2000 Series Knee Mill Installation

This installation manual shows you how to install your 2000 Series knee mill control kit (KT-2050M-RP).

Mount Back Panel

Remove old components

- Remove everything in the electrical enclosure besides the original transformer.

- Measure the size of your current electrical enclosure. The new back panel is 21" x 21". If your electrical enclosure is too small you will also have to remove the original door switch.

- Remove the old cables running to the motors.

Mount the new panel

- Drill holes into the old back panel.

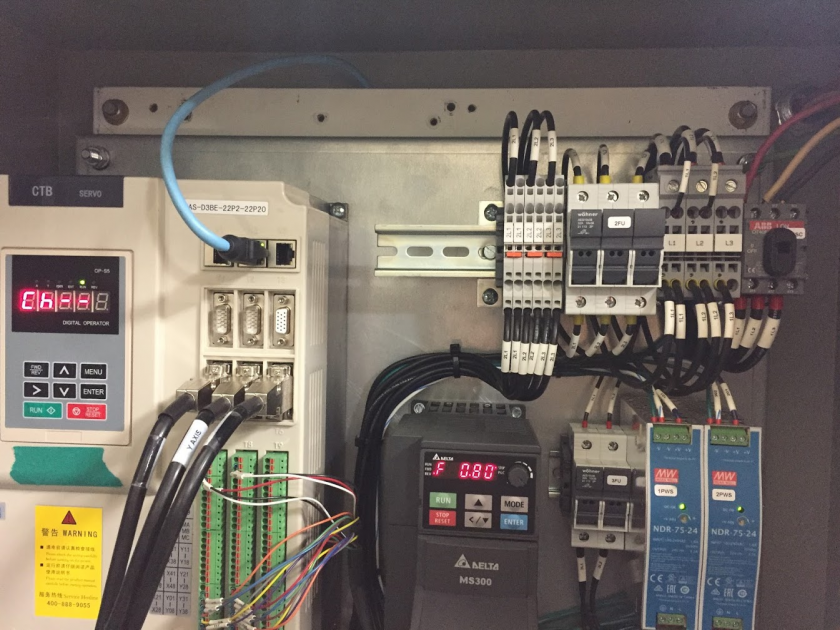

- Mount the new panel onto the original back panel. It should look like this:

- Mount the brake resistor to the wall of the electrical enclosure but close enough so the cables will reach the VFD.

Mount Control

See the 2000 Series Mounting Arm Manual to mount the arm and control.

Connect Control and Power

Connect Cables to the Control

- Remove round, rubber plug from the back of the control. Run conduit from the control to the back panel.

- Connect ethernet cables, power connector cable, and E-stop cables into the control as shown below. (For panels with the Delta VFD, there will only be 2 E-stop leads instead of 4.)

Connect Cables to the Back Panel

- Connect light blue "EtherCAT" cable into N2 on the CTB servo drive.

- Connect the green "Machine Network" cable into the VFD. Depending on the version you may have a Delta MS300 or a Yaskawa V1000.

- Connect the blue "Internet" cable to your local network if you do not plan to use the built in WiFi. Internet is not necessary to run the control. However, help from our support team will be greatly limited without access to the internet.

- Connect the HMI control Power Connector cable to PC 24V, PC 0V and GND blocks.

- For the Delta drive, connect two E-stop leads to the terminal blocks on the back panel as shown below. For E-stop, one wire should run to the 24V block and one wire into the E-stop block.

- For the Yaskawa drive, connect four E-stop cables to the E-10, E-11, E-20 and E-21 blocks as shown here.

- For the Yaskawa drive, connect four E-stop cables to the E-10, E-11, E-20 and E-21 blocks as shown here.

Note: If you have an additional external E-stop, wire it in series with the control E-stop. You will need to connect your external E-stop into the 24V block and the other side into the blank terminal block. Then connect the red wire from the control E-stop into the blank terminal block as well. Finally, put the black wire from the control E-stop into the terminal block labeled E-Stop.

Wire Incoming Power

- Wire incoming power to the back panel into the top of the door switch. Be sure you are bringing in the 208-240VAC. The back panel can run on single phase or 3 phase.

