the parameter is not given and the number of parts per dressing has not been met, then dressing will be skipped.

- [R]: Passing in a 3 to the R parameter will both skip setting tool offsets and wheel sizes, AND not return the wheel to the part after the dress cycle.

-

- Passing in a 1 to the R parameter will skip setting tool offsets and wheel sizes.

- Passing in a 2 to the R parameter will not return the wheel to the part after the dress cycle.

-

- [T]: The Z infeed increment to remove from the wheel on each pass.

- [Q]: Selects the compensation direction used during the dressing cycles. By default, the compensation is only in the X direction, changing the diameter of the wheel. If a 1 is passed to the Q parameter, then compensation will be in the Z direction, narrowing the wheel. If a 2 is passed to the Q parameter, then compensation will be in the X and Z directions, changing the diameter and narrowing the wheel.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G263 D0.0003 F10 E4 (Wheel Dress)

M30 (End program)

% (EOB)G264: Dress Circumference and Face 2, Right

The G264 dressing cycle dresses along the circumference of the wheel and the right face. It can increment in on just the X axis, just the Z axis, or on both axes.

The size of the corner radius, phase height, relief height, and relief angle are all set on the Wheel Head Setup page.

Parameters:

-

- D: The infeed increment to remove from the wheel on each pass.

- F: The feedrate to use while dressing wheel.

- E: The number of passes to make across the wheel.

- [M]: Passing in a 1 to the M parameter will force dressing. If the parameter is not given and the number of parts per dressing has not been met, then dressing will be skipped.

- [R]: Passing in a 3 to the R parameter will both skip setting tool offsets and wheel sizes, AND not return the wheel to the part after the dress cycle.

-

- Passing in a 1 to the R parameter will skip setting tool offsets and wheel sizes.

- Passing in a 2 to the R parameter will not return the wheel to the part after the dress cycle.

-

- [T]: The Z infeed increment to remove from the wheel on each pass.

- [Q]: Selects the compensation direction used during the dressing cycles. By default, the compensation is only in the X direction, changing the diameter of the wheel. If a 1 is passed to the Q parameter, then compensation will be in the Z direction, narrowing the wheel. If a 2 is passed to the Q parameter, then compensation will be in the X and Z directions, changing the diameter and narrowing the wheel.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G264 D0.0003 F10 E4 (Wheel Dress)

M30 (End program)

% (EOB)G266: Roll (Crush) Dressing

The G266 roll dressing cycle brings the wheel to the start position and then increments into the diamond by set amounts. Between each infeed, there is an optional dwell time.

Parameters:

-

- D: Infeed increment amount to feed into the wheel on each pass

- E: The number of passes to make across the wheel.

- F: The feedrate to dress at while feeding into the diamond.

- [H]: The amount of time to dwell between each infeed, in seconds. Defaults to 0.

- [M]: Dressing may be skipped if the number of parts made since last dress has not met the required number. In order to force dressing, pass in a 1 to the M parameter.

- [R]: Passing in a 3 to the R parameter will both skip setting tool offsets and wheel sizes, AND not return the wheel to the part after the dress cycle.

-

- Passing in a 1 to the R parameter will skip setting tool offsets and wheel sizes.

- Passing in a 2 to the R parameter will not return the wheel to the part after the dress cycle.

-

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G266 D0.0003 F10 E2 (Wheel Dress)

M30 (End program)

% (EOB)G269: Profile Dressing

The G269 profile dressing cycle runs a profile routine written by an operator. It will increment in a given number of times and repeatedly run the same profile.

Parameters:

-

- D: Infeed increment amount to feed into the wheel on each pass.

- E: The number of passes to make across the wheel.

- F: The feedrate to dress at while feeding into the diamond.

- K: The program number to run to cut the profile.

- [M]: Passing in a 1 to the M parameter will force dressing. If the parameter is not given and the number of parts per dressing has not been met, then dressing will be skipped.

- [R]: Passing in a 3 to the R parameter will both skip setting tool offsets and wheel sizes, AND not return the wheel to the part after the dress cycle.

-

- Passing in a 1 to the R parameter will skip setting tool offsets and wheel sizes.

- Passing in a 2 to the R parameter will not return the wheel to the part after the dress cycle.

-

- [T]: The Z infeed increment to remove from the wheel on each pass.

- [Q]: Selects the compensation direction used during the dressing cycles. By default, the compensation is only in the X direction, changing the diameter of the wheel. If a 1 is passed to the Q parameter, then compensation will be in the Z direction, narrowing the wheel. If a 2 is passed to the Q parameter, then compensation will be in the X and Z directions, changing the diameter and narrowing the wheel.

Grinding Cycles

G200: Rapid to Safety Positions

G200 commands a return to the safety positions. The safety positions are configured machine coordinates that can be set on safety page.

