2000 Series Dual Table

Router Dual Table

Dual Table is a feature that can used on machines with an overhead axis that normally holds the spindle and Z axis. The machines have the capability to run a program on ether table or link both tables together to make one large table. There is a second feature Table Auto-Switching that can be used to select two programs one for the right table and one for the left table and at the end of the program the control will park the table that was just being used and auto load the program for the other table.

Table Layout

The control supports three configurations for the tables, Table 1, Table 2 and Table 3. Each mode will reconfigure the motors so that the same axis will control all three configurations. Most commonly the Y axis is used for the table, the example below uses the Y axis for all three options.

Table 1 and Table 3 use Work Offset G54, Table 2 uses G55. The Work Offsets are activated along with the tables.

Enable and Setup Dual Table

On Mach builds older than 5431 the MotionFilter plugin must be enabled for dual table to function properly.

This document is expecting that the two tables axes have been setup with Limits, Homing and Units calibrated. The motors should be mapped to two different axes with Software limits turned on.

Setup Machine Parameters

Turn on the Dual table feature from the Machine Parameters. Search for 'dual' and set the following parameters:

- Dual Table Enabled = Yes

- Dual Table Master Axis ID = 0-5 This is the Axis that you plan to use in the program to move the tables. (X = 0, Y = 1 ect.)

- Dual Table Slave Axis ID = 0-11 This is a un-used axis that the machine needs when aligning the tables. (A = 3, B = 4, OB1 = 6, etc.)

- Dual Table Master Motor ID = 0-31 This is the motor that controls Table 1. See Table Layout.

- Dual Table Slave Motor ID = 0-31 This is the motor that controls Table 2. See Table Layout.

When the control switches from Table 1 to Table 2 the tables need to move to a park position before swapping the motors around. Enter the Machine Coordinate position for this park position into the Dual Table Axis Park Position parameter.

Work Offset Setup

We need to make sure that when reset is pressed we are not activating a work offset. When Dual Table is enabled we want to allow the Table selection to select G54 for Table 1 and Table 3 and G55 for Table 2.

When done press Save to close the window.

You will still need to setup Work Offset G54 and Work Offset G55 by first selecting a table and then going to the Fixtures page at the bottom of the screen and jogging the machine to the corner you want to use as zero and zeroing there.

Dashboard Setup

We are ready to add the Dual Table widget to the Side Bar Dashboard. To learn more about dashboards see Dashboards.

Now we should have the Dual Table widget displayed.

Operation

When Table Auto-Switching mode is off, operating a Dual Table machine is very similar to a single table machine with the option of selecting to run a part on the right table, left table or one large table.

What happens when a table is activated:

| Table Name | Work Offset | Axis Controlling Table | Description |

| Table 1 | G54 | *Master Axis ID | The table on the right moves with the GCode program |

| Table 2 | G55 | *Master Axis ID | The table on the left moves with the GCode program |

| Table 3 | G54 | *Master Axis ID | The right and left tables are slaved together to make one large table, and they move with the GCode program |

*Master Axis - The axis ID assigned to the Dual Table Master Axis ID parameter. See Setup Machine Parameters.

You can modify what happens in Setup Machine Parameters if you want different functionality than this. For example, you can use G52 Y60 to do a global shift (shift all offsets) by 60".

Activating Tables

To select a table click on the small icon buttons for table 1-3.

You will get a window that will confirm you want to activate a table. Press the Cycle Start button to continue.

When a table is active the Label below the button should be green.

Table Auto-Switching

Table Auto-Switching is a feature that will allow you to select two GCode files and when the file ends on a M30 the control will move the tables to the park position swap motors and load the next file. Running this way allows the operator to load parts on the idle table while the machine is running on the other table. Table Auto-Switching is not allowed when Table 3 is active.

To Activate Table Auto-Switching press the button at the bottom of the widget. When the button is green Table Auto-Switching is on.

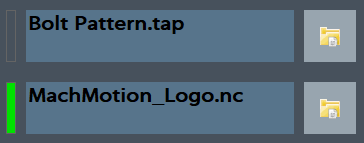

To select GCode files to run on Table 1 or Table 2 press the folder icon buttons. The first row is the file that will run on Table 1, and the second row is for Table 2. The LED indicator to the left of the file name shows the file that will be run when you press Cycle Start.

This is how the widget should look when everything is setup and ready to run. In this example Table 2 is Active and the GCode program that is loaded matches the one assigned to Table 2.

Activating Tables Inside a Program

To activate a Table inside a GCode program call M233 T with the table number. This can only be done when Table Auto-Switching is turned off.

Example:

M233 T2 (Activate Table 2)