- Note the max spindle motor power limitations:

- 5hp spindle motor with three phase power

- 3hp spindle motor with single phase power

- Note the max spindle motor power limitations:

- Connect the transformer. Start by identifying the primary and secondary side of the transformer. The transformer will be fed with 240VAC and we need 120VAC output. If the transformer doesn't have clear markings and your machine doesn't have a schematic, you may have to google the transformer part number to figure out how to wire it.

- Connect primary side of the transformer to 240VAC from the two 4FU fuses shown below. Then connect the secondary side to 5CB and terminal 502.

- Make sure to ground the secondary side of the transformer. In the example above, you would ground X2.

- Make sure to ground the secondary side of the transformer. In the example above, you would ground X2.

Mount Motors

Mount the motors to the machine using the motor mounting plates provided. If possible, take a look at the gears and write down the number of teeth on the motor gear and the ball screw gear. If you write down the gear ratio specifications, ball screw pitch, etc. now, it will make calibration much faster later.

Run Cables

Route Motor Cables

Run the motor cables (Encoder and power) from the motors to the back panel. If the machine was equipped with CNC components before the retrofit the cables can usually follow the path of the old motor cables.

Take care when running the cables to keep them away from pinch points and sharp edges. The cables are protected by robust insulation but repeated wear and tear will cause damage and eventual failure. If the cables must run over a possible wear point, use some form of loom for additional protection. Keep in mind the motion of the machine and possible cable snag points while the machine is moving.

Connect Cables to Drive

There are two cables that come from each motor. One is for motor power and the other is motor encoder.

The X motor power cable (U,V,W,GND) will need to be wired into U1, V1, W1 and GND. The X motor encoder cable will need to be plugged into T4. See the below diagram

The Y motor power cable (U,V,W,GND) will need to be wired into U2, V2, W2 and GND. The Y motor encoder cable will need to be plugged into T5. See the below diagram

The Z motor power cable (U,V,W,GND) will need to be wired into U3, V3, W3 and GND. The Z motor encoder cable will need to be plugged into T6. See the below diagram

Wire Spindle Motor

Determine if your machine has the Delta MS300 or the Yaskawa V1000 VFD.

Delta MS300

- Remove the cover from the Delta MS300 VFD as shown.

- Connect your spindle motor to the terminals labeled U/T1,V/T2, and W/T3 as shown in the below image.

- Connect the two leads from your brake resistor to +2/B1 and B2 terminals on the VFD as shown in the figure below.

Yaskawa V1000

- Loosen screw and remove outer plastic cover.

- Press tab to remove second plastic cover.

- Connect your spindle motor to the terminals labeled U/T1,V/T2, and W/T3 as highlighted in the below image.

- Connect the two leads from your brake resistor to B1 and B2 terminals on the VFD as shown below.