Parameters:

-

- E: Safety position selection

- E1: Part safety position

- E2: Dresser safety position

- E: Safety position selection

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety positions)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X2.050 Z0.000 F10.000 H1.000 (Swing Position 1 Definition, Left)

G272 R3.000 F20.000 H2.000 (Swing Position 2 Definition, Right)

G288 (Handwheel Infeed Cycle)

G200 E1 (Move to part safety position)

M30 (Program Rewind)

% (EOB)G271: Approach Swing Position 1, Left

G271 and G272 collectively define a section of the work piece for grinding. They define the swing positions, swing feedrates, and dwell times to be used for any applicable cycles that are called in the program afterwards. Both G271 and G272 must be called in the program before the following cycles can be used:

Parameters:

-

- X: The starting diameter, in part coordinates, for all applicable cycles.

- Z: The left swing position in part coordinates of the section being defined.

- [E]: The Part Correction Offset number (0-99). Applies a correction to X and Z axes. This is used to make small corrections to the different diameters or shoulders on the part.

- F: The feedrate used while feeding towards swing position 2 (right).

- [H]: The time, in seconds, the machine will dwell after reaching the defined position. If unspecified, the value will default to 0.

- [U]: X Clearance position in diameter. The machine will rapid to this value away from the [X]: starting diameter

- before moving at feedrate from there to the [X]: starting diameter. Value can be negative.

- [V]: Z Clearance position. The machine will rapid to this value away from the [Z]: starting position before moving at feedrate from there to the [Z]: starting position. Value can be negative.

- [W]: Z offset

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety positions)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X2.050 Z0.000 F10.000 H1.000 (Swing Position 1 Definition, Left)

G272 R3.000 F20.000 H2.000 (Swing Position 2 Definition, Right)

G288 (Handwheel Infeed Cycle)

G200 E1 (Move to safety positions)

M30 (Program Rewind)

% (EOB)If either G271 or G272 are not specified in the program before the applicable cycles, the machine will enter an alarm state and the program will be stopped.

G272: Approach Swing Position 2, Right

G271 and G272 collectively define a section of the work piece for grinding. They define the swing positions, swing feedrates, and dwell times to be used for any applicable cycles that are called in the program afterwards. Both G271 and G272 must be called in the program before the following cycles can be used:

Parameters:

-

- R: The distance between the P1 and P2 positions. This value must be greater than the wheel width.

- F: The feedrate used while feeding towards the defined position.

- [H]: The time, in seconds, the machine will dwell after reaching the defined position. If unspecified, the value will default to 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety positions)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X2.050 Z0.000 F10.000 H1.000 (Swing Position 1 Definition, Left)

G272 R3.000 F20.000 H2.000 (Swing Position 2 Definition, Right)

G288 (Handwheel Infeed Cycle)

G200 E1 (Move to safety positions)

M30 (Program Rewind)

% (EOB)If either G271 or G272 are not specified in the program before the applicable cycles, the machine will enter an alarm state and the program will be stopped.

G241: Roll Grind with Infeed at Swing Position 1, Left

G241 does a traverse roll grind between the positions defined in G271 and G272 while infeeding the wheel incrementally by a defined infeed amount each time the wheel reaches swing position 1 (left), until the diameter defined by the finish diameter plus allowance amount has been reached, at which point a specified number of spark passes will happen.

Parameters:

-

- D: The infeed increment that X axis feeds in by each time the Z axis reaches swing position 1, left

- X: The final diameter to grind to during this cycle

- F: The feedrate to feed in at the X axis

- R: The arc height for the crown in the roll also referred in geometry as the Sagitta

- [A]: The allowance to leave on the final grind diameter. Defaults to 0.

- [H]: The number of spark passes to do after the grind completes. Default is 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety position)

G260 D0.0003 F10 E2 (Wheel Dress before rough grind)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X 1.010 Z0.0 F10 (Define left start position and rapid to position)

G272 R3.5 F10 (Define traverse distance between left and right side of wheel)

G274 X1.0 A.001 W75 H2 (Multi-step plunge grind. Target position X, Allowance A, Step over percent W, Dwell H)

G260 D0.0003 F10 E2 (Wheel Dress before finish grind)

G241 X1.0 A0.0 D0.0001 H2 R0.005 (Target position X, Allowance A, Infeed D, Sparkouts H, Arc Height R)

G280 (End macro)

G200 E1 (Move to safety position)

M30 (End program)

% (EOB)G242: Roll Grind with Infeed at Swing Position 2, Right

G242 does a traverse roll grind between the positions defined in G271 and G272 while infeeding the wheel incrementally by a defined infeed amount each time the wheel reaches swing position 2 (right), until the diameter defined by the finish diameter plus allowance amount has been reached, at which point a specified number of spark passes will happen.

Parameters:

-

- D: The infeed increment that X axis feeds in by each time the Z axis reaches swing position 2, right

- X: The final diameter to grind to during this cycle

- F: The feedrate to feed in at the X axis

- R: The arc height for the crown in the roll also referred in geometry as the Sagitta

- [A]: The allowance to leave on the final grind diameter. Defaults to 0.