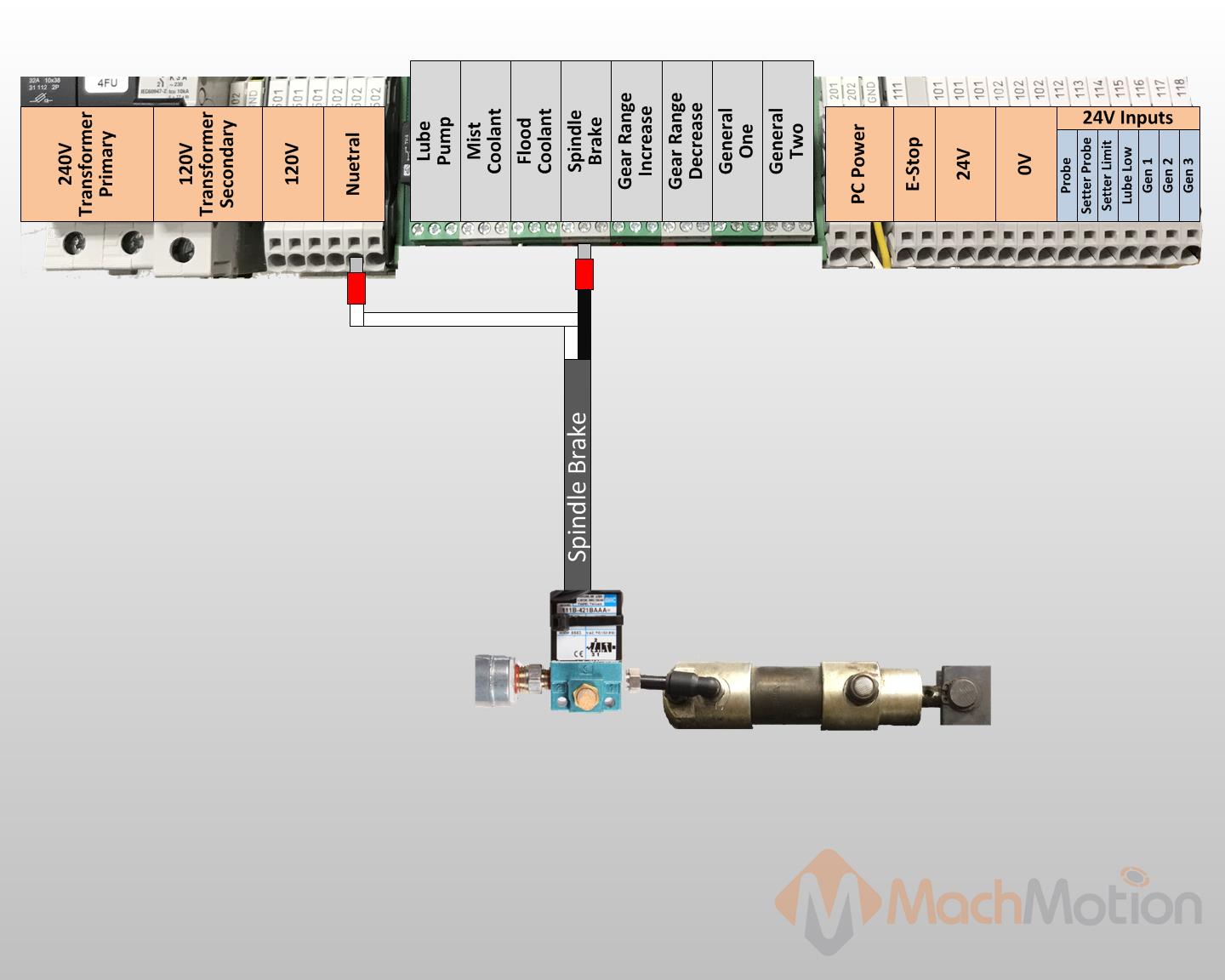

Wire Inputs and Outputs

Wire any inputs and outputs as shown in the diagrams below.

Output Commons

Please note, the output common comes pre-jumpered to the 120v circuit to the left of output wiring block as shown below. Verify the voltage of each output destination before wiring. If any of your outputs run on 24VDC, make sure the output common for that output is jumpered to 24V.

Wiring Lube System

Wiring Coolant System

For a contactor with 120VAC coil, wire it as shown.

Note: The contactor shown above is not included. Use the original contactor on your machine.

Coolant Pump Power

You can power up to a 0.5 hp 3 phase coolant motor. To run a 3 phase motor, the back panel will have to be powered with 3 phase. Run 3 wires from 2L1, 2L2, and 2L3 on the top of the back panel to the contacts on on your contactor.

Wiring Spindle Brake

Wiring Tool Setter

Wiring Probe

Power System Up

Carefully inspect incoming power to make sure it is within range for your system. Most systems use 208-240 VAC.

We recommend utilizing a Multimeter to check incoming power. If using 3 Phase, check all 3 phases.

- Turn the door switch on.

- Check the transformer is outputting the correct voltage as well.

- Run motion on the machine

- Lower the jog rate using the knob on the control

- Carefully jog each axis. Confirm that they are traveling in the right direction. You can verify your axis direction using this diagram. It's based off of the right hand rule. Make sure to reference the TOOL and not the table movement.

- Lower the jog rate using the knob on the control

-

- If a motor is traveling in the wrong direction it can be easily reversed in the Mach4 software. First you will need to make sure your control is Disabled. Navigate to the top left of the screen and click Configure>Control and then click on the Motors. Select the problem motor and check the Reverse check box.