- [H]: The number of spark passes to do after the grind completes. Default is 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety position)

G260 D0.0003 F10 E2 (Wheel Dress before rough grind)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X 1.010 Z0.0 F10 (Define left start position and rapid to position)

G272 R3.5 F10 (Define traverse distance between left and right side of wheel)

G274 X1.0 A.001 W75 H2 (Multi-step plunge grind. Target position X, Allowance A, Step over percent W, Dwell H)

G260 D0.0003 F10 E2 (Wheel Dress before finish grind)

G242 X1.0 A0.0 D0.0001 H2 R0.005 (Target position X, Allowance A, Infeed D, Sparkouts H, Arc Height R)

G280 (End macro)

G200 E1 (Move to safety position)

M30 (End program)

% (EOB)G244: Roll Grind with Infeed at Both Swing Positions

G244 does a traverse roll grind between the positions defined in G271 and G272 while infeeding the wheel incrementally by a defined infeed amount at each swing position, until the diameter defined by the finish diameter plus allowance amount has been reached, at which point a specified number of spark passes will happen.

Parameters:

-

- D: The infeed increment that X axis feeds in by each time the Z axis reaches a swing position

- X: The final diameter to grind to during this cycle

- F: The feedrate to feed in at the X axis

- R: The arc height for the crown in the roll also referred in geometry as the Sagitta

- [A]: The allowance to leave on the final grind diameter. Defaults to 0.

- [H]: The number of spark passes to do after the grind completes. Default is 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety position)

G260 D0.0003 F10 E2 (Wheel Dress before rough grind)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X 1.010 Z0.0 F10 (Define left start position and rapid to position)

G272 R3.5 F10 (Define traverse distance between left and right side of wheel)

G274 X1.0 A0.001 W75 H2 (Multi-step plunge grind. Target position X, Allowance A, Step over percent W, Dwell H)

G260 D0.0003 F10 E2 (Wheel Dress before finish grind)

G244 X1.0 A0.0 D0.0001 H2 R0.005 (Target position X, Allowance A, Infeed D, Sparkouts H, Arc Height R)

G280 (End macro)

G200 E1 (Move to safety position)

M30 (End program)

% (EOB)G273: Approach Oscillating Position

G273 is used in conjunction with G283 for grinding narrower features. When Invoked, the wheel will rapid to the X and Z start positions and set the oscillation stroke, which is the distance specified in parameter "D". The Z oscillation will move from the start position to the end position in the positive direction.

Parameters:

- X: X start position

- Z: Z start position

- D: Oscillation stroke distance

- [E]: The Part Correction Offset number (0-99). Applies a correction to X and Z axes. This is used to make small corrections to the different diameters or shoulders on the part.

- [F]: Traverse feedrate

- [H]: Number of spark passes

- [U]: X Clearance position in diameter. The machine will rapid to this value away from the [X]: starting diameter

- before moving at feedrate from there to the [X]: starting diameter. Value can be negative.

- [V]: Z Clearance position. The machine will rapid to this value away from the [Z]: starting position before moving at feedrate from there to the [Z]: starting position. Value can be negative.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety positions)

M3 S100 (Workhead on CW @ 100 RPM)

G273 X2.050 Z-2.000 D1.000 (Oscillation Position Definition)

G283 X2.000 D0.005 F0.100 H1.000 (Continuous Infeed Cycle)

G200 E1 (Move to safety positions)

M30 (Program Rewind)

% (EOB)G274: Multiple Plunge Grind

G274 does a set of plunge grinds between the positions defined in G271 and G272, moving the wheel over by a percentage of the wheel width for each plunge. The plunge amount is the diameter defined by the finish diameter plus the allowance amount. Each plunge can have a dwell at the bottom for a specified number of seconds.

Parameters:

-

- X: The final diameter to grind to in this cycle.

- [A]: The allowance to leave on the final grind diameter. Defaults to 0.

- [W]: The percent of wheel to step over on each plunge. Defaults to 90.

- F: The feedrate to plunge in on the X axis.

- [H]: The amount of time to dwell after each plunge completes. Default is 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety position)

G260 D0.0003 F10 E2 (Wheel Dress before rough grind)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X1.010 Z0.0 F10 (Define left start position and rapid to position)

G272 R3.5 F10 (Define traverse distance between left and right side of wheel)

G274 X1.0 A.001 W75 H2 (Multi-step plunge grind. Target position X, Allowance A, Step over percent W, Dwell H)

G260 D0.0003 F10 E2 (Wheel Dress before finish grind)

G281 X1.0 A0.0 D0.0001 H2 (Target position X, Allowance A, Infeed D, Sparkouts H)

G280 (End macro)

G200 E1 (Move to safety position)

M30 (End program)

% (EOB)G276: Approach Plunge Position

G276 sets the starting position for any following G287 plunge cycles and moves into position, as Z axis then X axis.

Parameters:

-

- X: Defines the starting X diameter for subsequent plunge cycles

- Z: Defines the starting Z position for subsequent plunge cycles

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety position)

G260 D0.0003 F10 E2 (Wheel Dress before rough grind)

M3 S100 (Workhead on CW @ 100 RPM)

G276 X1.010 Z0.0 (Define plunge grind start position and rapid to position)

G287 X1.0 Z-0.02 F0.001 H2 (Target position X, Target position Z, Feedrate F, Sparkout time H)

G280 (End macro)

G200 E1 (Move to safety position)

M30 (End program)

% (EOB)G277: Approach Face Grind Position

G277 is used in conjunction with G291 and G293 for face grinding with the side of the wheel. When Invoked, the wheel will rapid to the X P1 and Z start position and store the X P2 along with the traverse feedrate and dwell time.

Parameters:

- X: X start position P1

- Z: Z start position

- R: X finish position P2

- [E]: The Part Correction Offset number (0-99). Applies a correction to X and Z axes. This is used to make small corrections to the different diameters or shoulders on the part.

- [F]: Traverse feedrate on X- while moving to P2 position

- [H]: Traverse dwell time in seconds

- [Q]: Traverse feedrate on X+ while moving to P1 position

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety position)

G260 D0.0003 F10 E2 (Wheel Dress before rough grind)

M3 S100 (Workhead on CW @ 100 RPM)

G277 X4.0 Z0.0 R2.0 H1.0 F25.0 (Define face grind start position and rapid to position)

G293 Z-0.1 A0.005 U0.25 F0.01 H1.5 (Target position Z, Z Stock Allowance A, X Step Size U, Feedrate F, Sparkout time H)

G280 (End macro)

G200 E1 (Move to safety position)

M30 (End program)

% (EOB)G280: End of Grind Cycle

G280 will reset the dressing flag and clears grinding data.

G281: Traverse Grind with Infeed at Swing Position 1, Left

G281 does a traverse grind between the positions defined in G271 and G272 while infeeding the wheel incrementally by a defined infeed amount each time the wheel reaches swing position 1 (left), until the diameter defined by the finish diameter plus allowance amount has been reached, at which point a specified number of spark passes will happen.

Parameters:

-

- D: The infeed increment that X axis feeds in by each time the Z axis reaches swing position 1, left

- X: The final diameter to grind to during this cycle

- F: The feedrate to feed in at the X axis

- [A]: The allowance to leave on the final grind diameter. Defaults to 0.

- [H]: The number of spark passes to do after the grind completes. Default is 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety position)

G260 D0.0003 F10 E2 (Wheel Dress before rough grind)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X 1.010 Z0.0 F10 (Define left start position and rapid to position)

G272 R3.5 F10 (Define traverse distance between left and right side of wheel)

G274 X1.0 A.001 W75 H2 (Multi-step plunge grind. Target position X, Allowance A, Step over percent W, Dwell H)

G260 D0.0003 F10 E2 (Wheel Dress before finish grind)

G281 X1.0 A0.0 D0.0001 H2 (Target position X, Allowance A, Infeed D, Sparkouts H)

G280 (End macro)

G200 E1 (Move to safety position)

M30 (End program)

% (EOB)G282: Traverse Grind with Infeed at Swing Position 2, Right

G282 does a traverse grind between the positions defined in G271 and G272 while infeeding the wheel incrementally by a defined infeed amount each time the wheel reaches swing position 2 (right), until the diameter defined by the finish diameter plus allowance amount has been reached, at which point a specified number of spark passes will happen.

Parameters:

-

- D: The infeed increment that X axis feeds in by each time the Z axis reaches swing position 2, right

- X: The final diameter to grind to during this cycle

- F: The feedrate to feed in at the X axis

- [A]: The allowance to leave on the final grind diameter. Defaults to 0.

- [H]: The number of spark passes to do after the grind completes. Default is 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety position)

G260 D0.0003 F10 E2 (Wheel Dress before rough grind)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X 1.010 Z0.0 F10 (Define left start position and rapid to position)

G272 R3.5 F10 (Define traverse distance between left and right side of wheel)

G274 X1.0 A.001 W75 H2 (Multi-step plunge grind. Target position X, Allowance A, Step over percent W, Dwell H)

G260 D0.0003 F10 E2 (Wheel Dress before finish grind)

G282 X1.0 A0.0 D0.0001 H2 (Target position X, Allowance A, Infeed D, Sparkouts H)

G280 (End macro)

G200 E1 (Move to safety position)

M30 (End program)

% (EOB)G283: Continuous Infeed Grind

G283 is used in conjunction with G273 for grinding narrower features. When invoked, the wheel will rapid to the X and Z start positions and set the oscillation stroke defined with G273. The wheel will then feed in the specified "D" distance in X while traversing in each Z direction.

Parameters:

-

- X: The final diameter to grind to during this cycle

- D: The infeed increment that X axis feeds in by on each pass

- [A]: The allowance to leave on the final grind diameter. Defaults to 0.