- Test inputs and outputs

The best way to do this is use the buttons already setup for the intended function. For example, "Coolant" has a hard button on the control. You can also toggle signals manually by going to the Service tab, then Machine I/O. Double clicking on a signal will change its state. Double click again to change it back.

Configure Software

There are two options for setting up units and soft limits. Typically, the easiest way is to use the MachMotion Knee Mill Setup Wizard.

Knee Mill Setup Wizard

Select the Kneemill Setup Wizard from the Configure drop down on the main menu. This will guide you through an initial setup process that will allow you to set axis unit calibration, soft limits, and spindle calibration. You can also go through each step manually by following the information on completing the set up process for Units Calibration and Homing and Soft Limits outlined below.

Upon selecting the Kneemill Setup Wizard, you will be presented with a selection of configuration options. Yellow triangles indicate which features have not been completed yet, and green check marks correspond to previously completed items. It is suggested to do the items in the following order:

- Units

- Softlimits

- Spindle Calibration

- Backlash

Units

To set the units for each axis, the pitch of the ballscrew, the number of teeth on the ballscrew pulley, and the number of teeth on the motor pulley must be known. An advanced option is available for other systems of motion or if the data is not known.

The wizard will go through each axis individually in order (X, Y, Z). For each axis, you must enter the three pieces of data. Every time you change the data, the new units will be calculated and applied to the axis. To verify the units, a 1" dial indicator can be used. The wizard supplies options to move the axis back and forth distances up to an inch. Otherwise, verification can be done by manually jogging or commanding MDI motion.