- F: The feedrate to move at during this cycle

- [H]: The number of spark passes to do after the grind completes. Default is 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety positions)

M3 S100 (Workhead on CW @ 100 RPM)

G273 X2.050 Z-2.000 D0.200 H1.000 (Oscillation Position Definition, Left)

G283 X2.000 D0.005 F10.000 (Continuous Infeed Cycle)

G200 E1 (Move to safety positions)

M30 (Program Rewind)

% (EOB)G284: Traverse Grind with Infeed at Both Swing Positions

G284 does a traverse grind between the positions defined in G271 and G272 while infeeding the wheel incrementally by a defined infeed amount at each swing position, until the diameter defined by the finish diameter plus allowance amount has been reached, at which point a specified number of spark passes will happen.

Parameters:

-

- D: The infeed increment that X axis feeds in by each time the Z axis reaches a swing position

- X: The final diameter to grind to during this cycle

- F: The feedrate to feed in at the X axis

- [A]: The allowance to leave on the final grind diameter. Defaults to 0.

- [H]: The number of spark passes to do after the grind completes. Default is 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety position)

G260 D0.0003 F10 E2 (Wheel Dress before rough grind)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X 1.010 Z0.0 F10 (Define left start position and rapid to position)

G272 R3.5 F10 (Define traverse distance between left and right side of wheel)

G274 X1.0 A0.001 W75 H2 (Multi-step plunge grind. Target position X, Allowance A, Step over percent W, Dwell H)

G260 D0.0003 F10 E2 (Wheel Dress before finish grind)

G284 X1.0 A0.0 D0.0001 H2 (Target position X, Allowance A, Infeed D, Sparkouts H)

G280 (End macro)

G200 E1 (Move to safety position)

M30 (End program)

% (EOB)G285: Shoulder Grind at Swing Position 1, Left

G285 works with G271 and G272 or G273. G285 does a shoulder grind in the negative Z direction, starting from swing position 1, left. This means it will move outside of the area defined by G271 and G272. G285 will grind to a defined Z position, leaving space for an optional stock allowance.

Parameters:

-

- Z: The Z target position to grind to.

- [X]: The X Start Diameter to rapid X to before grinding in the Z direction.

- D: Feedrate to move the Z axis at.

- [A]: The allowance to leave on the final grind position. Defaults to 0.

- [H]: The amount of spark out time once final grind position is reached. Defaults to 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety positions)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X2.050 Z0.000 F10.000 H1.000 (Swing Position 1 Definition, Left)

G272 R3.000 F20.000 H2.000 (Swing Position 2 Definition, Right)

G285 Z-1.000 D0.005 (Left Shoulder Grind Cycle)

G200 E1 (Move to safety positions)

M30 (Program Rewind)

% (EOB)G286: Shoulder Grind at Swing Position 2, Right

G286 works with G271 and G272 or G273. G286 does a shoulder grind in the positive Z direction, starting from swing position 2, right. This means it will move outside of the area defined by G271 and G272. G286 will grind to a defined Z position, leaving space for an optional stock allowance.

Parameters:

-

- Z: The Z target position to grind to.

- [X]: The diameter to rapid X to before grinding in the Z direction.

- D: Feedrate to move the Z axis at.

- [A]: The allowance to leave on the final grind position. Defaults to 0.

- [H]: The amount of spark out time once final grind position is reached. Defaults to 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety positions)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X2.050 Z0.000 F10.000 H1.000 (Swing Position 1 Definition, Left)

G272 R3.000 F20.000 H2.000 (Swing Position 2 Definition, Right)

G286 Z4.000 D0.005 (Right Shoulder Grind Cycle)

G200 E1 (Move to safety positions)

M30 (Program Rewind)

% (EOB)G287: Plunge Infeed Grind

G287 is used in conjunction with G276 for two axis plunge grinding. G276 defines the start point of the grind and G287 defines the ending position of the plunge grind.

Parameters:

-

- [X]: The final X diameter to plunge to

- [Z]: The final Z position to plunge to

- [A]: The allowance to leave on final grind position in both X and Z axes. Default is 0.

- F: The feedrate to plunge grind at.

- [H]: The amount of time to dwell after reaching plunge depth. Defaults to 0.

At least one of X or Z must be called in the cycle, if not both axes.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety position)

G260 D0.0003 F10 E2 (Wheel Dress before rough grind)

M3 S100 (Workhead on CW @ 100 RPM)

G276 X1.010 Z0.0 (Define plunge grind start position and rapid to position)

G287 X1.0 Z-0.02 F0.001 H2 (Target position X, Target position Z, Feedrate F, Sparkout time H)

G280 (End macro)

G200 E1 (Move to safety position)

M30 (End program)

% (EOB)G288: Handwheel Infeed Cycle

This cycle allows the operator to manually jog the X axis with the MPG handwheel or operator panel while the Z axis maintains the motion defined by G271 and G272. The cycle will continue until the operator presses Cycle Start or stops the program. Jogging on all axes other than X will be disabled during this cycle. There are no parameters for this cycle.

Upon pressing Cycle Start, the operator will be presented with a confirmation dialog on the control screen that they wish to end the handwheel infeed cycle. If they select 'No', the cycle will continue until they choose to end it again. If they select 'Yes', then the Z axis will continue its cycling until it reaches swing position 1, defined by G271, and then the main program will continue. While the axis is returning to swing position 1, a progress dialog will be displayed on the control screen.

If the operator presses Feedhold during the handwheel cycle, the Z axis will continue until it reaches the next swing position, and then stop there until Cycle Start is pressed or the program is stopped.

If the operator presses Cycle Stop while this cycle is running, the Z axis will stop without returning to either swing position. To control the distance that the axis takes to stop, set the parameter in MachMotion Configuration for Reciprocating Axis - Z Axis - Cycle Stop Distance.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety positions)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X2.050 Z0.000 F10.000 H1.000 (Swing Position 1 Definition, Left)

G272 R3.000 F20.000 H2.000 (Swing Position 2 Definition, Right)

G288 (Handwheel Infeed Cycle)

G200 E1 (Move to safety positions)

M30 (Program Rewind)

% (EOB)G289: Relieve

G289 performs a retract in X and Z axes. The cycle preceding G289 determines which axis and the direction of the retract. If G289 follows G281, G282, G283, G284, or G288, then the retract will be a positive X axis move. If G289 follows G285, then the retract will be a positive Z axis move. If G289 follows G286, then the retract will be a negative X axis move.

Parameters:

<>

-

- [W]: Relieve amount (Defaults to 0.01)

- [F]: Feedrate

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety positions)

M3 S100 (Workhead on CW @ 100 RPM)

G271 X2.050 Z0.000 F10.000 H1.000 (Swing Position 1 Definition, Left)

G272 R3.000 F20.000 H2.000 (Swing Position 2 Definition, Right)

G288 (Handwheel Infeed Cycle)

G289 (Retract)

M30 (Program Rewind)

% (EOB)G291: Traverse Infeed Face Grind

G291 works with G277. G291 does a traverse grind starting from X P1 (larger OD) to X P2. The wheel will plunge in on the Z axis each time the X axis reaches to X P1. G291 will grind to a defined Z position, leaving space for an optional stock allowance.

Parameters:

-

- Z: The Z target position to grind to.

- D: The infeed increment that Z axis feeds in by each time the X axis reaches a X P1.

- [A]: The allowance to leave on the final grind position. Defaults to 0.

- F: The feedrate to plunge grind at.

- [H]: The number of spark passes to do after the grind completes. Default is 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety position)

G260 D0.0003 F10 E2 (Wheel Dress before rough grind)

M3 S100 (Workhead on CW @ 100 RPM)

G277 X4.0 Z0.0 R2.0 H1.0 F25.0 (Define face grind start position and rapid to position)

G291 Z-0.1 A0.005 D0.002 F0.01 H1.0 (Target position Z, Z Stock Allowance A, Amount to per pass D, Feedrate F, Sparkout passes H)

G280 (End macro)

G200 E1 (Move to safety position)

M30 (End program)

% (EOB)G293: Multiple Plunge Face Grind

G293 works with G277. G293 does a multiple plunge grind starting from X P1 (larger OD) to X P2. The wheel will plunge in on the Z axis retract and move X in the step-over amount. G293 will grind to a defined Z position, leaving space for an optional stock allowance.

Parameters:

-

- Z: The Z target position to grind to.

- U: The X step-over amount.

- [A]: The allowance to leave on the final grind position. Defaults to 0.

- F: The feedrate to plunge grind at.

- [H]: The amount of time to dwell after reaching plunge depth. Defaults to 0.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

G200 E1 (Move to safety position)

G260 D0.0003 F10 E2 (Wheel Dress before rough grind)

M3 S100 (Workhead on CW @ 100 RPM)

G277 X4.0 Z0.0 R2.0 H1.0 F25.0 (Define face grind start position and rapid to position)

G293 Z-0.1 A0.005 U0.25 F0.01 H1.5 (Target position Z, Z Stock Allowance A, X Step Size U, Feedrate F, Sparkout time H)

G280 (End macro)

G200 E1 (Move to safety position)

M30 (End program)

% (EOB)Measuring Cycles

G230: Active Flagging with Probe

Flagging is used to find a shoulder on the part. When G230 is called the X axis will move to the X swivel position followed by the Z axis. The flagging slide will extend and then the Z axis will move to the Z start position followed by the X axis. The probing cycle will start with the Z axis moving at the calibrated fast feedrate. When the shoulder is detected, the probe will back off and probe again at the calibrated slow feedrate. The K parameter will be written to the current fixture offset (which defaults to G54) and the fixture table will be saved. The probe will move back to the start position, then back to the swivel position, and then retract.

Parameters:

-

- X: The start position X will rapid to before starting the flagging routine, after flag is extended.

- Z: The start position Z will rapid to before starting the flagging routine, after flag is extended.

- W: The distance Z will move searching for a shoulder, which can be positive or negative to indicate direction of travel.

- [E]: Selects between flagging the part and calibrating the probe. E1 will calibrate the probe. Defaults to 0 for normal flagging.