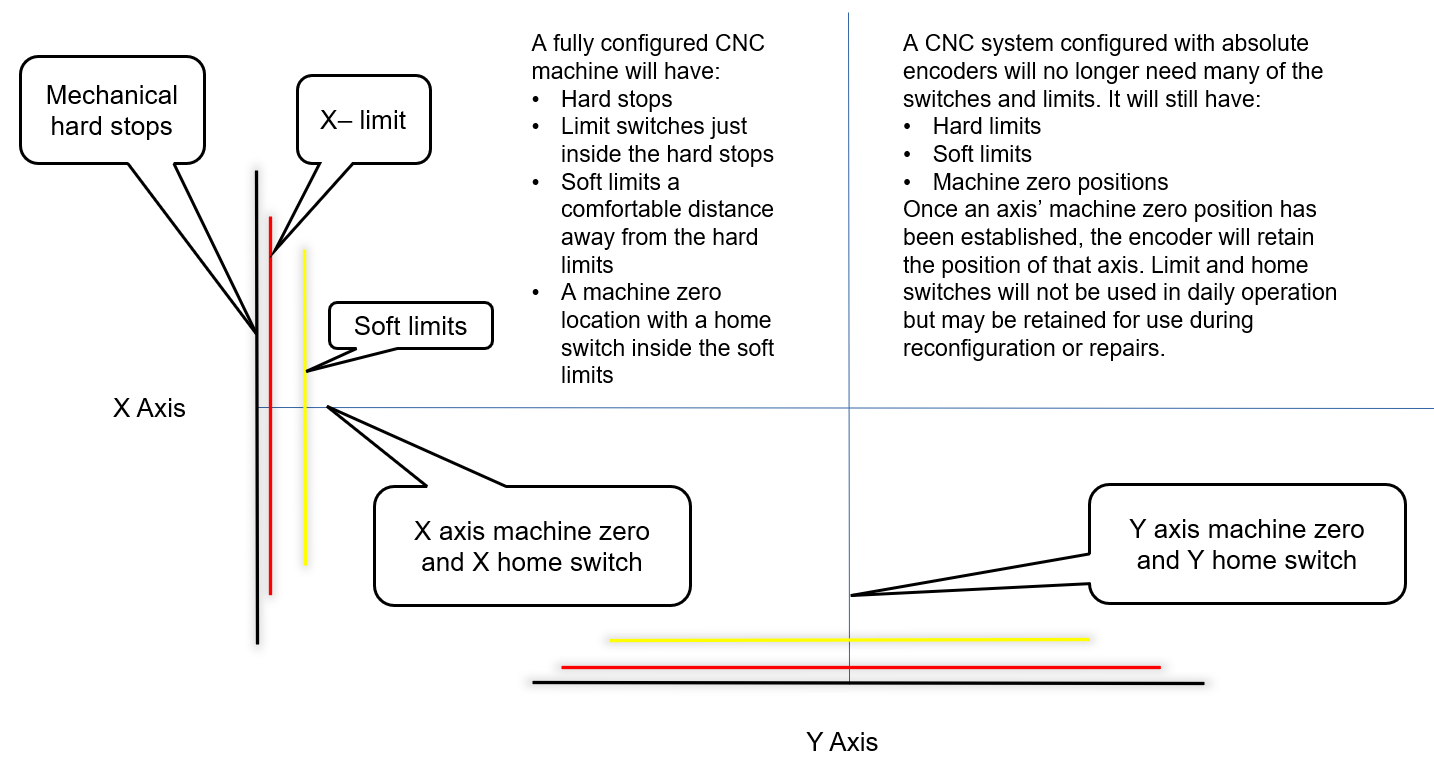

Soft limits

It is suggested to go through this part with the machine disabled and to use the handwheels to move the machine. It is possible to move the machine with the jog functionality or pendant if the speed is turned down and caution is used.

Use extreme caution when jogging the machine. Until the soft limits are set it is possible to run an axis to its hard limit.

The softlimits wizard will go through the three axes in order (X, Y, Z) and ask you to move the machine first to maximum travel and then to minimum travel. The positions should be within machine physical limits and within any limit switches on the machine, but should encompass most of the usable machine.

For each position, you will either need to select Set Softlimit or Skip in order to proceed. As you move through the wizard, the image will change to help you visualize the correct positions. When you set the maximum softlimits for each machine, the control will set your Home position to the same place, unless the machine has previously been homed.

For reference, while facing the machine, X maximum travel is with the table all the way to the left and the spindle nose all the way to the right of the table. Y maximum travel is with the table as close to the operator as it can go and the spindle nose near the far edge of the table.

After exiting the wizard, limits will be activated. It is now possible to enable the machine and jog the axes into their limits. When the limit is reached, the machine will cease moving in that direction. It is a good idea to turn down the jog rate and test the limits at this point.

Use extreme caution while testing limits in the event that an axis was accidentally skipped or set at an incorrect position.

VFD Setup

Your Variable Frequency Drive will need to be calibrated for your motor. This can be done directly from the operating software. Under the Service tab, click the "Interface Config" button.

Now, search for your VFD. In the search bar (top bar outlined in red below), type in the model that came with your cabinet. It is either a "Yaskawa V1000" or a "Delta MS300." That will bring up the editable parameters (shown in the lower red box below). Simply highlight the value to change it. Many of these values may be able to remain the default ones.

You can find out what parameters need to be changed by looking at the info on your spindle motor name plate. Check and change any of the values that need it (Number of poles, wattage, amperage, etc.) to make sure your spindle runs at peak performance.

Spindle Calibration

The spindle calibration wizard requires you to read the specifications from the spindle and insert them into the wizard. The information needed is the maximum RPM for low gear, the maximum RPM for high gear, and the amps for full load. These should be input and then Save selected.

The spindle can be tested by inputting a spindle speed on the screen and then pressing the Spindle FWD or Spindle REV buttons on the panel. If the spindle is turning the incorrect direction, the Reverse spindle direction check in the wizard can be toggled. Be sure to select Save.

If you want to calibrate your spindle with a tachometer, please see the VFD - Spindle Calibration documentation.

Backlash

In the case that you have less then .0005" of backlash, this step may be skipped. Backlash compensation will not completely compensate for all mechanical deficiencies.

Be sure to start this wizard with each axis near the middle of travel. The machine needs minimum of 1" of travel in all directions for this wizard to succeed.

The wizard supplies buttons for moving the machine positive and negative 1 inch, input for the amount of error, and an indication of direction of error.

For each axis, move the axis negative and then attach a dial indicator and zero it. Then move the axis positive once. Input the error from the indicator and select the direction of error. Then select Calculate & Apply. Verify the backlash by repeating the process until the machine is consistent.

Manual Setup

Units Calibration

Before the machine is homed or any further setup is completed we must calculate our steps per/unit and calibrate the motors accordingly. Mach Motion has a plugin to streamline this process.

- If you know the gear ratios, ball screw pitch, etc of your machine, use the Automatic Calibration shown here:

- Open Configure>Plugins>Machine Calibration

- Select Automatic Calibration

- For each axis, select the drive used for that axis, input the machine configuration, press Calculate, then Accept

- Close the calibration window

- Open Configure>Plugins>Machine Calibration

- If you do not know the gear ratios, ball screw pitch, etc of your machine, use the manual calibration shown here:

- Open Configure>Plugins>Machine Calibration

- Select Manual Calibration

- Select Commanded Distance

- Input 1 in the 'Distance to move axis' field for a movement of 1"

- If the machine is setup with metric units, enter small metric value instead

- For each axis, do the following:

- Setup a dial indicator for positive 1" machine travel, or your metric value

- Enable the machine

- Press the Move button

- Input the distance actually moved in the 'How far did the axis move' field

- If the machine is metric, be sure to enter distance traveled in millimeters

- Press Submit, then Accept

- Setup a dial indicator for positive 1" machine travel, or your metric value

- If you will be producing larger parts, run the manual calibration again, but use a longer distance of travel. It will need to be a distance that you can measure accurately. This will provide improved accuracy.

Homing and Soft Limits

With the motor units calibrated, we can now set the machine zero and set up the software limits.

Machine zero is used by the control for all movement calculations, but you will not typically use it directly. Your RPKM system has absolute encoders that maintain the position of each axis even when the machine is powered down. We will set the machine zero here once and you will not need to home your mill when you start it up.

- Go to your service tab. Turn off soft limits, enable and ensure that your axis labels are flashing red and yellow. If not, please call MachMotion for assistance de-referencing your axes.

- Carefully jog X and Y to the negative hard limits, then jog it back into where you want your soft limits, and come in just a little more to where you want your machine zero on each axis.

- Do the same with the Z axis. Carefully jog it all the way up to the hard limit. Jog down to your soft limit position, and then down a little more for your Z machine zero.

-

- Navigate to the Service Tab and click Home All. This sets the machine zero for all axes. If the Home All button is not active, please call MachMotion and we will help you de-reference all axes so that you can set your machine zero.

- Next we need to set up the soft limits to prevent crashes. On the upper left hand side of the screen select Configure and then Config Soft Limits.

- Follow the prompts listed. Soft limit set up can be done on all axes at the same time.

Backlash Compensation - Manual Configuration

- Move an axis in one direction farther than the maximum possible backlash.

- Mount a dial indicator and zero it.

- Move the axis again in the same direction for a specific distance (it doesn’t matter how far).

- Move the axis backwards the same distance.

- Note how far the dial indicator was off from zero to see the axis’s backlash value.

- On the menu bar go to Configure->Plugins->RapidPath-MachMotion

- On the top right of the page, click the Drives tab

- Select which motor you set the backlash on from the list on the left.

- Enter calculated backlash distance in the Backlash Rate field.

- If you are unsure which motor is on which axis, selecting the motor will show what axis it is assigned to.

Lubrication Pump

Your kit is pre-configured with a relay to control the Lube Pump, as seen above. You can change the frequency and duration of which it runs in the MachMotion parameters.

Under the Service tab, click the "Interface Config" button.

Then search "Lube"

Additional Documentation

If you are just setting up your machine and getting used to the 2000 series control, check out these other manuals to learn how to use the control PC, operator panel and Mach4 Software.

For more info on the Control and Operator Panel, check out the "2000 Series HMI" (Human-Machine Interface) manual.

For information about Mach4 Software Operation please see "2000 Series Mill / Router Operating Manual"

Warranty Information

MachMotion warranty policy is subject to change. Updated information is available at our website:

https://machmotion.com/warranty

The MachMotion Team

http://www.machmotion.com

14518 County Road 7240, Newburg, MO 65550

(573) 368-7399 • Fax (573) 341-2672