- [K]: The Z position used to calibrate the shoulder. Default is 0.

- [R]: Indicates if to retract the probe at the end of cycle. A value of 1 will leave the probe extended at the end of the cycle. Default is 0 to retract the probe.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G18 G20 (Safe Start Line)

T0101 (Call wheel type)

M5 (Workhead off)

G230 X2.0 Z0.2 W-1.0 K0.0 (Active Flagging Cycle)

M30 (Program Rewind)

% (EOB)When the flagging device is extended the X and Z axis reference switches from the wheel to the probe tip.

Path to swivel position and extend flagging probe:

Path to part from swivel position:

Flagging move from X and Z start position:

G232: Recalibration Cycle

Recalibration is typically used for setting the axes to a desired value after in-process gauging (auto-sizing). In the course of the recalibration, the current value of an axis is set to the value given in a macro. In this way,

the difference between the current axis value and the parameter-defined value will be added to the last active zero-point offset.

Parameters:

- X: The Position X will be set to.

- Z: The Position Z will be set to.

- [E]: If E1 is programmed the calibration will be local (valid only for the current grinding wheel), otherwise it will be global (effective for all the wheels)

M170: Wheel Head On

M170 will turn on the current Wheel Head and wait for the Wheel Head On Input

Parameters:

- S: Commanded Wheel Speed (Optional)

M171: Wheel Head Off

M171 will turn off the current Wheel Head

M172: Rotary Dresser On

M172 will turn on the Rotary Dresser and wait for the Wheel Head On Input

Parameters:

- S: Commanded Rotary Dresser Speed (Optional)

M173: Rotary Dresser Off

M173 will turn off the current Wheel Head

M239: Write to Tool Table

With M239 you can write to any value in the tool table using the names from the Wheel Head Memory table below.

Parameters:

- T: The value to write to the Tool Table

- Comment: (Data:"NameOfField")

Changing Wheel RPM in a program

M239 T1150 (Data:"CommandedRPM") would write to the tool table field named CommandedRPM and set the value to 1150.

Example:

G00 G40 G54 G64 G80 G90.1 G98 G18 G18 G20 (Safe Start Line)

M239 T1150 (Set the Commanded Wheel RPM to 1150 Data:"CommandedRPM")

% (EOB)Appendix

Cycle States

| 0 | Idle |

| 1 | Positioning |

| 2 | Spark-out |

| 3 | Finished |

| 4 | Free Pass |

| 100 | Grinding |

| 101 | Positioning |

| 102 | Spark-out |

| 103 | Finished |

| 104 | Free Pass |

| 105 | Moving to Grind Position |

| 106 | Gap Control Grinding |

| 200 | Dressing |

| 201 | Positioning |

| 202 | Spark-out |

| 203 | Finished |

| 204 | Free Pass |

| 205 | Moving to Dress Position |

| 206 | Returning from Dress Position |

| 207 | Gap Control Dressing |

Wheel Head Memory

| Pound Variable | Description | Tool Table Name | Tool Table Description |

| #9000 | Diameter | Diameter | Diameter (D) |

| #9001 | Effective Width | EffectiveWidth | Effective Width (B) |

| #9002 | Overhang | Overhang | Overhang (L) |

| #9003 | Minimum Diameter | MinimumDiameter | Minimum Diameter |

| #9004 | Minimum Width | MinimumWidth | Minimum Width |

| #9005 | Working Angle | WorkingAngle | Working Angle |

| #9006 | Corner Radius Left | CornerRadiusLeft | Corner Radius Left |

| #9007 | Relief Angle Left | ReliefAngleLeft | Relief Angle Left |

| #9008 | Relief Height Left | ReliefHeightLeft | Relief Height Left |

| #9009 | Corner Radius Right | CornerRadiusRight | Corner Radius Right |

| #9010 | Relief Angle Right | ReliefAngleRight | Relief Angle Right |

| #9011 | Relief Height Right | ReliefHeightRight | Relief Height Right |

| #9012 | Phase Height Left | PhaseHeightLeft | Phase Height Left |

| #9013 | Phase Height Right | PhaseHeightRight | Phase Height Right |

| #9014 | Max Wheel RPM | MaxRPM | Max Wheel RPM |

| #9015 | Wheel SFM | SurfaceFeetPerMin | Wheel SFM |

| #9016 | Wheel RPM | CommandedRPM | Wheel RPM |

| #9017 | Dresser Diamond Type | DresserDiamondType | Dresser Diamond Type |

| #9018 | X Position Diamond 1 | X1DressPosition | X1 Dress Position |

| #9019 | Z Position Diamond 1 | Z1DressPosition | Z1 Dress Position |

| #9020 | X Position Diamond 2 | X2DressPosition | X2 Dress Position |

| #9021 | Z Position Diamond 2 | Z2DressPosition | Z2 Dress Position |

| #9022 | X Position Diamond 3 | X3DressPosition | X3 Dress Position |

| #9023 | Z Position Diamond 3 | Z3DressPosition | Z3 Dress Position |

| #9024 | Tip Radius Diamond 1 | ||

| #9025 | Tip Radius Diamond 2 | ||

| #9026 | Tip Radius Diamond 3 | ||

| #9027 | Infeed Angle | ||

| #9028 | Feed Factor 1 | ||

| #9029 | Feed Factor 2 | ||

| #9030 | Xsw Safety Position | SafetyPositionXsw | Safety Position Xsw |

| #9031 | Zs Safety Position | SafetyPositionZs | Safety Position Zs |

| #9032 | Xsd Safety Position | SafetyPositionXsd | Safety Position Xsd |

| #9033 | Deta X Safety Clearance | SafetyClearanceCircumference | Safety Clearance Circumference |

| #9034 | Deta ZL Safety Clearance | SafetyClearanceLeftSide | Safety Clearance Left Side |

| #9035 | Deta ZR Safety Clearance | SafetyClearanceRightSide | SafetyClearance Right Side |

| #9036 | X Return Clearance | ||

| #9037 | Z Return Clearance | ||

| #9040 | Current Commanded RPM | ||

| #9041 | Wheel Dressing SFM | WheelDressSFM | Wheel Dress SFM |

| #9042 | Rotary Dresser Roll Diameter | RotaryDresserDiameter | Rotary Dresser Diameter |

| #9043 | Rotary Dresser SFM | RotaryDresserSFM | Rotary Dresser SFM |

| #9044 | Rotary Dresser RPM | RotaryDresserRPM | Rotary Dresser RPM |

| #9045 | Current Rotary Dresser Rpm | ||

| #9046 | X Dresser Offset (Optional) | RotaryDresserXDresserOffset | Rotary Dresser X Dresser Offset |

| #9047 | Rotary Dresser Maximum RPM | RotaryDresserMaxRPM | Rotary Dresser Max RPM |

| #9048 | Wheel Speed Mode | SurfaceFeetPerMinMode | Wheel Surface Feet Per Min Mode |

| #9049 | Rotary Dresser Surface Feet Per Min Mode | RotaryDresserSurfaceFeetPerMinMode | Rotary Dresser Surface Feet Per Min Mode |

| #9050 | Rotary Dresser Direction (0 = FWD,1 = REV) | RotaryDresserDirection | Rotary Dresser Direction |

| #9051 | Teach New Wheel Dresser Offset 1 | TeachNewWheelDresserOffset_1 | Teach New Wheel Dresser Offset 1 |

| #9052 | Teach New Wheel Dresser Offset 2 | TeachNewWheelDresserOffset_2 | Teach New Wheel Dresser Offset 2 |

| #9057 | New Wheel Offset (0 = Off, 1 = On) | ||

| #9058 | Dresser User Offset 1 | DresserUserOffset_1 | Dresser User Offset 1 |

| #9059 | Dresser User Offset 2 | DresserUserOffset_2 | Dresser User Offset 2 |

| #9060 | Wheel Type (0 = OD, 1 = ID) | WheelTypeODID | |

| #9080 | Current Cycle State | ||

| #9081 | Current Cycle Type | ||

| #9082 | Current Cycle Passes Remaining | ||

| #9083 | Parts Per Dress Cycle | ||

| #9084 | Parts Since Last Dress Cycle | ||

| #9085 | Part Count On Last Dress Cycle | ||

| #9086 | Parts Per Dress Cycle Enabled | ||

| #9100 | Work Head Diameter |

Active Flagging Memory

|

#9230 |

Active Flag X Swivel Position (Machine Zero) |

| #9231 | Active Flag Z Swivel Position (Machine Zero) |

|

#9232 |

Active Flag Tip Diameter |

| #9233 | Active Flag Fast Feedrate |

| #9234 | Active Flag Slow Feedrate |

| #9235 | Active Flag Back-Off Distance |

| #9236 | Active Flag Z- Probe Offset |

| #9237 | Active Flag Z+ Probe Offset |

| #9238 | Active Flag X Measured Position |

| #9239 | Active Flag Z Measured Position |

Global Memory

|

#9250 |

Angle of last grind cycle |

| #9260 | Relieve Amount |

| #9261 | In Cycle Re-position Feedrate |

| #9262 | In Cycle Re-position Clearance Amount |

GCode Parameters

|

1900 |

Gap Control |

| 1910 | Wheel Diameter Lock (1 = Lock, 0 = Unlock) |

|

1911 |

Wheel Width Lock (1 = Lock, 0 = Unlock) |

| 1915 | Dress at wheel Working Angle (0 = Dress equal amount X and Z, 1 = Z Dress amount calculated using wheel Working Angle) |

| 1916 | Dresser Location (1 = Dresser is mounted in front of the wheel, -1 = Dresser is mounted behind wheel) |

Cycle Types

Warranty Information

MachMotion warranty policy is subject to change. Updated information is available at our website:

https://machmotion.com/warranty

The MachMotion Team

http://www.machmotion.com

14518 County Road 7240, Newburg, MO 65550

(573) 368-7399 • Fax (573) 341-2672